Continuous production equipment for silicon monoxide

A silicon monoxide, equipment and device technology, applied in the chemical industry, can solve the problems of energy waste and inability to realize continuous production, and achieve the effects of improving production efficiency, improving energy utilization efficiency, and convenient cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0011] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

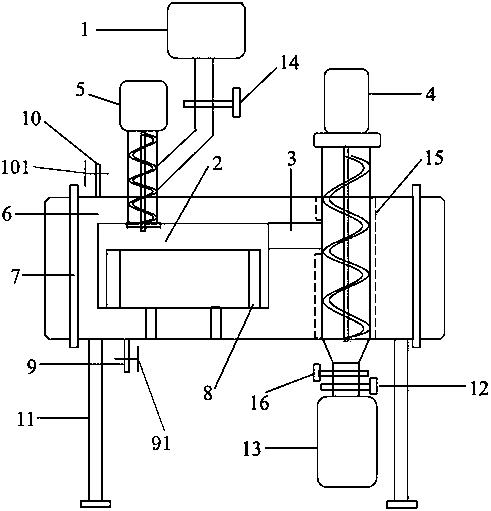

[0012] like figure 1 Shown is a schematic diagram of the overall structure of the present invention, a device for the continuous production of silicon monoxide, including three parts: a furnace body, a vacuum spiral feeding device and a spiral receiving device. The inside of the furnace body is a preparation area for silicon monoxide. The interior includes a reaction zone 2 and a diffusion zone 3. The vacuum screw feeding device is installed on the upper part of the furnace body. The lower end of the vacuum screw feeding device is connected to the reaction zone 2 of silicon monoxide. The diffusion area 3 is connected, the lower end of the spiral receiving device is connected with the receiving tube 13, the furnace b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap