Gear rack tail end approximate straight-line composite grabbing robot finger device

A robot finger, approximate straight line technology, applied in manipulators, chucks, manufacturing tools, etc., can solve the problem that the linear translation of the end finger segment cannot be realized, the dependence on the cooperative control programming of the robot arm is increased, and the adaptive envelope grasping cannot be realized. To achieve the effect of reducing programming requirements, low cost, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

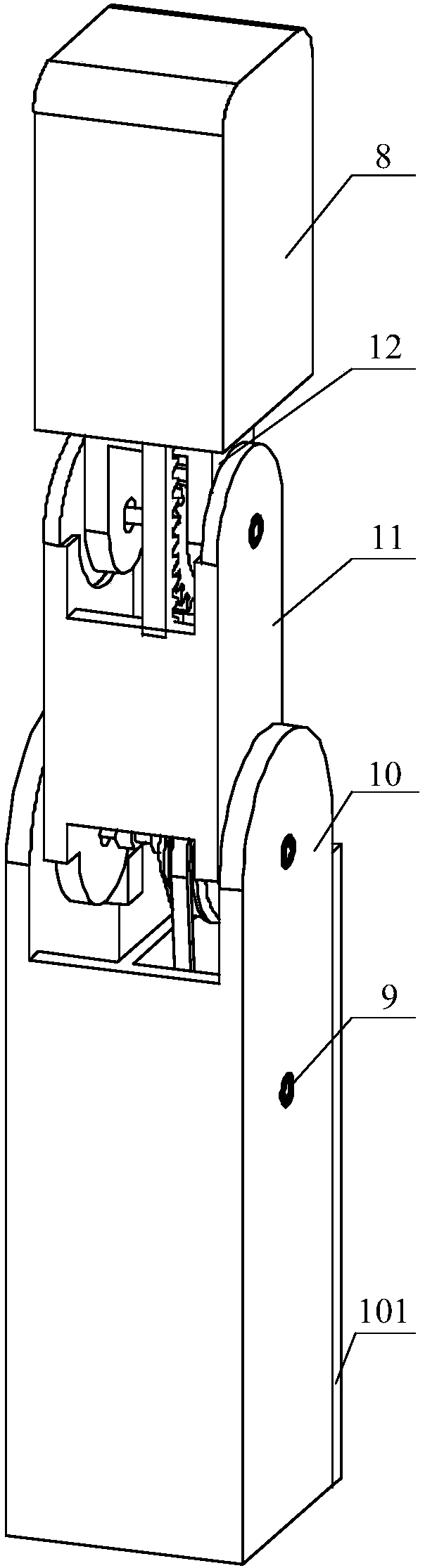

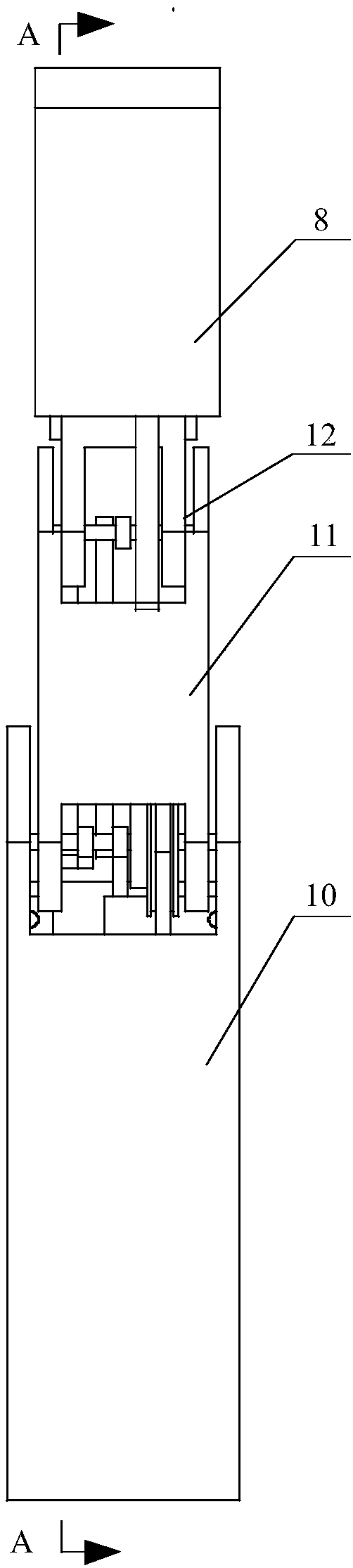

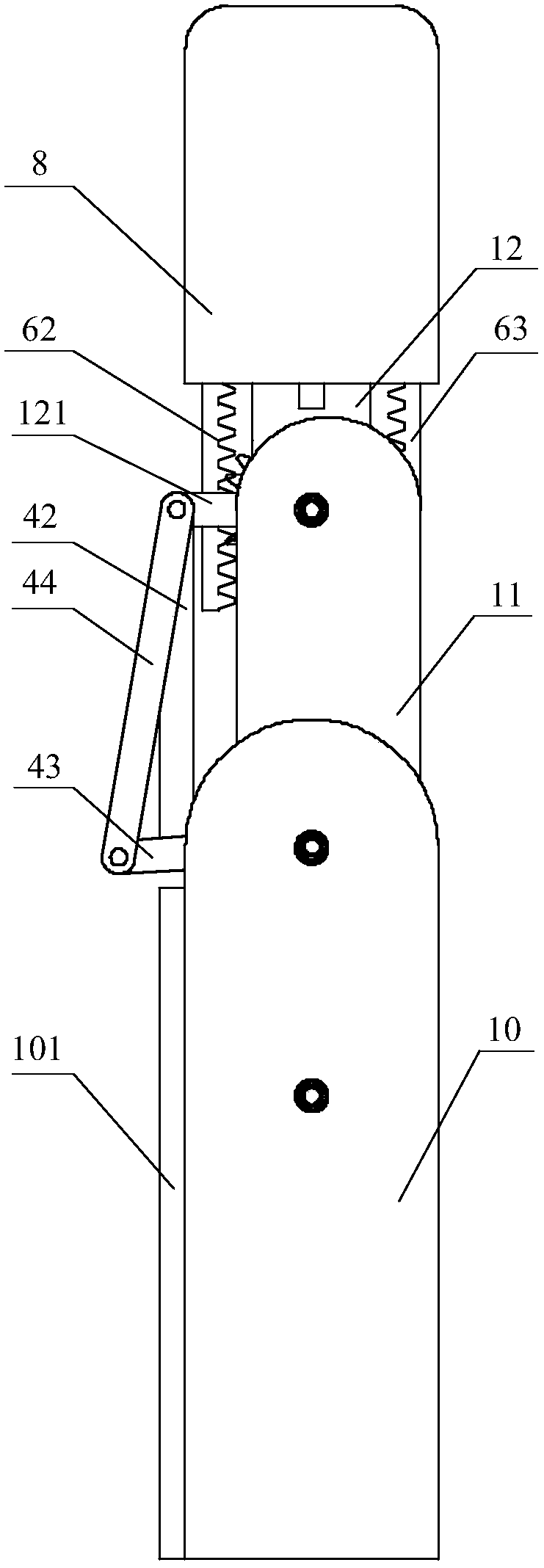

[0037] An embodiment of a rack and pinion end approximate straight line compound grasping robot finger device designed by the present invention, such as Figure 1 to Figure 7 As shown, it includes base 10, first finger segment 11, second finger segment 12, proximal joint shaft 31, distal joint shaft 32, motor 2, transmission mechanism, first connecting rod 41, second connecting rod 42, third Connecting rod 43, fourth connecting rod 44, second finger segment connecting rod 121, first rotating shaft 51, second rotating shaft 52, third rotating shaft 53, first spring 71, first limiting protrusion 73 and second limiting Protrusion 74; the proximal joint shaft 31 is sleeved in the base 10, the first finger segment 11 is sleeved on the proximal joint shaft 31, and the distal joint shaft 32 is sleeved i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com