Oven

A technology for ovens and oven doors, which is applied in the field of ovens, can solve problems such as heat loss and user burns, and achieve the effect of improving thermal insulation performance and achieving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

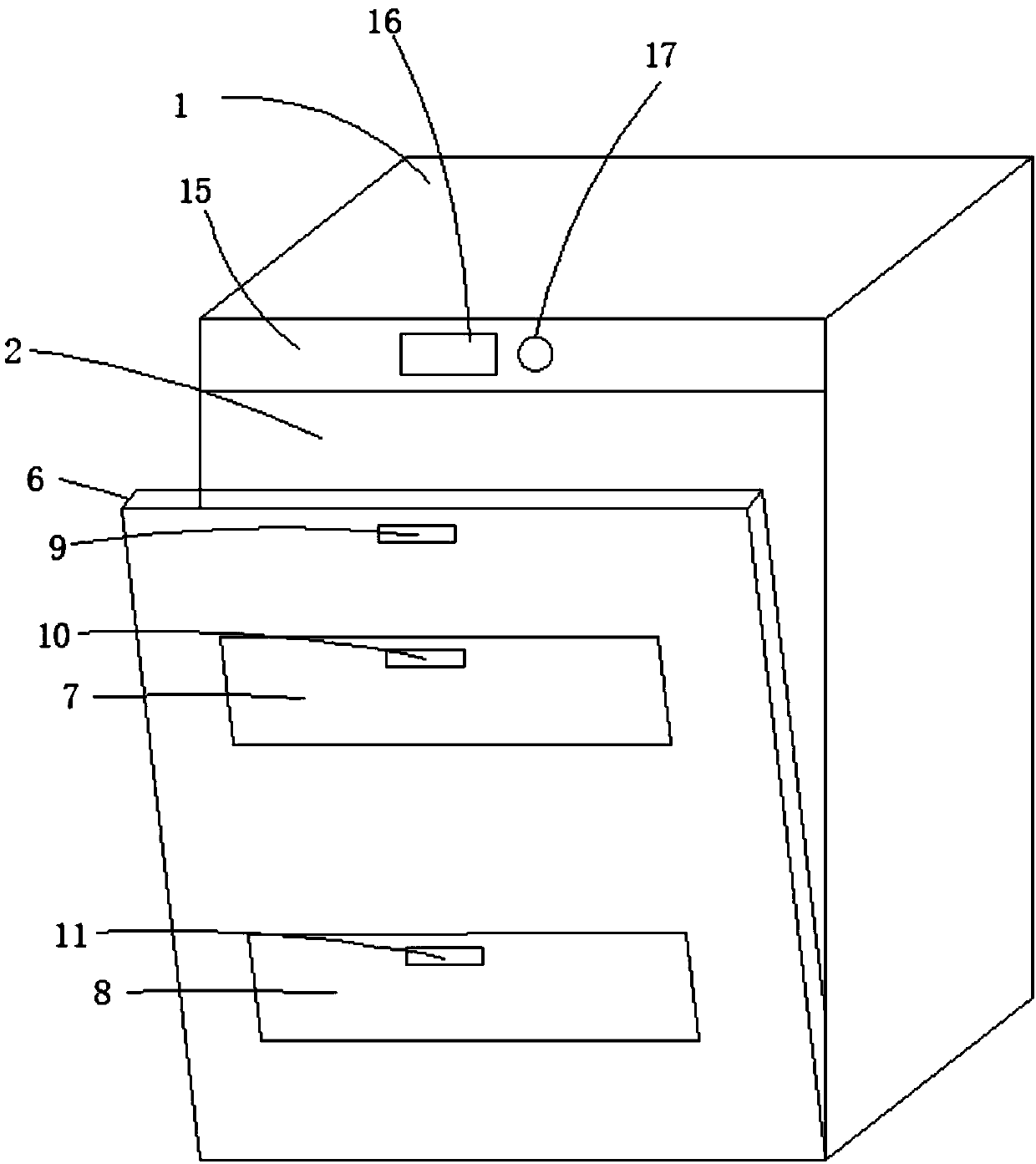

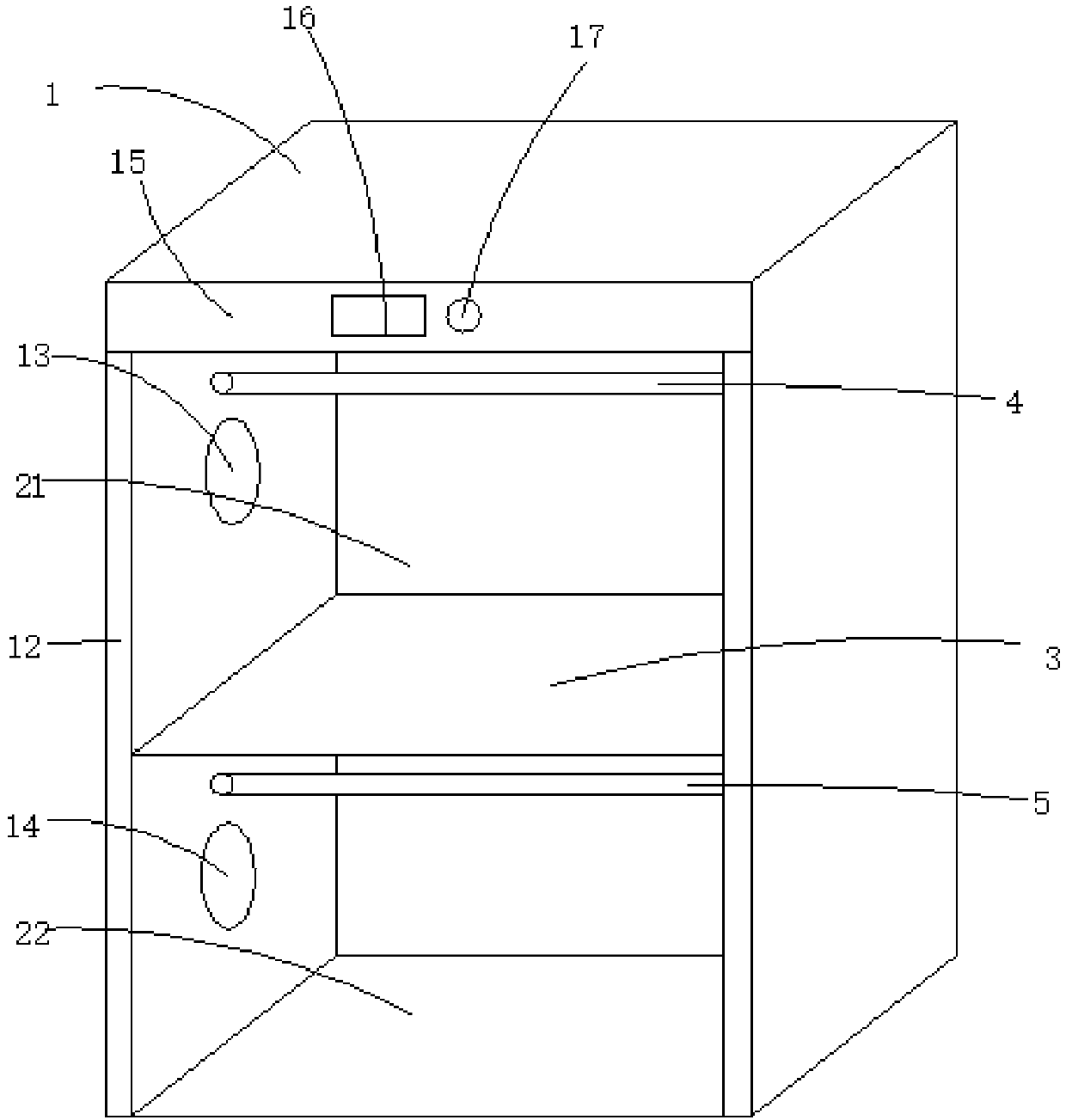

[0026] See figure 1 with figure 2 , The present invention provides an oven, comprising: a housing 1, a cooking cavity 2 formed in the housing 1, a heat insulation plate 3 that divides the cooking cavity 2 into an upper cooking cavity 21 and a lower cooking cavity 22, The first heating tube 4 and the second heating tube 5 respectively provided in the upper cooking cavity 21 and the lower cooking cavity 22, the main oven door 6 rotatably connected with the housing 1, and the respective parts of the main oven door 6 The upper oven door 7 and the lower oven door 8 arranged corresponding to the positions of the upper cooking cavity 21 and the lower cooking cavity 22, the main oven door lock 9 formed on the main oven door 6, and the upper oven door 7 are respectively formed And the upper oven door lock 10 and the lower oven door lock 11 on the lower oven door 8, covering the outer surfaces of the main oven door 6, the upper oven door 7, the lower oven door 8, and the inner surfaces ...

Embodiment 2

[0031] A method for processing heating components of an oven, the steps are as follows:

[0032] 1), structure and separate processing

[0033] The heating component is arranged in the housing, the housing is provided with a cooking cavity, the cooking cavity is equipped with a heating tube, the inner surfaces of the left and right sides of the cooking cavity are provided with heat insulation layers, and the cooking cavity is equipped with a circulating fan;

[0034] The insulation layer is made of polyvinyl chloride foam material;

[0035] Circulating fans and heating tubes are manufactured according to existing technology;

[0036] 2), pre-treatment

[0037] Spray the pretreatment liquid on the surface of the heat insulation layer, and treat it with blast drying for 3 hours after spraying;

[0038] The components of the pretreatment liquid are: 6.5 parts of polyethylene wax, 7.5 parts of polyorganosiloxane, 15 parts of diethylene glycol, 20.5 parts of acrylic resin, and 2.5 parts of sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com