A simple metal stranded wire branching device

A branching device and technology of twisted wire, applied in the field of metal twisted wire branching device, can solve problems such as inconvenient operation, long branching time, slow branching speed, etc., achieve fast and effective branching and collection, improve The effect of resource utilization and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

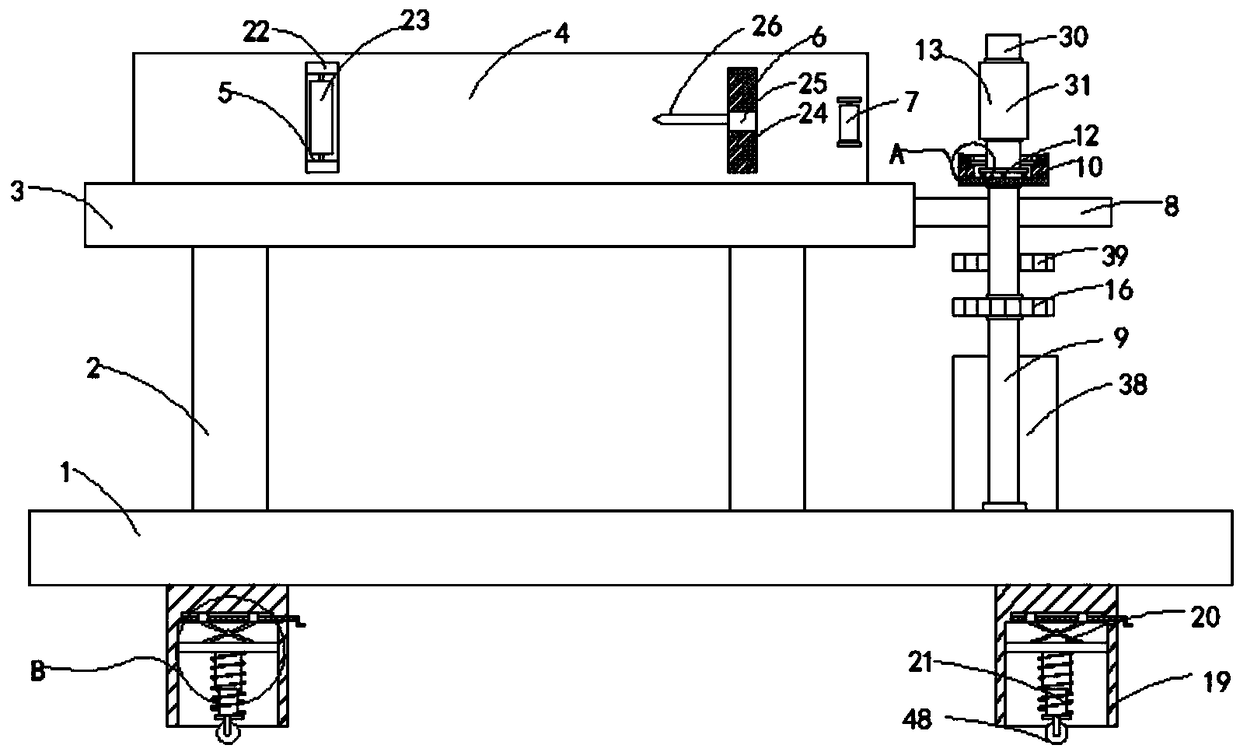

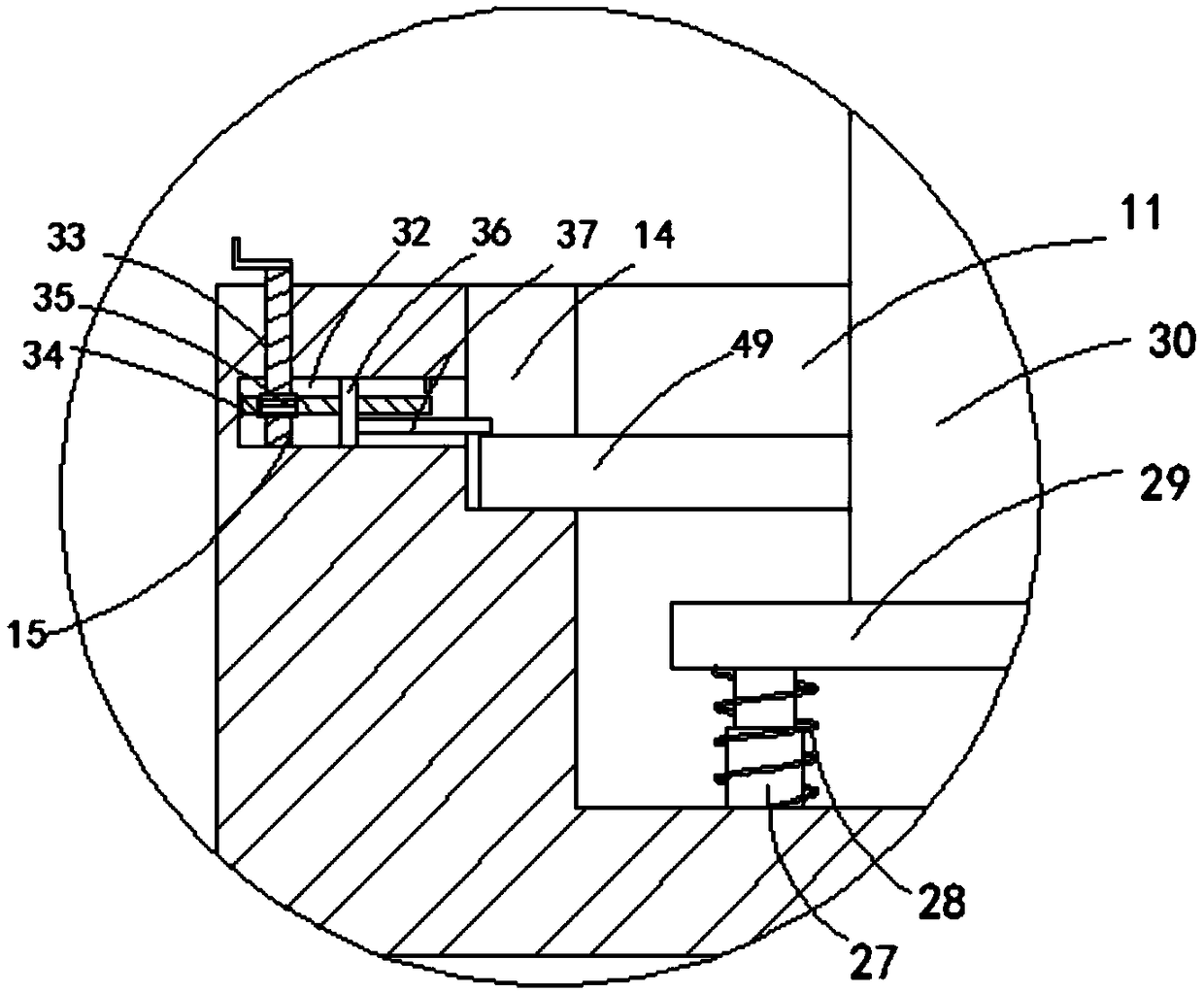

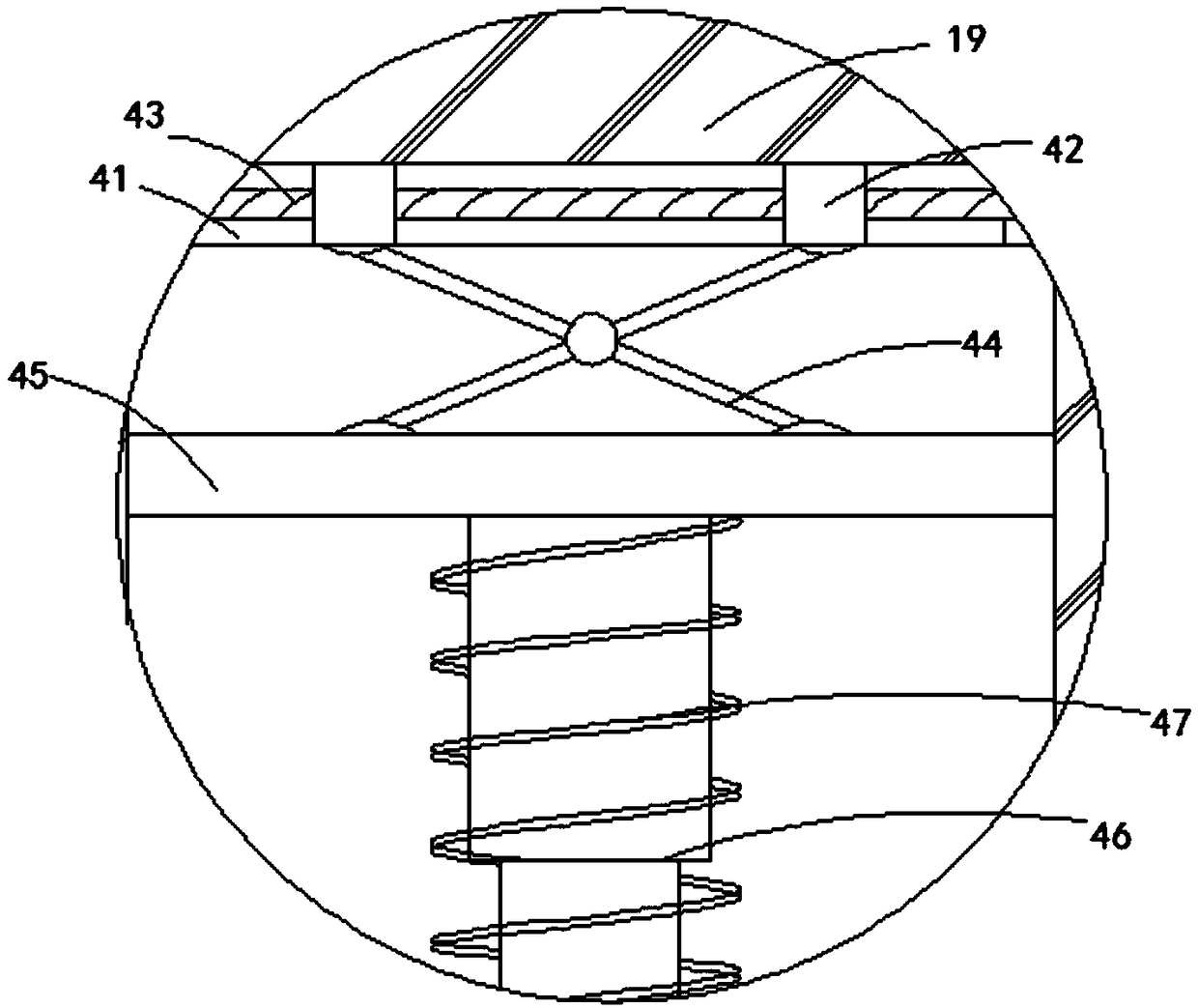

[0024] Such as Figure 1-5 As shown, a simple metal twisted wire branching device includes a base 1, a plurality of support columns 2 are arranged on the base 1, a console 3 is arranged on the support column 2, and two walking blocks are horizontally arranged on the console 3. Wire plate 4, a straightening mechanism 5 is provided between the two wiring boards 4, a wire dividing mechanism 6 is provided between the two wiring boards 4, and the wire dividing mechanism 6 is arranged on the wire routing plate 4 away from the straightening mechanism 5 On one end, guide rollers 7 are provided on the opposite side walls of the two wiring boards 4, and the guide rollers 7 are arranged on the end of the wiring board 4 close to the branching mechanism 6, and the side wall of the console 3 is close to the end of the guide rollers 7. Two horizontal plates 8 are connected to the top, and the two horizontal plates 8 are provided with a first through hole communicating up and down, and a rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com