Vibration type auto parts stamping device and method for stamping using the same

A technology of auto parts and stamping devices, which is applied in the field of vibrating auto parts stamping devices, can solve difficult problems such as improving the forming accuracy of high-strength steel or aluminum alloys or rebound defects, reducing vibration effects, and loosening of sheets, so as to avoid noise And mold collision wear, avoid rebound phenomenon, avoid the effect of wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

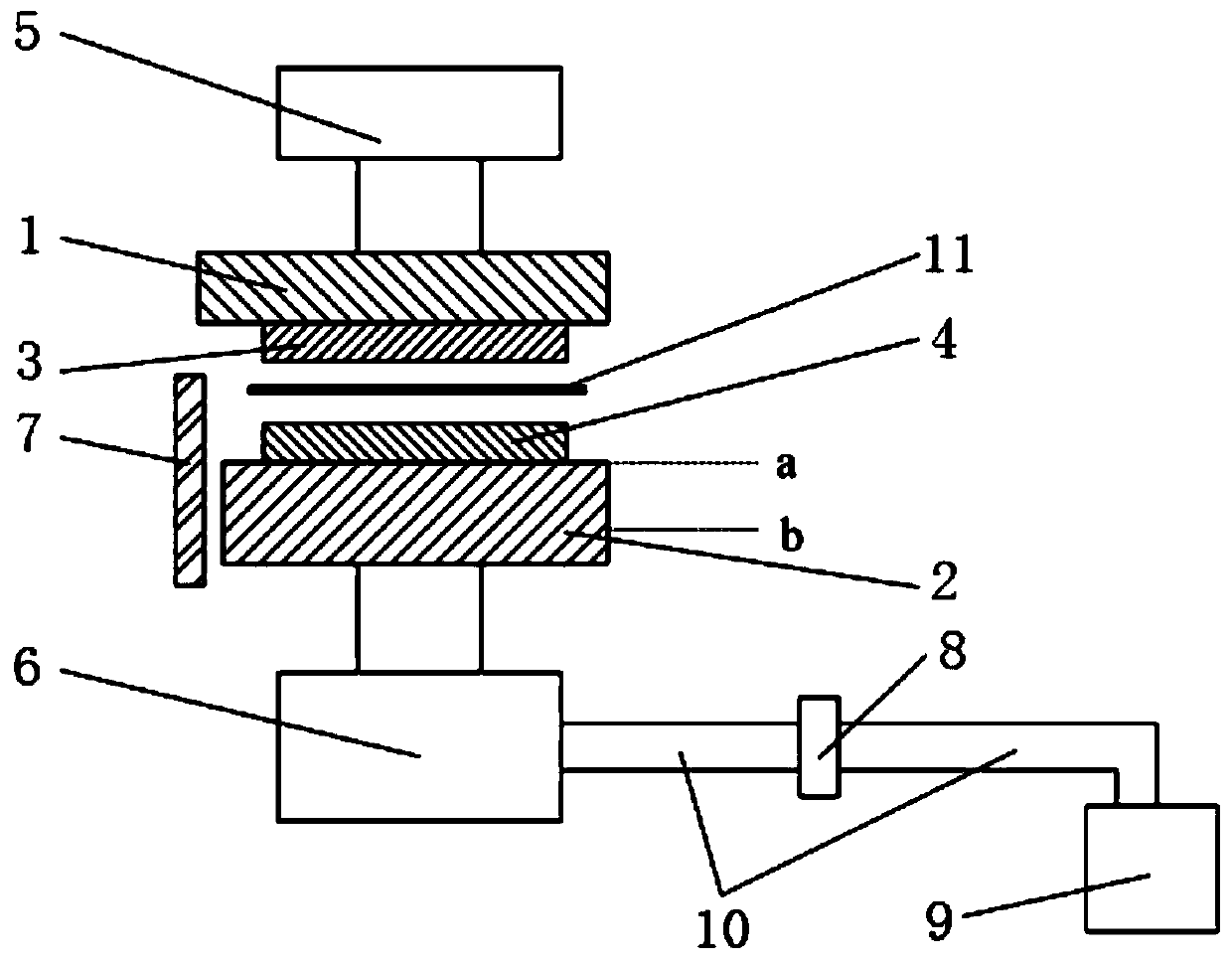

[0029] Such as figure 1 Shown, a kind of vibratory auto parts stamping device comprises an upper workbench 1 and a lower workbench 2 which are arranged vertically oppositely, the lower surface of the upper workbench 1 is provided with an upper die 3, and the lower workbench The upper surface of 2 is provided with a lower mold 4 corresponding to the upper mold 3, and the upper workbench 1 is provided with an upper hydraulic cylinder 5 that drives the upper workbench 1 to move vertically. The table 2 is provided with a lower hydraulic cylinder 6 that drives the lower worktable 2 to move in the vertical direction, a damper 7 is provided on the downward movement track of the upper worktable 1, and the lower hydraulic cylinder 6 is overflowed by electromagnetic The valve 8 communicates with the hydraulic source 9;

[0030] Both the lower hydraulic cylinder 6 and the electromagnetic overflow valve 8 and the electromagnetic overflow valve 8 and the hydraulic source 9 are communicate...

