Rim floating damping wheel for non-pneumatic tire

A technology for non-pneumatic tires and rims, which is applied in the field of non-pneumatic tire rim floating and vibration-damping wheels, can solve the problems of easy tire puncture and air leakage, unreplaceable tires, easy car overturning, etc., and achieves long service life and low manufacturing cost. , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

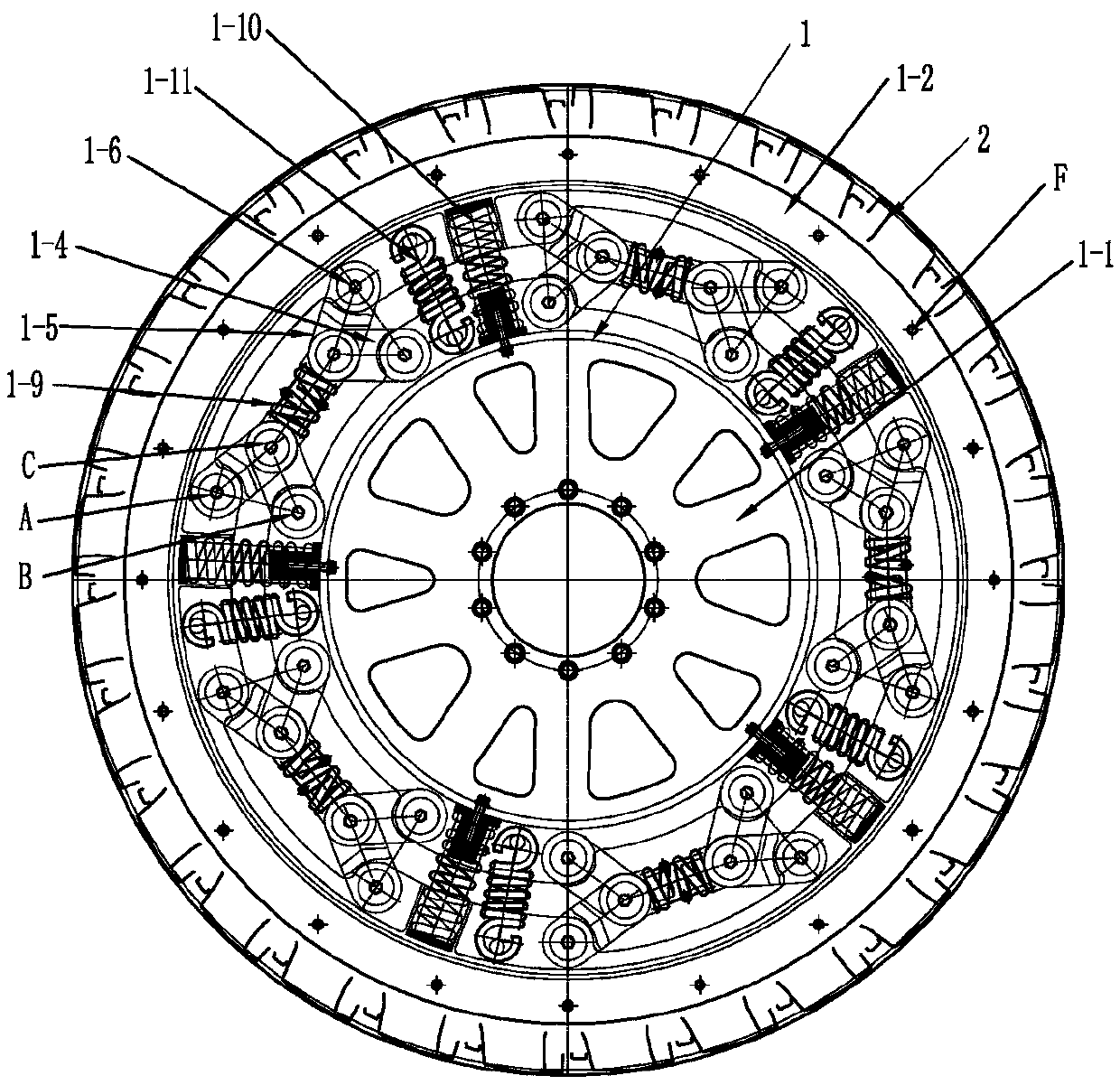

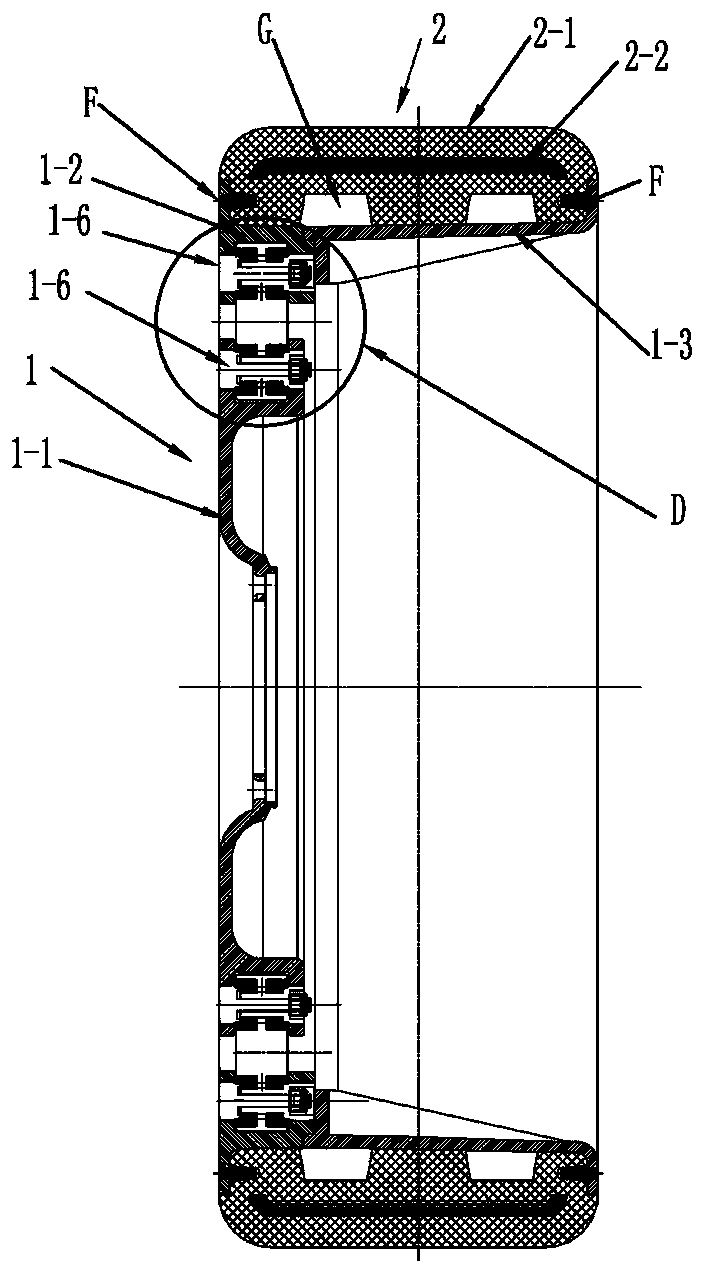

[0017] Such as Figure 1-Figure 3 As shown, the present invention is further described as follows: a non-pneumatic tire rim floating vibration-damping wheel, consisting of a floating vibration-damping rim 1 and a non-pneumatic tire 2, is characterized in that:

[0018] Floating damping rim 1, including inner spoke plate 1-1, outer spoke support ring 1-2, multiple lateral and radial composite support units uniformly distributed along the circumference are arranged between the outer spoke support ring and the inner spoke plate ;

