Contact test analysis system suitable for rotary mill cylinder and testing method thereof

A test analysis, contact technology, applied in the direction of grain processing, etc., can solve the problems of increased resistance, insignificant change of resistance torque, easy wear of vane probe, etc., to improve accuracy, meet flexibility and diversity, Avoid Distortion Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

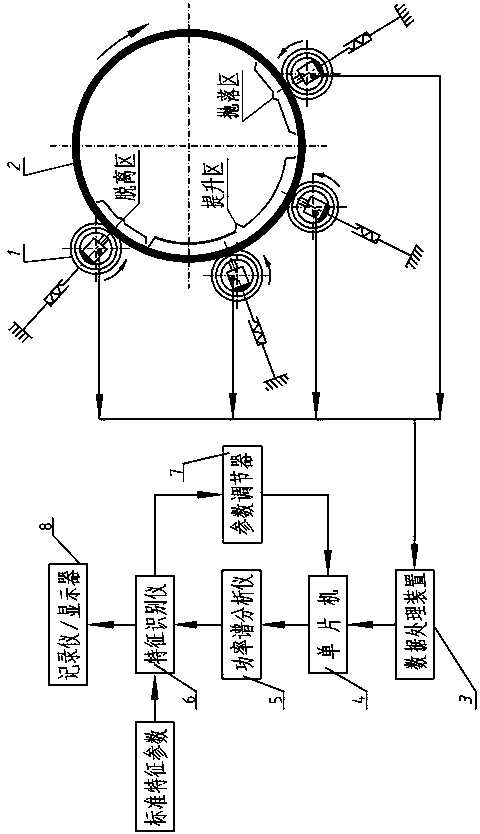

[0038] Example: see figure 1 —— Image 6 .

[0039] The invention discloses a contact test and analysis system suitable for a rotary mill cylinder, which comprises a mill cylinder 2 outside the mill, a rolling monitoring device 1, and the rolling monitoring device 1 and the mill cylinder 2 In rolling contact, the motion signal of the mill cylinder 2 is sequentially connected with the mill data processing device 3, AT89C51 single-chip microcomputer 4, power spectrum analyzer 5, and feature recognition instrument of the online monitoring and analysis system through the rolling monitoring device 1. 6, the output end of the feature recognition instrument 6 is respectively connected with the mill parameter regulator 7 and the recording / display device 8, and the mill parameter regulator 7 is connected with the AT89C51 single-chip microcomputer 4.

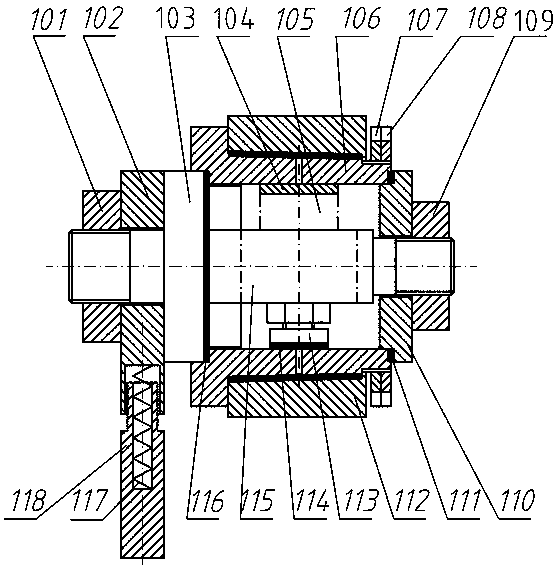

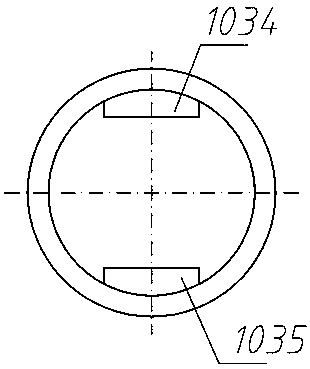

[0040] The inside of the rolling monitoring device 1 is provided with a sensor 105, and a cylindrical stator 106 is fixed outside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com