A kind of magnesium-lithium alloy waveguide cold bending forming method

A technology of magnesium-lithium alloy and forming method, applied in the field of communication, can solve problems such as heavy weight, and achieve the effect of improving yield and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment provides a cold-bent formed magnesium-lithium alloy BJ100 magnesium-lithium alloy waveguide assembly and a manufacturing method thereof, including the following steps:

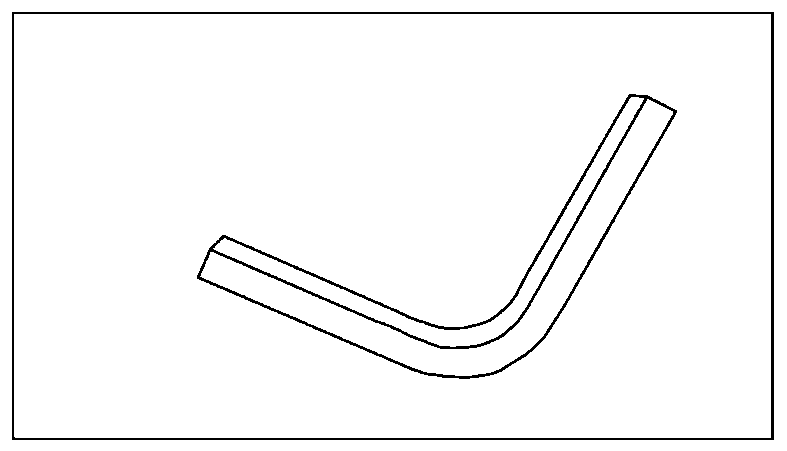

[0063] Step 1. Firstly, the selected BJ100 magnesium-lithium alloy waveguide to be cold bent, such as figure 1 As shown, the inner hole size measurement is performed. Its dimension on the E side (width) should be 22.86±0.046;

[0064] Step 2: On the basis of the above-mentioned E surface size of 22.86±0.046, subtract the value of 0.03 to select the inner hole thin steel strip, and apply the selected thin steel strip of different thickness to the cylinder oil plug to fill the inner hole of the BJ100 magnesium-lithium alloy waveguide;

[0065] Step 3. Put the BJ100 magnesium-lithium alloy waveguide filled with thin steel strips of different thicknesses on the E side and apply cylinder oil on the outer surface, and then put it into the elbow mold. Then insert the anti-wrinkle mold, push against ...

Embodiment 2

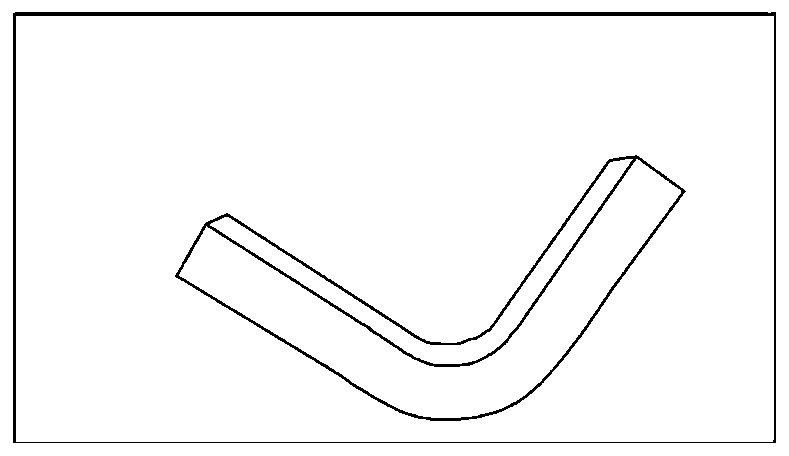

[0074] This embodiment provides a magnesium-lithium alloy BJ100 magnesium-lithium alloy waveguide assembly formed by cold bending. The manufacturing method is basically the same as that of Embodiment 1, with the only difference being cold bending on the H surface (thickness);

[0075] The cold-bent formed magnesium-lithium alloy BJ100 waveguide assembly provided in this embodiment is as follows figure 2 As shown, the inner hole size of the waveguide on the H surface (thickness) is 10.16±0.046; the width of the selected thin steel strip should be 10.16±0.04, minus 0.03; the selected thin steel strips of different thicknesses are coated with cylinder oil Fill the inner hole of the BJ100 magnesium-lithium alloy waveguide; since the width of the H side is 12.70 smaller than the width of the E side, the bending speed of this component is 26° / sec and the average bending speed is 8° / sec.

Embodiment 3

[0077] This embodiment provides a cold-bent formed magnesium-lithium alloy BJ120 waveguide assembly, and its manufacturing method is basically the same as that of the first embodiment. The difference is that due to the different models, the dimensions of the wide side (E) and the narrow side (H) have changed.

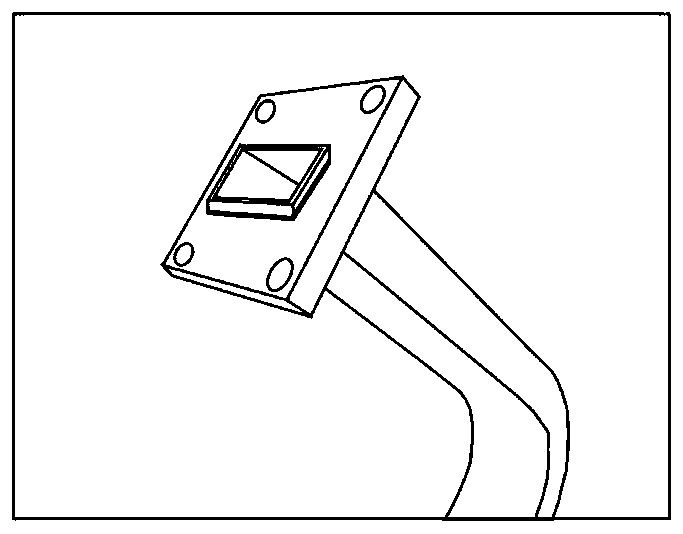

[0078] The cold-bent formed magnesium-lithium alloy BJ120 waveguide assembly provided in this embodiment is as image 3 As shown, the inner hole size of the waveguide on the E side (wide side) is 19.05±0.038; the width of the selected thin steel strip should be 19.05±0.038 minus 0.03, and the selected thin steel strips of different thicknesses will be coated The upper cylinder oil is superimposed and stuffed into the inner hole of the BJ120 magnesium-lithium alloy waveguide; since the width of the E-side of the BJ120 magnesium-lithium alloy waveguide is basically the same as that of the E-side of the BJ100 magnesium-lithium alloy waveguide, the parameters entered on the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com