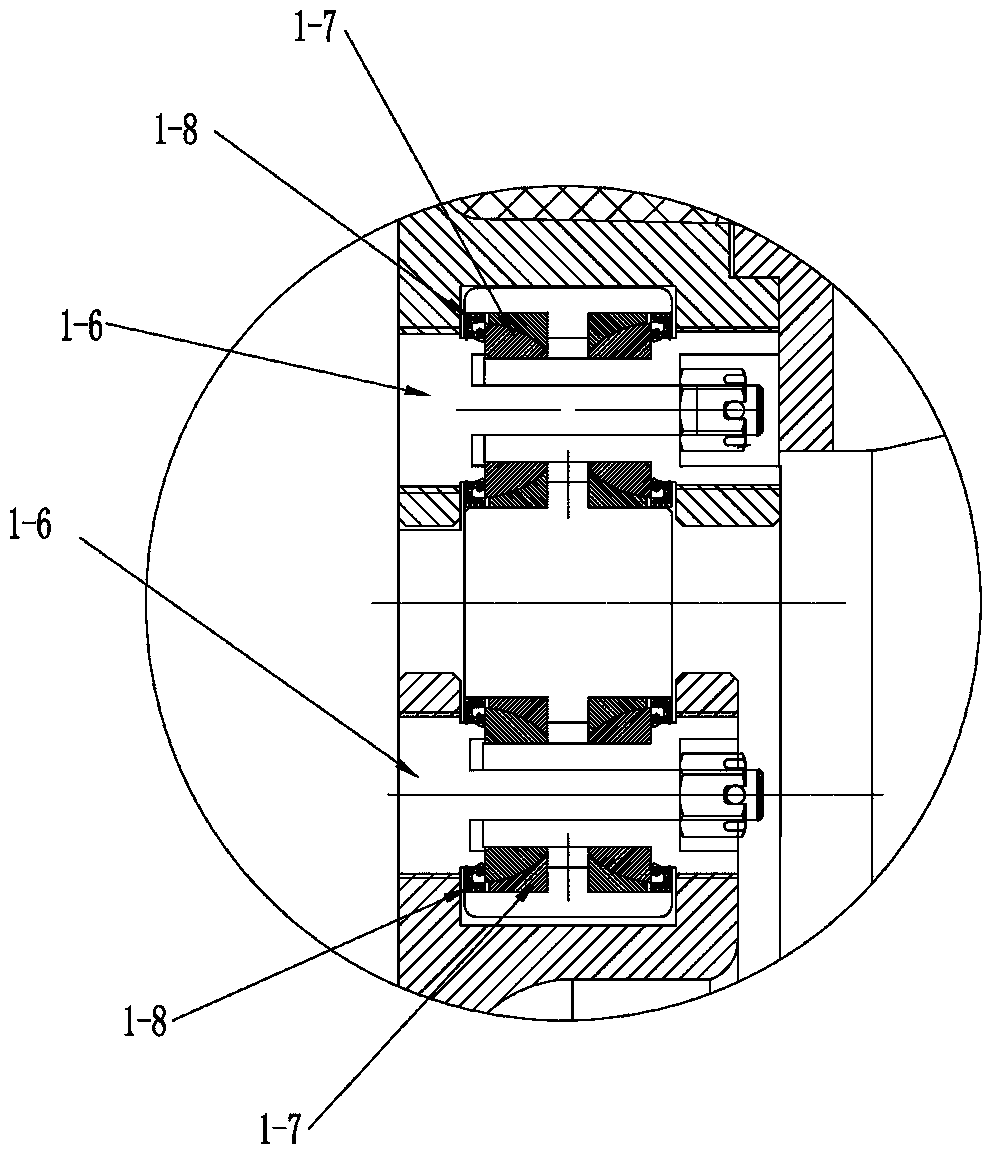

[0019] The structure of the lateral and radial composite support unit is: including radial elastic support and lateral buffer support;

[0020] Radial elastic support: one end of the radial compression spring 1-10 is supported in the outer circumferential concave groove of the inner spoke plate 1-1, and the other end of the radial compression spring 1-10 is supported in the circumferential concave groove of the outer spoke ring 1-2 In the groove, one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com