Method and device for installing in-hole O-shaped seal ring

A technology of O-shaped sealing ring and mounting hole, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of difficult to ensure product quality, easy to scratch fingers, easy to dirty devices, etc., to facilitate disassembly and replacement of tooling, avoid The effect of direct finger contact and stable assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

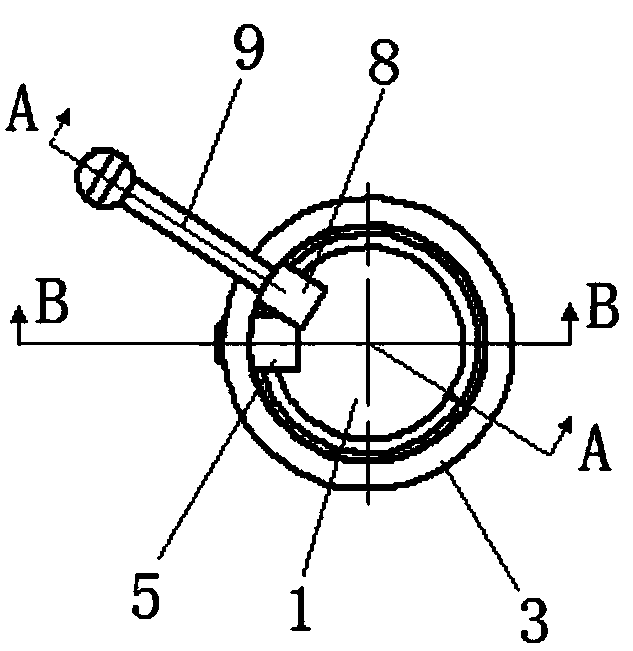

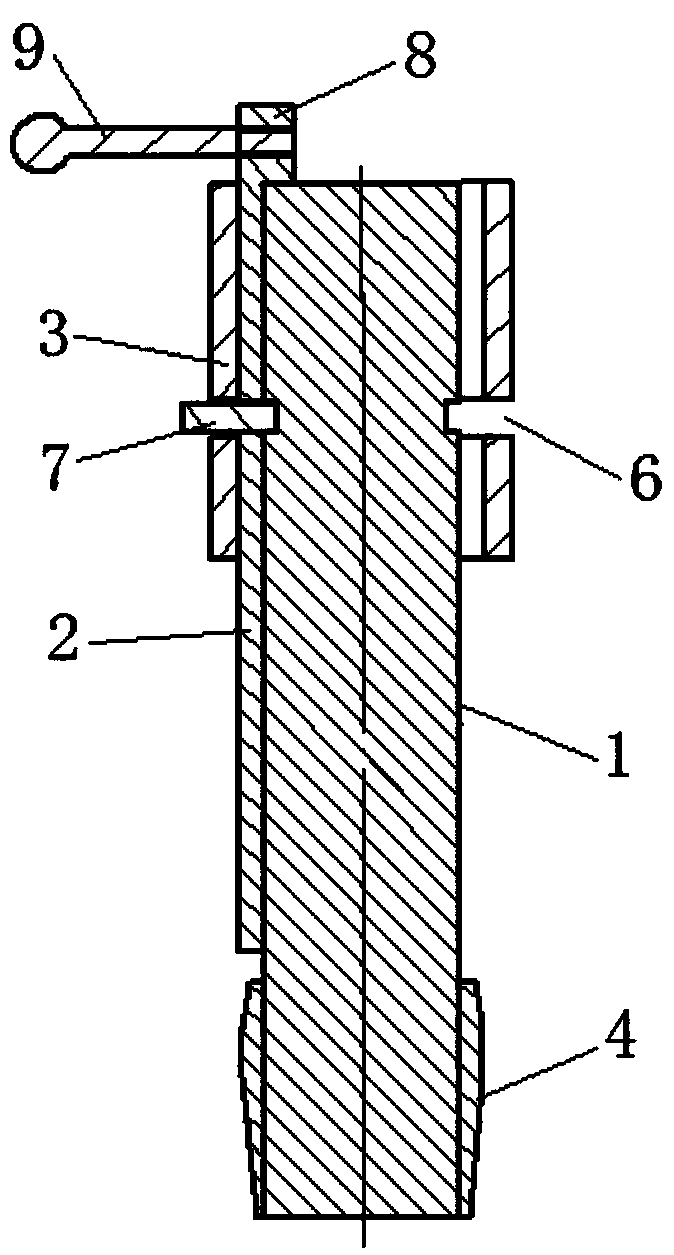

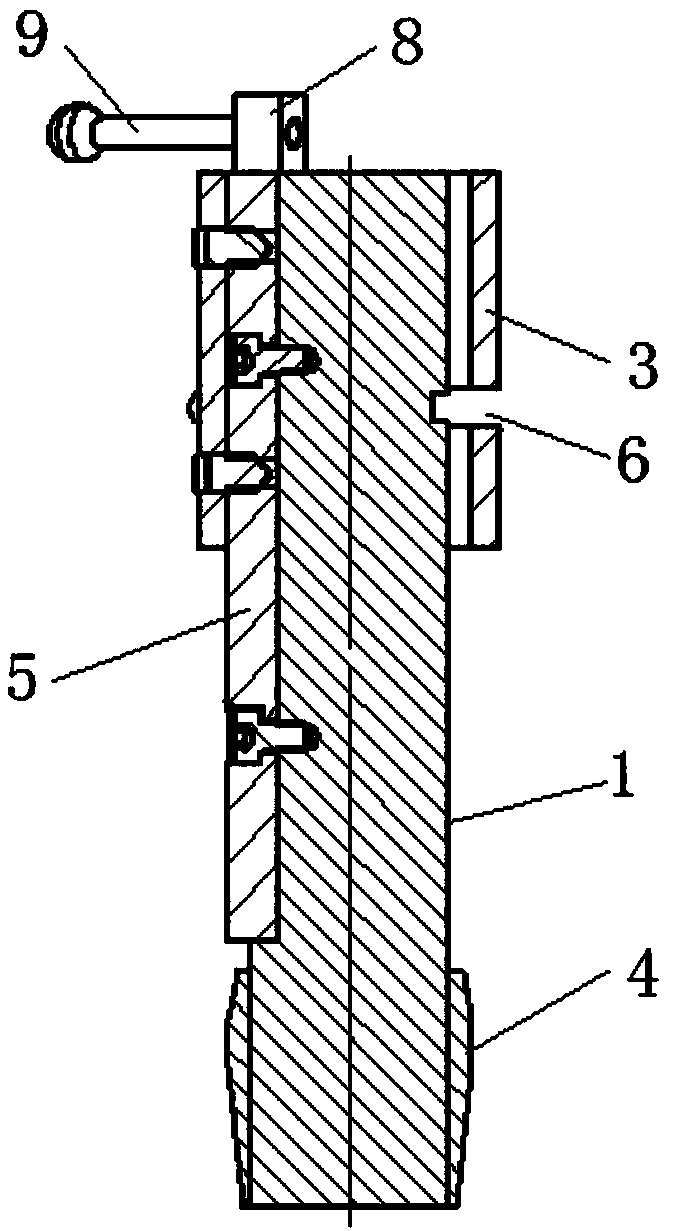

[0026] The specific embodiment of the present invention is like this: as Figure 1-6 As shown, a method for installing an O-ring in a hole includes the following steps: First, a positioning mandrel 1 is set to position the O-ring at its front end, and the positioning mandrel 1 is inserted into the installation hole Make the O-shaped seal ring correspond to the installation groove in the installation hole, insert the positioning mandrel 1 into the bottom of the injector hole, and the O-ring seal on the positioning mandrel 1 corresponds to the installation groove in the hole; then, in A shift fork 2 that can rotate around the cylindrical surface of the positioning mandrel 1 is inserted into the gap between the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com