Centralized supply original-liquid-type cleaning substation

A technology of centralized supply and substation, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of shortening chemical distance, inconvenient switching, inconvenient chemical storage and distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

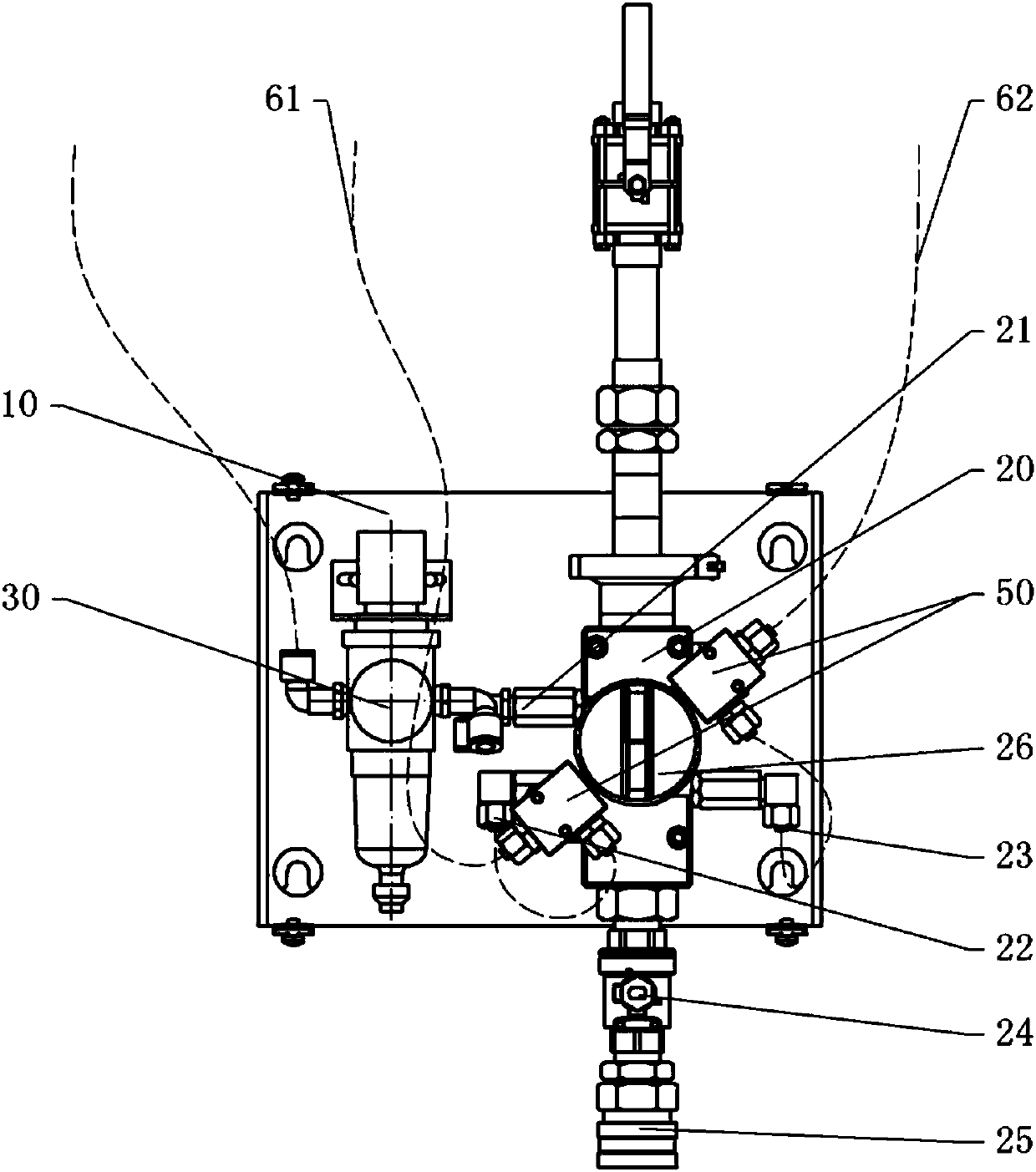

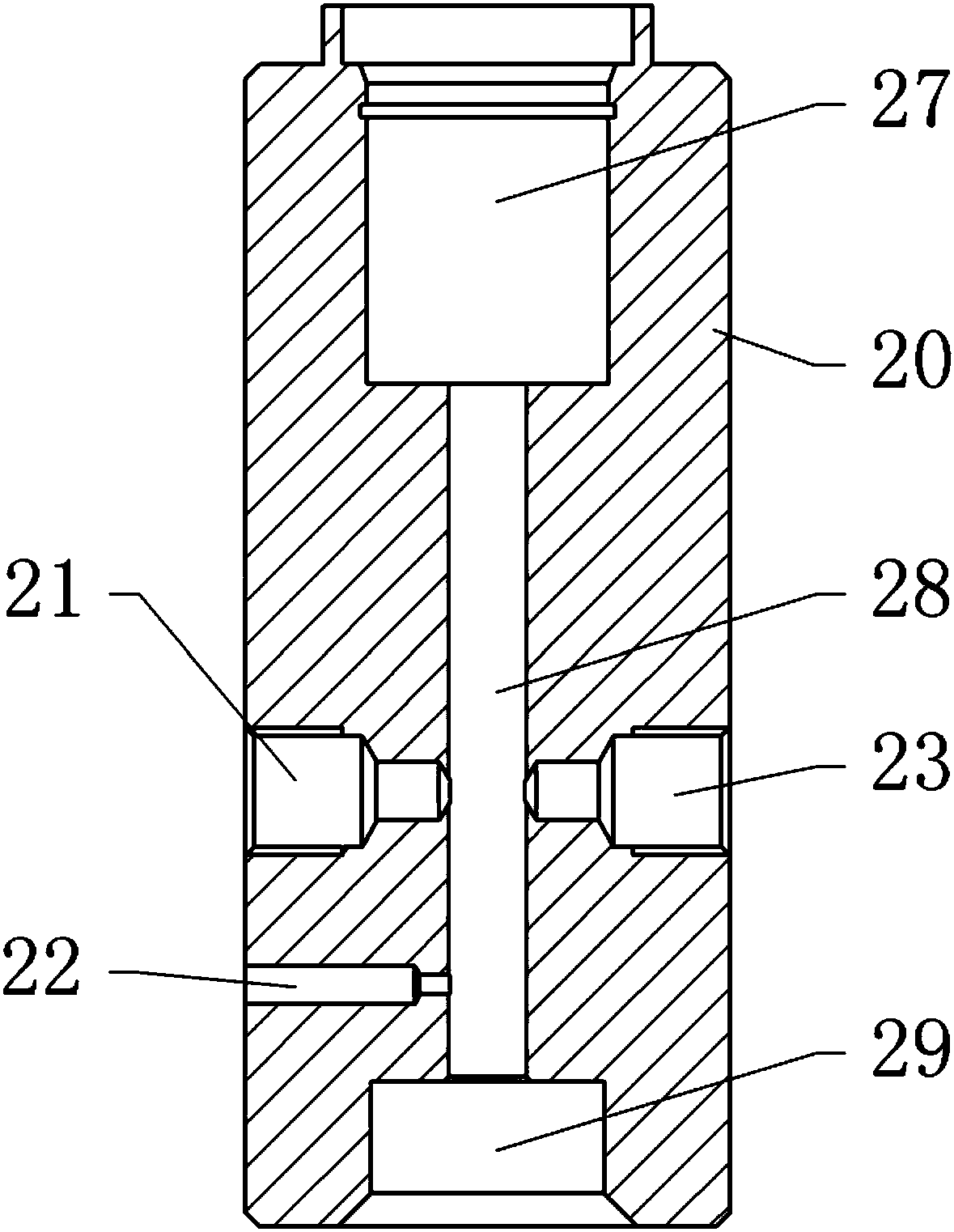

[0022] The reference signs in the drawings of the description include: housing 10, mixing module 20, compressed air inlet 21, foaming agent suction port 22, disinfectant suction port 23, shut-off valve 24, push-in connector 25, knob 26, water inlet port 27. Mixing section 28, water outlet 29, pressure regulating valve 30, valve 50, foam agent pipeline 61, disinfectant pipeline 62.

[0023] Such as figure 1 , figure 2As shown, the centralized supply liquid cleaning substation of this embodiment includes a housing 10, a pressure regulating valve 30 and a mixing module 20 made of 316 / PTFE / PP or fluororubber. The pressure regulating valve 30 and the mixing module 20 are installed in the housing 10. The mixing module 20 is provided with a high-pressure water channel. The two ends of the high-pressure water channel are the water inlet 27 and the water outlet 29 respectively....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com