Cable aluminum strip winding machine equipped with multifunctional bracket structure

A support structure and multi-functional technology, which is applied in the direction of thin material handling, conveying filamentous materials, transportation and packaging, etc., can solve the problems of laborious, many cables, and consume a lot of physical strength of the staff, so as to prevent slipping and entanglement The effect of high efficiency and high winding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to clearly illustrate the technical features of the present solution, the present invention will be described in detail below through specific implementation methods and in conjunction with the accompanying drawings. It should be noted that components illustrated in the figures are not necessarily drawn to scale. Descriptions of well-known components and techniques are omitted herein to avoid unnecessarily limiting the present invention.

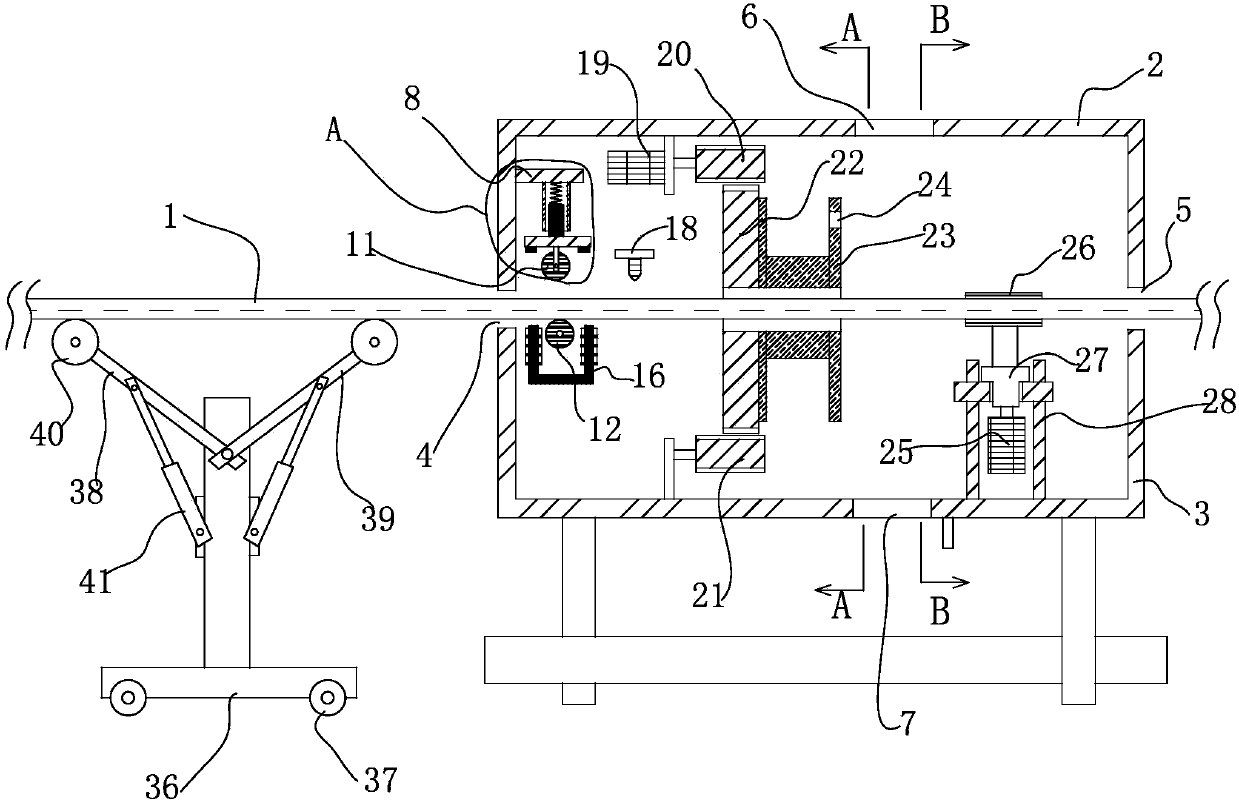

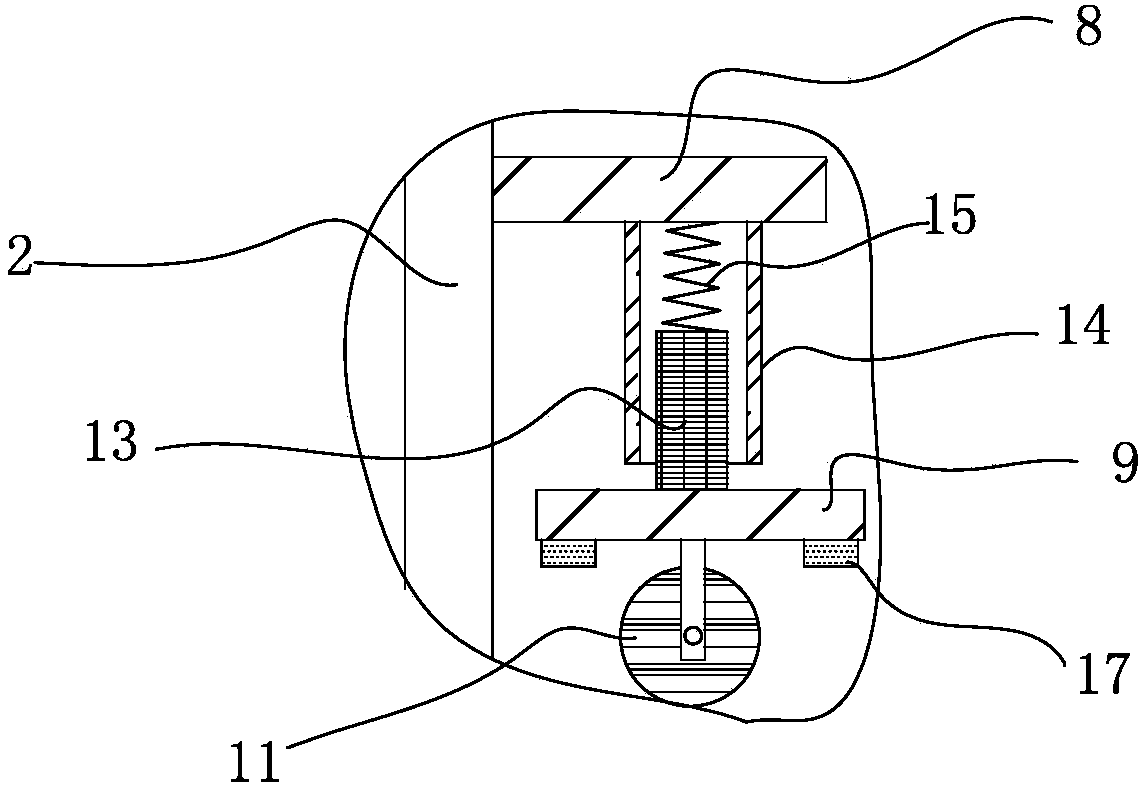

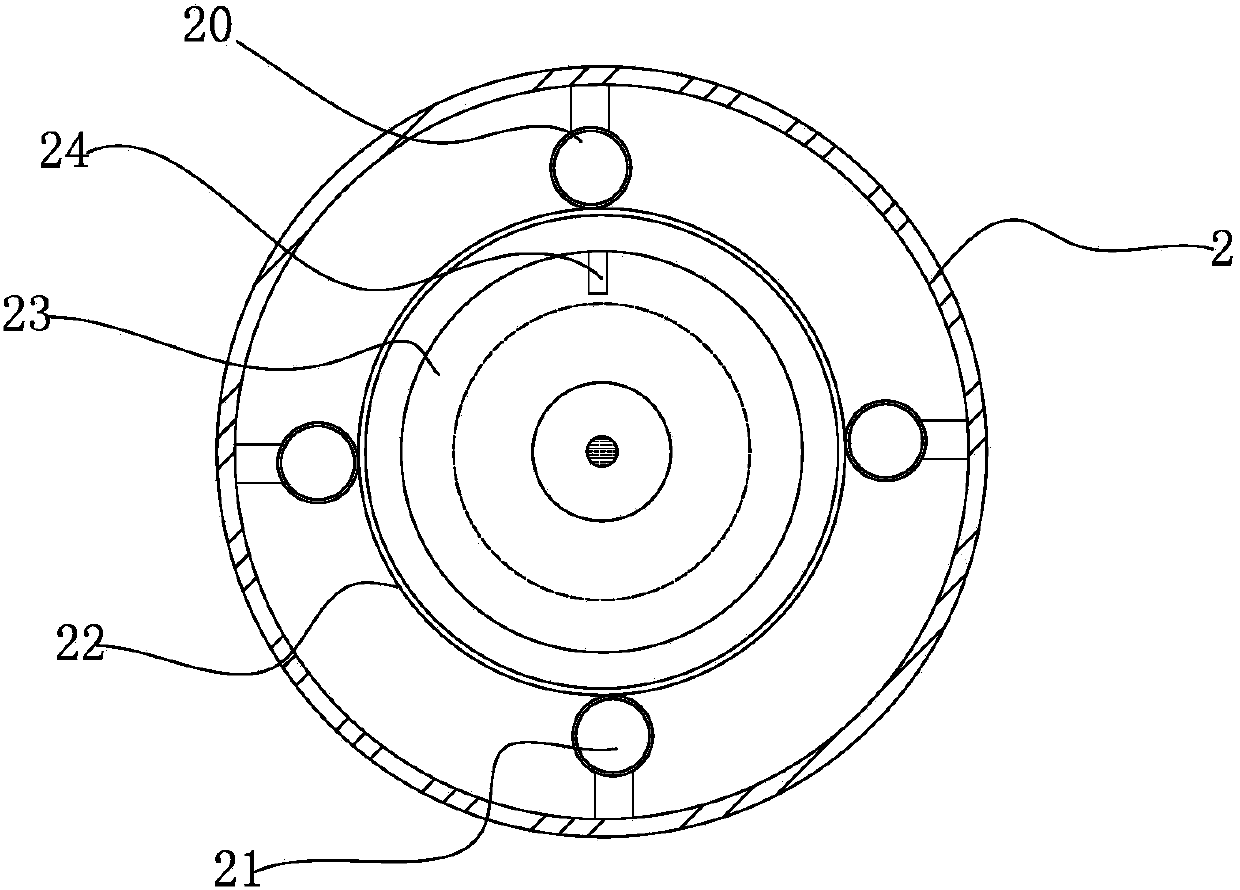

[0021] Such as Figure 1 to Figure 4 As shown, a cable aluminum strip winding machine with a multifunctional support structure includes a casing, a transmission system, a winding system, a pressing system and a control system, and the casing is used to install other functional components. The casing includes an upper casing 2 and a lower casing 3, and the edges of the upper casing 2 and the lower casing 3 are connected by bolts to realize the detachable assembly between the upper casing 2 and the lower casing 3. The connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com