A composite sealing structure of brush type and grate teeth

A comb-tooth and brush-type technology, which is applied in the field of brush-tooth and comb-tooth composite sealing structures, can solve the problems of difficult replacement, damaged seals, and easy breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

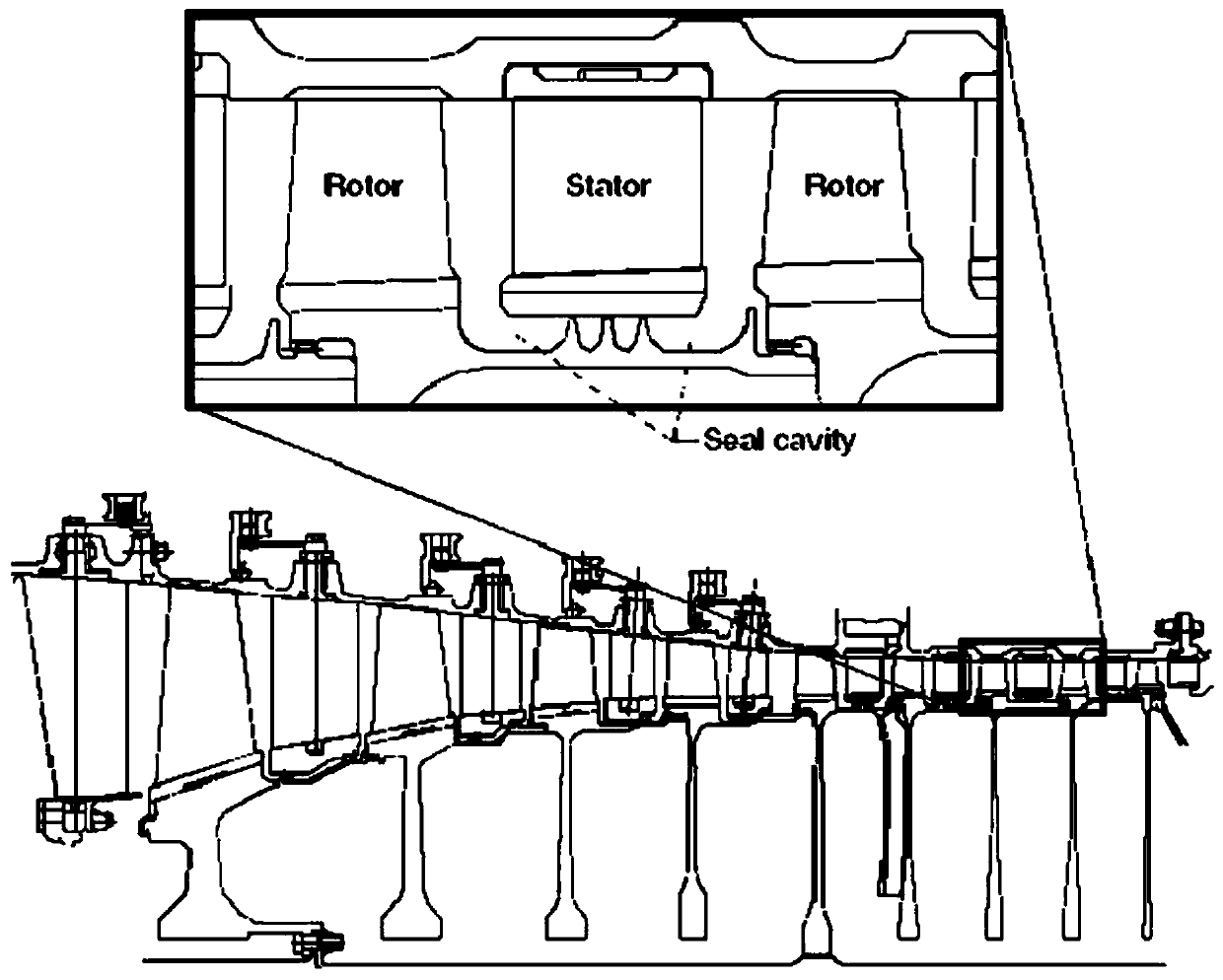

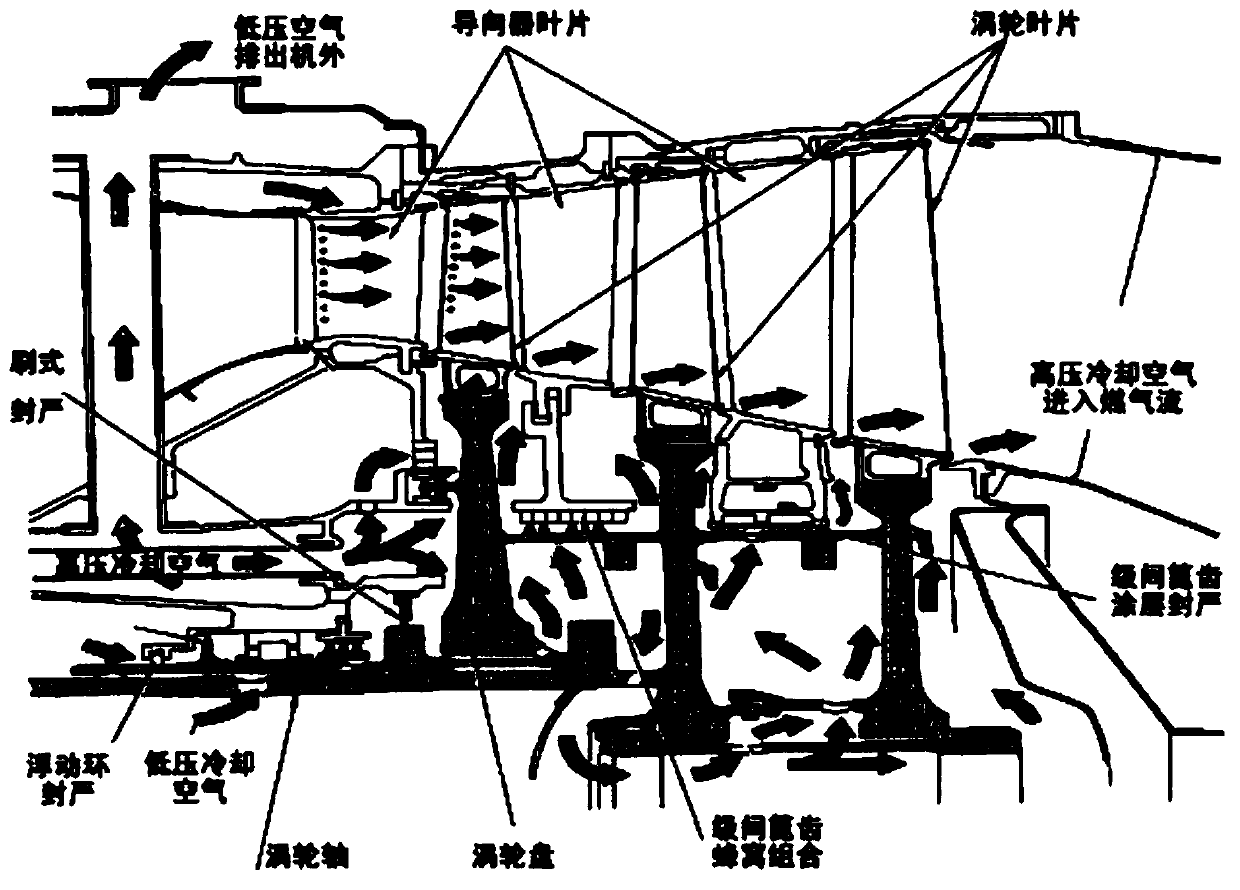

[0023] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

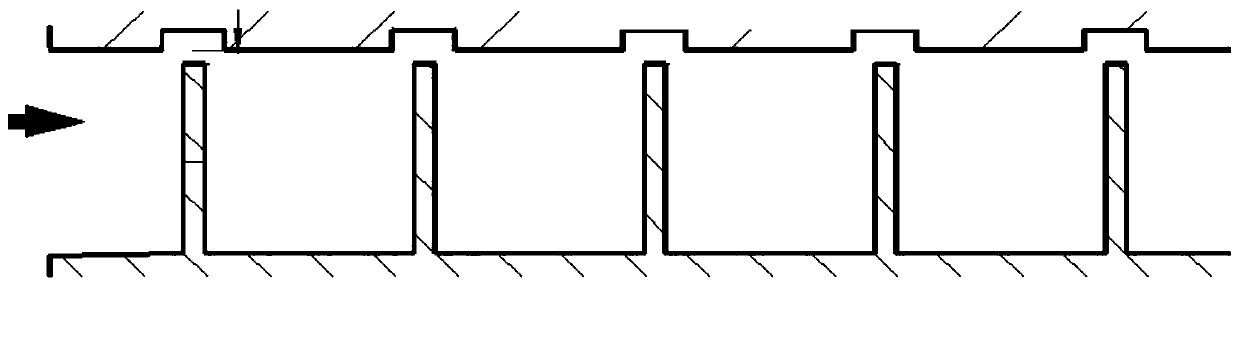

[0024] A composite sealing structure of brush type and grate teeth according to the present invention comprises a rotating shaft 1, a sealing bush 2 is provided on the outer coaxial sleeve of the rotating shaft 1, and a plurality of axially arranged annular sealing grate teeth are arranged on the rotating shaft 1 3. It is characterized in that: the inner surface of the sealing bush 2 is provided with an annular groove 4 corresponding to the sealing grate 3, the annular groove 4 is a smooth arc groove, and the tooth root of the annular sealing grate 3 is fixed on the rotating shaft 1, a protrusion 31 is formed in the middle of the outer peripheral surface of the tooth tip, the protrusion 31 is a smooth arc-shaped protrusion, and the curvature of the protrusion 31 is greater than the curvature of the annular groove 4, and the protrusion 31 extends...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap