Forming method of high-precision satellite sensor beam

A molding method and sensor technology are applied in the field of molding satellite sensor beams, which can solve the problems of complicated molding and gluing assembly process, inability to realize RTM glue injection, etc., and achieve high strength, accurate angle, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and modifications without departing from the concept of the present invention.

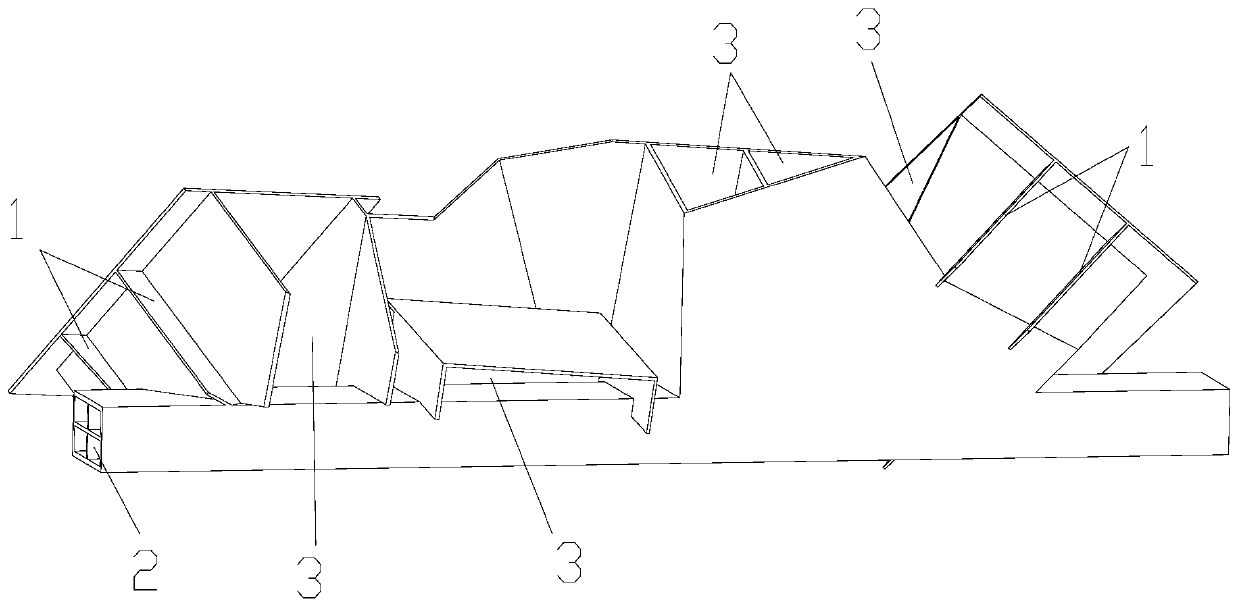

[0022] like Figure 1 ~ Figure 3 As shown, the forming method of the beam of the high-precision satellite sensor of the present invention includes:

