Power centralized EMU train water supply connection plate

A technology of power concentration and connection plate, applied in the direction of locomotives, etc., can solve the problems of installation space and self-weight limitations, and cannot be used in the environment where the power module is connected to the water circulation system. Ease of installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

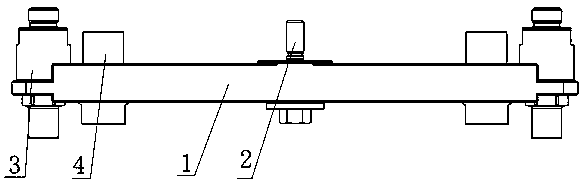

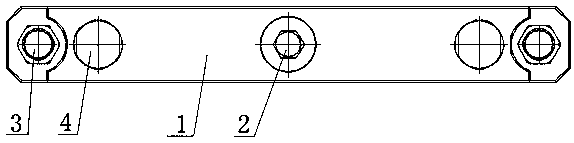

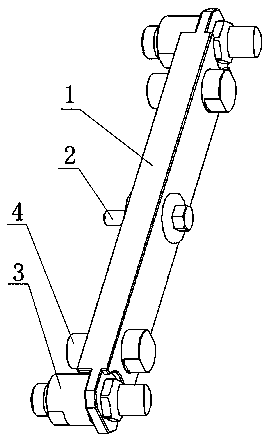

[0011] The power-concentrated EMU train water supply connecting plate includes a connecting plate body 1 with a length of 396 mm, a width of 53 mm, and a thickness of 27 mm. The center of the connecting plate body 1 is pierced with M12×1.75 fastening screws 2 from bottom to top. The connecting plate Both ends of the body 1 are processed with a 10mm thick concave platform, the upper surface of the concave platform is 12mm away from the upper surface of the connecting plate body 1, and the lower surface is 5mm away from the lower surface of the connecting plate body 1. The concave platform is vertically screwed with a total length of 91.3 mm along the water connection quick plug 3 symmetrically arranged in the center of the connecting plate body 1, the connection end of the water connection quick plug 3 ( figure 1 The upper end as shown) is 39mm away from the upper surface of the connecting plate body 1, the axis of the water connecting quick plug 3 is 22mm away from the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com