Cylinder housing pump pressure tooling

A shell and cylinder technology, which is applied in the field of cylinder shell pump pressure tooling, can solve the problems of large pump pressure tooling and difficulty in applying the pressure test of the cylinder shell, so as to reduce the pressure test requirements and reduce the impact The size of the pressure and the effect of reducing the force-bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

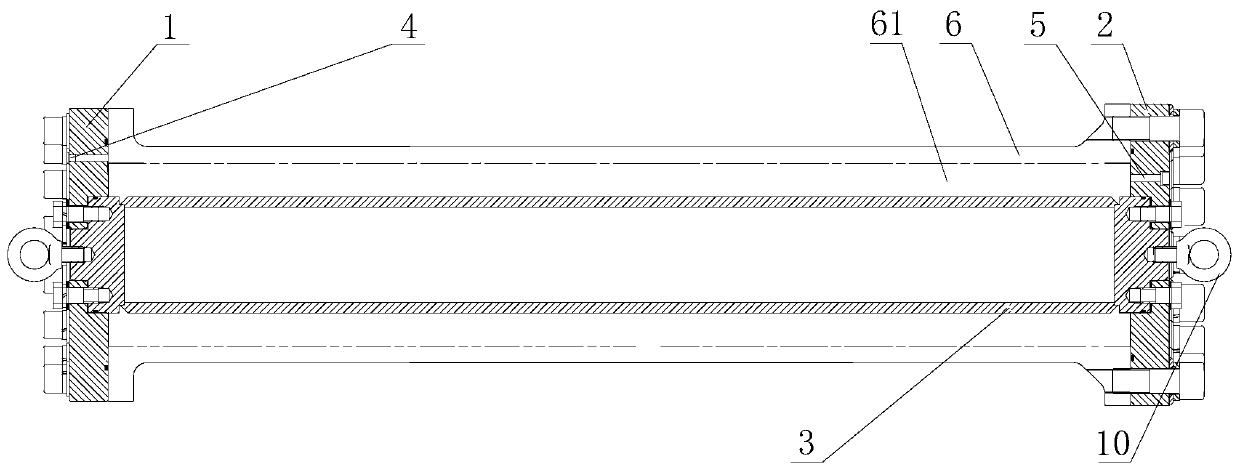

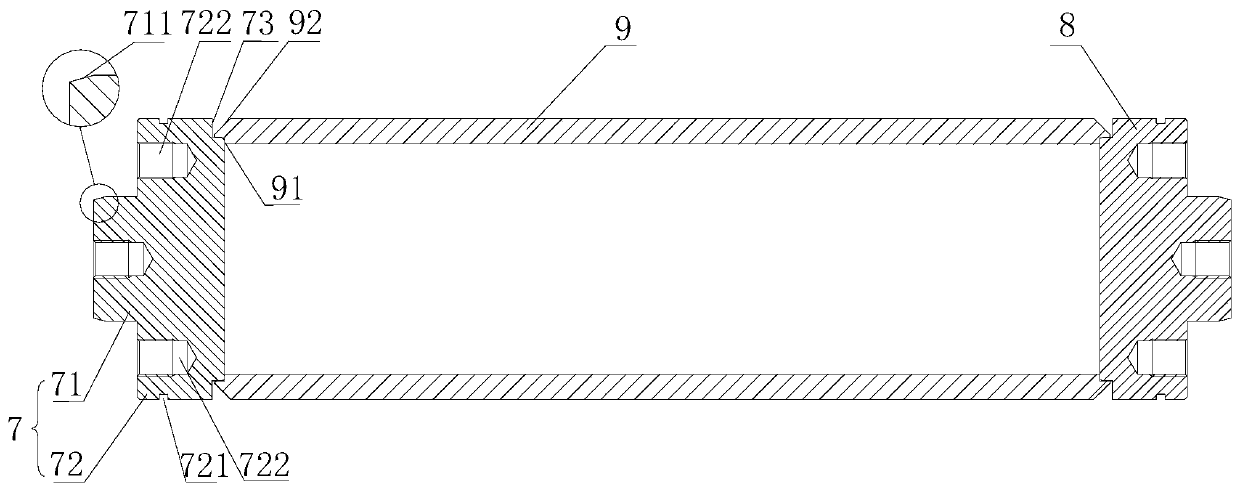

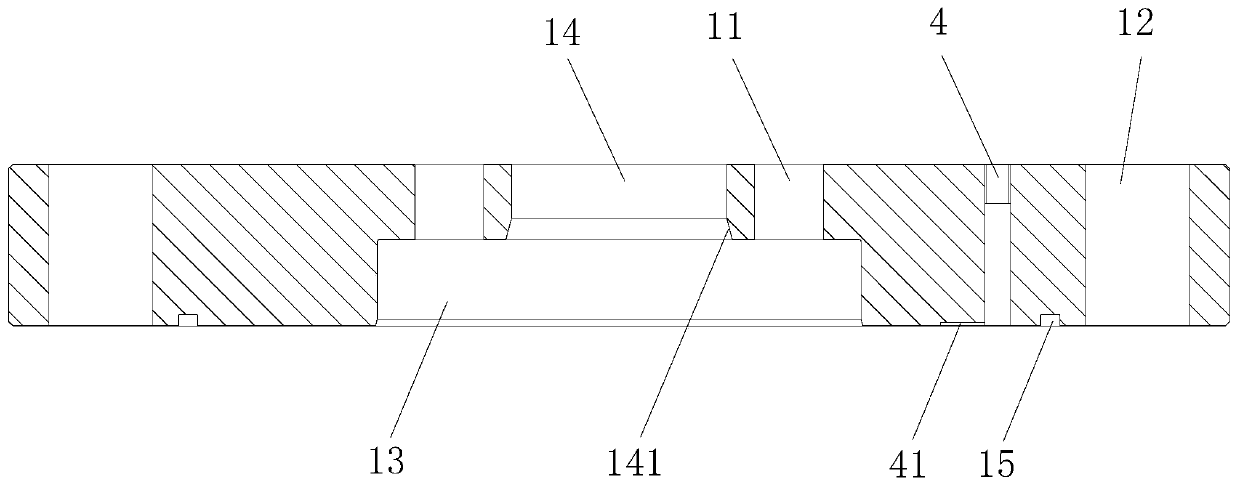

[0027] figure 1 It is a structural schematic diagram of the cylinder shell pumping tooling provided by the embodiment of the present invention, see figure 1 , the cylinder shell pumping tooling includes: a front end cover 1, a rear end cover 2 and a cylindrical main body structure 3, the front end cover 1 is provided with an exhaust hole 4 and a matching screw plug (not shown in the figure) , the rear end cover 2 is provided with an oil injection hole 5; the two ends of the cylindrical main structure 3 are arranged in parallel, the front end cover 1 and the rear end cover 2 are respectively fixed on the two ends of the cylindrical main structure 3, and the front end cover 1 and the rear At least one of the end caps 2 is detachably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com