Film roll locating device for surface film pasting of plastic product

A technology of positioning device and film roll, which is applied to the field of film roll positioning device for sticking film on the surface of plastic products, can solve the problems of inconvenient replacement, inability to adjust adaptively, and inability to carry out film sticking work, etc., and achieves convenient implementation, simple structure and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

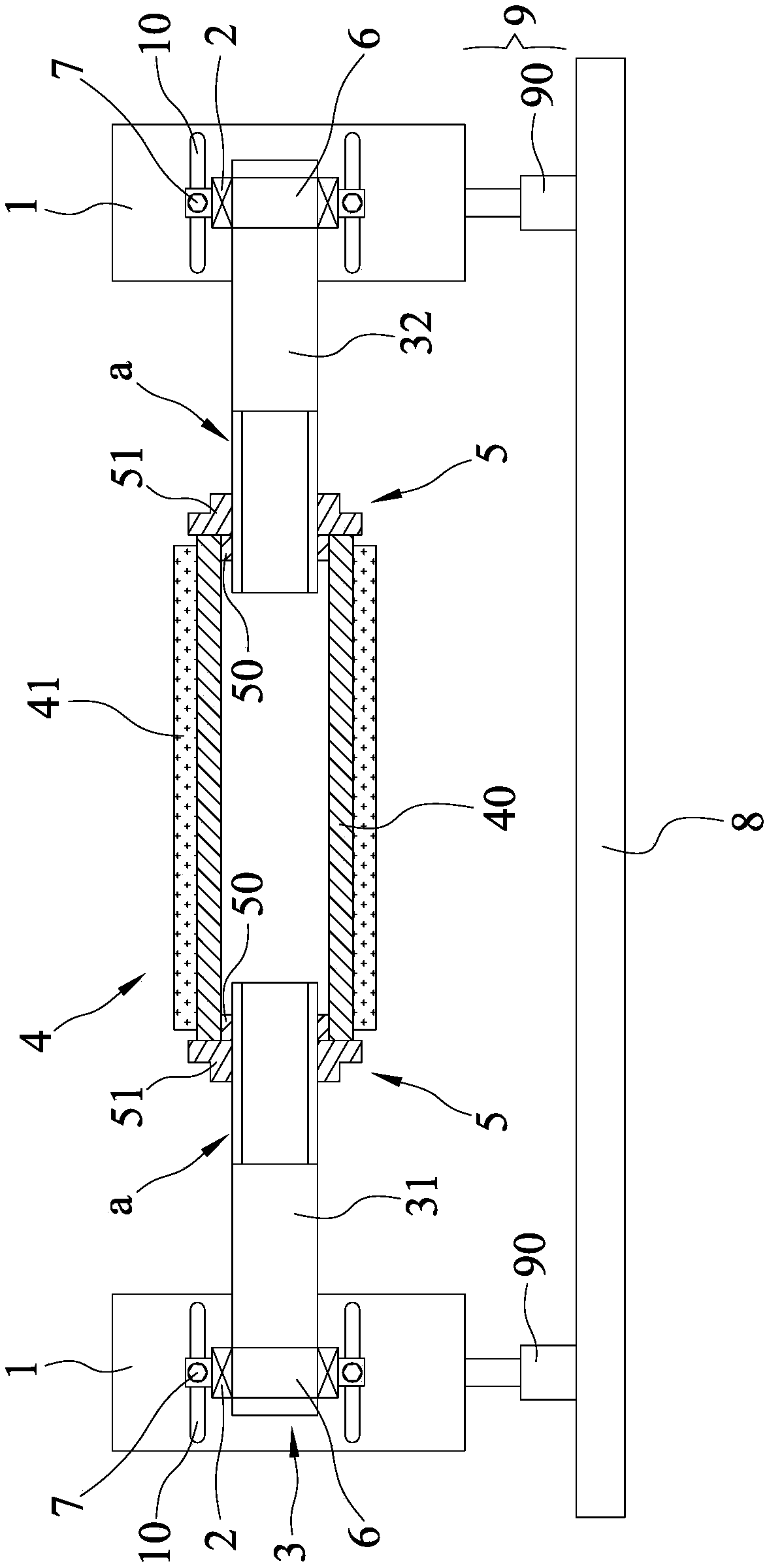

[0023] Such as figure 1 As shown, this example provides a film roll positioning device for plastic product surface film, which includes a positioning frame 1 located on both sides, a rotating shaft 3 that is arranged on the positioning frame 1 through a bearing 2 that rotates around its own axis direction, Wherein the rotating shaft 3 is disconnected from the middle to form a first rotating shaft body 31 and a second rotating shaft body 32, and the first rotating shaft body 31 and the second rotating shaft body 32 are arranged on the positioning frames 1 on both sides for moving adjustments that are relatively close or far away respectively. The two ends of the film roll 4 are sheathed on the inner ends of the first rotating shaft body 31 and the second rotating shaft body 32 respectively.

[0024] The positioning device also includes a positioning member 5 which is respectively movable on the first rotating shaft body 31 and the second rotating shaft body 32 and which can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com