Rotor two-gang pressure shaft assembly line

A technology for assembling production lines and rotors, which is applied in the manufacture of stator/rotor bodies, etc., can solve problems such as low efficiency, and achieve the effects of high production efficiency, prevention of crush injury and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

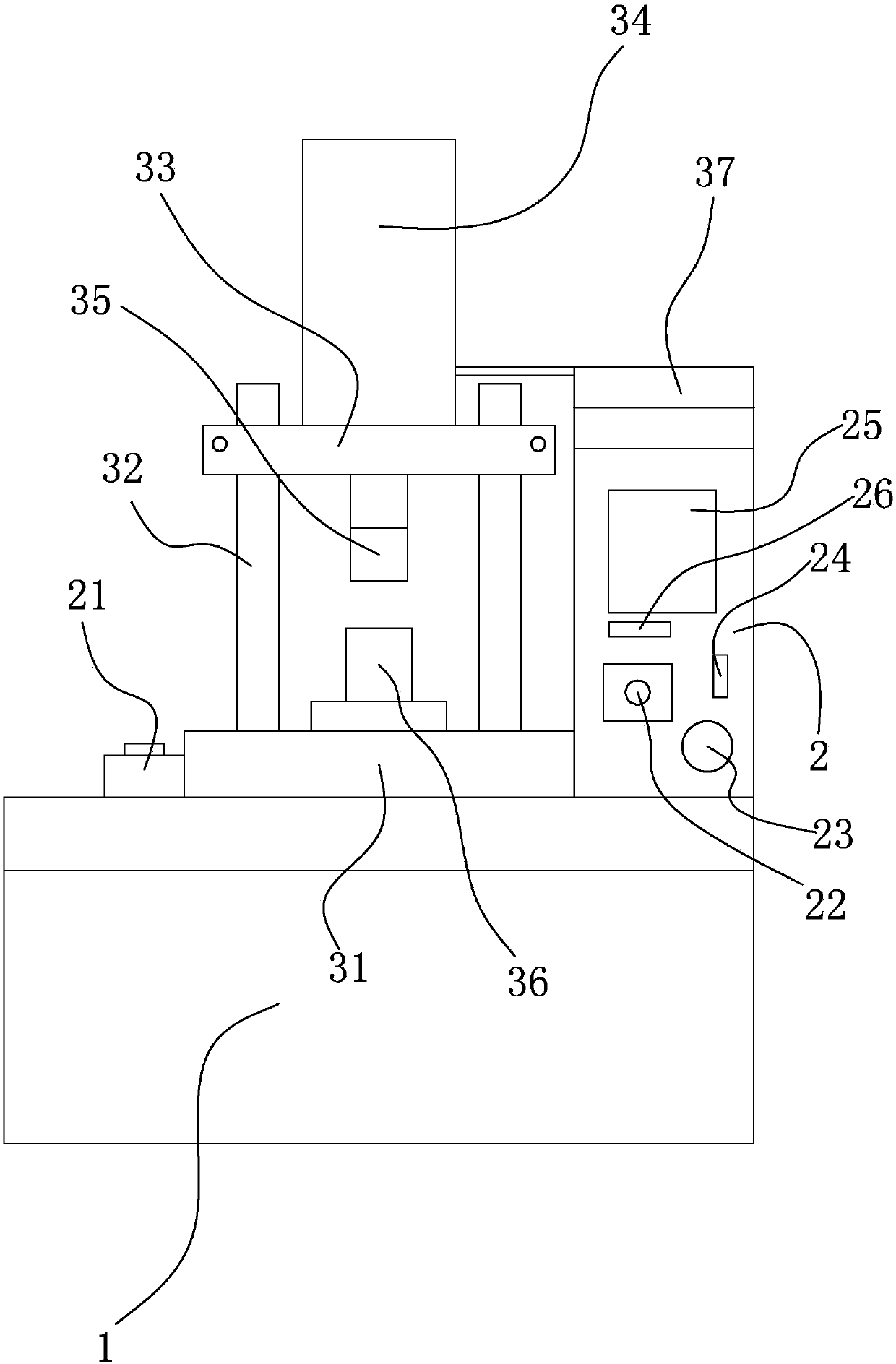

[0013] refer to figure 1 , a rotor duplex finale assembly production line, including a finale device, a conveying device, a baffle press-fitting device and a commutator press-fitting device, the finale device includes an organic base 1, and a finale shaft mechanism is fixedly arranged above the base 1, Press the rotating shaft into the iron core through the finale mechanism, the finale mechanism is electrically connected to the controller 2, and the finale mechanism is controlled by the controller 2, the controller 2 is arranged on the right side of the finale mechanism, and the controller 2 includes a first double switch 21 And the second double switch 22, the first double switch 21 and the second double switch 22 are connected in series, the first double switch 21 is arranged on the left side of the finale mechanism, the second double switch 22 is arranged on the controller 2, the second A double switch 21 and a second double switch 22 are located on both sides of the finale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com