Embodiment 2

[0034] A method of stamping using the vibrating auto parts stamping device described in Example 1. In this example, DP780 steel plate is selected as the sheet material 11 to be stamped, with a tensile strength of about 780MPa and a thickness of 1.0mm. Taking the side wall of an automobile as an example , with the following steps:

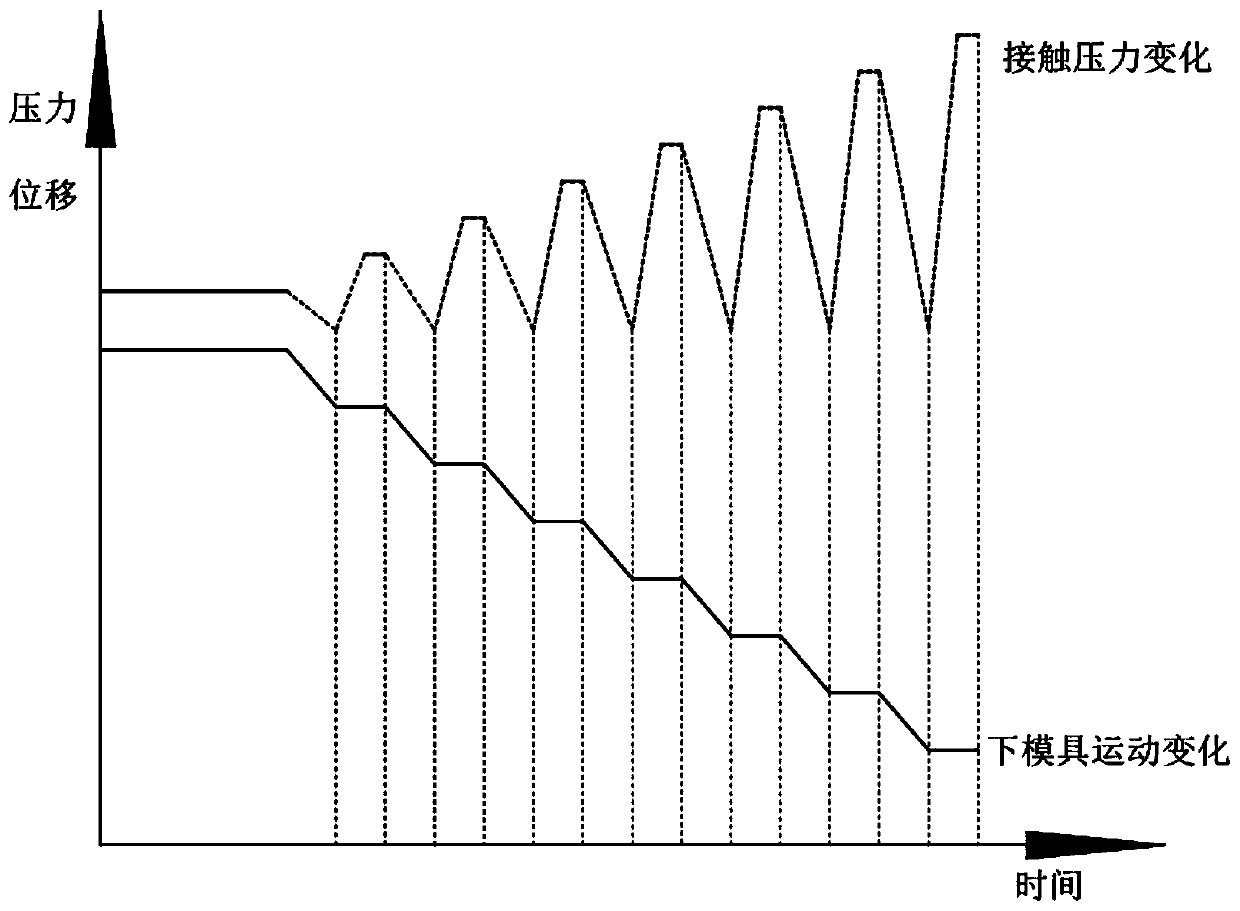

[0035] S1. The lower hydraulic cylinder 6 places the lower workbench 2 at the top dead center a of the lower workbench 2 and keeps it still;

[0036] S2. The blank 11 to be stamped is placed between the upper mold 3 and the lower mold 4, and the upper hydraulic cylinder 5 drives the upper worktable 1 to drive the upper mold 3 to move downward, and the stamping process starts;

[0037] S3. When the upper mold 3 descends before closing with the lower mold 4, control the oil pressure of the lower hydraulic cylinder 6 to be lower than the peak oil pressure of the upper hydraulic cylinder 5, thereby ensuring that the upper workbench 1 When in contact wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com