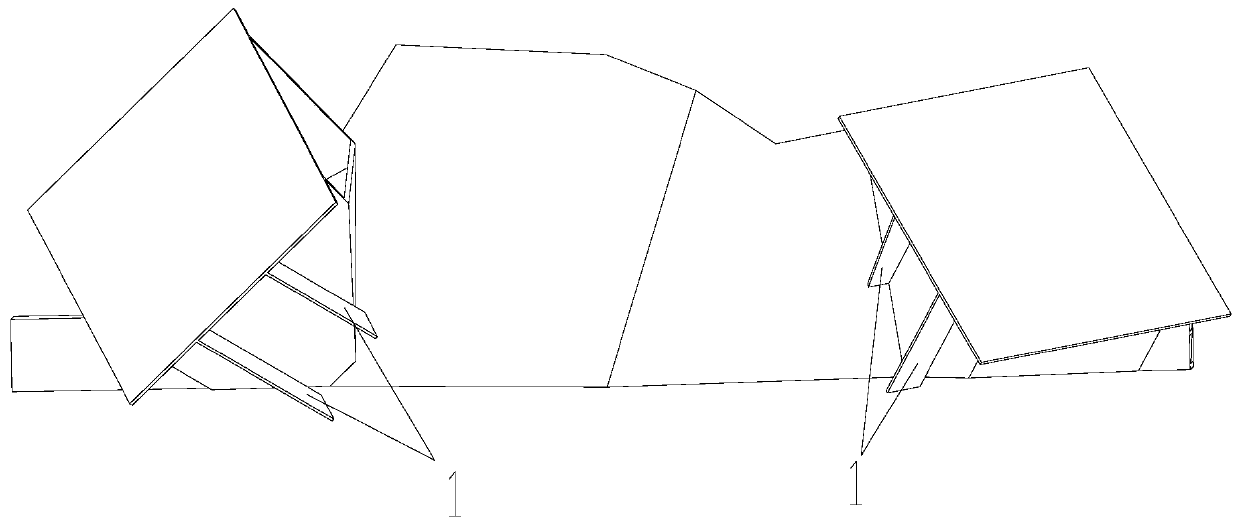

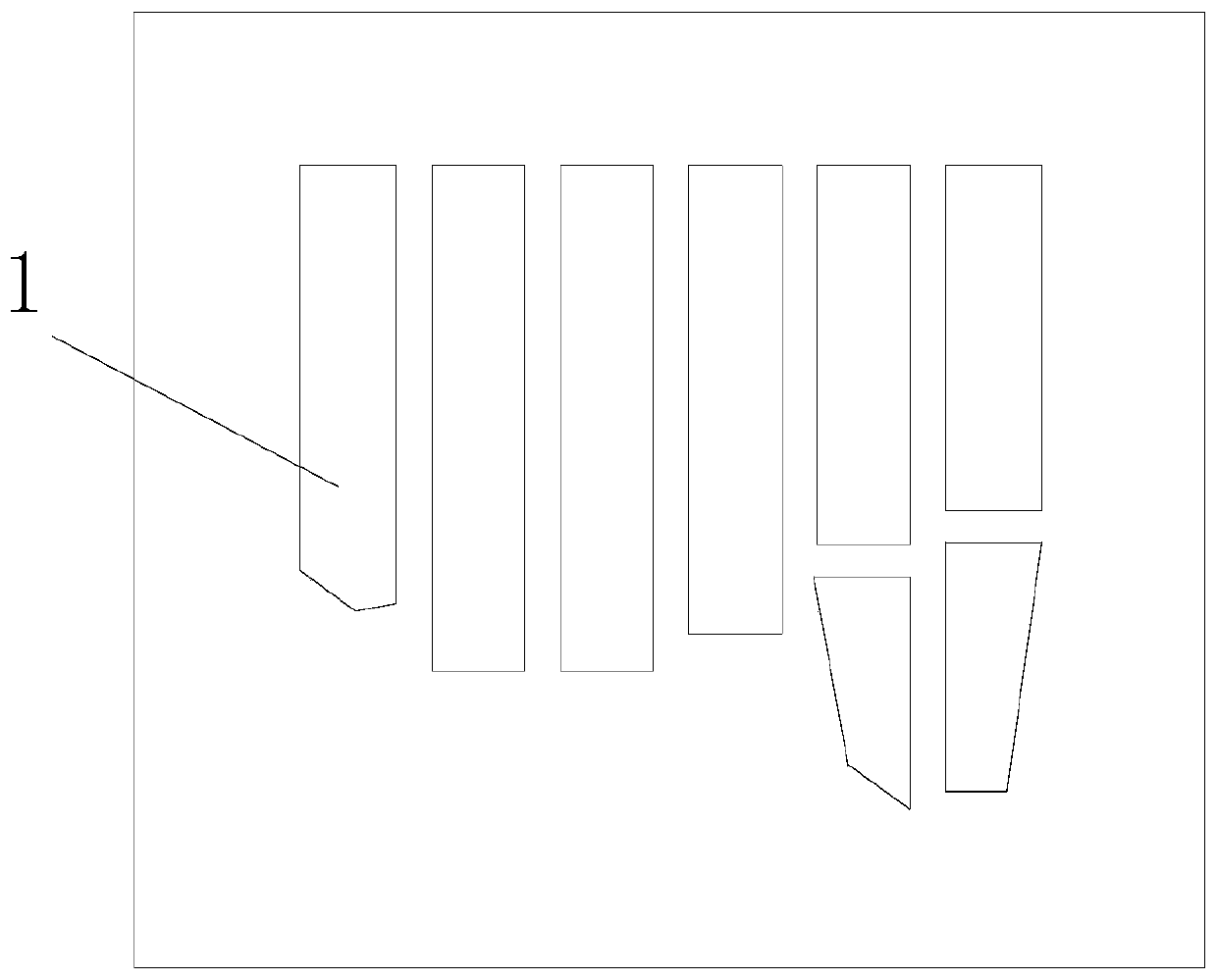

[0023] The first step, the preparation of pre-set stiffeners: such as image 3 As shown, the formed laminate is solidified by a press, and 8 ribs of different sizes are processed according to the product design requirements. The specific placement is as follows figure 1 , 2 Shown in 1.

[0024] The second step, the overall lay-up: install the beam and the head of Xingmin to lay a certain thickness on the soft mold cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com