Gearbox for single-screw extruder

A single-screw extruder, gear box technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the difficulty of manufacturing, processing and heat treatment, increase maintenance cost and labor intensity, and low use efficiency, etc. problems, to achieve the effect of improving stability, convenient processing and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

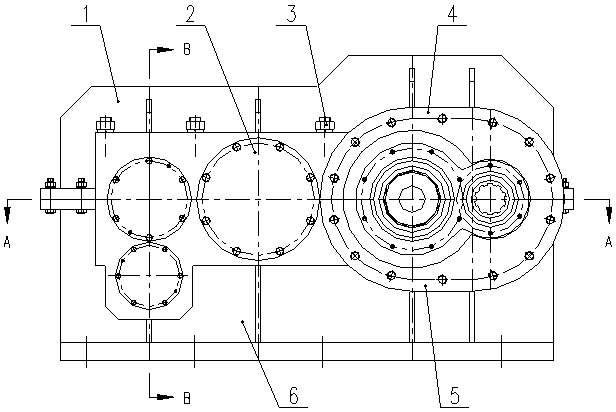

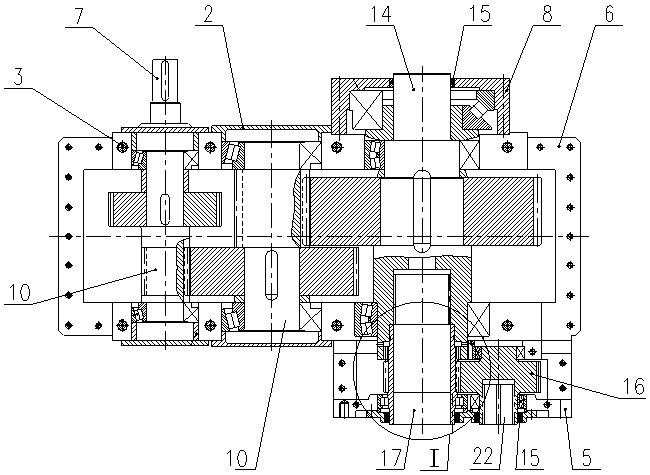

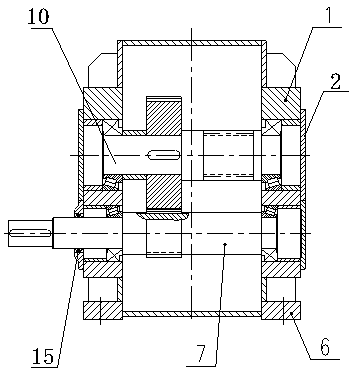

[0022] The accompanying drawings non-limitatively disclose the appearance and internal structure of a specific embodiment involved in the present invention, and the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Depend on Figure 1~3 It can be seen that it includes a box body, an input gear shaft 7 parallel to each other, a two-stage intermediate reduction gear shaft 10, and a hollow output shaft 14, wherein the box body includes an upper box body 1 and a lower box body 6, and the input gear shaft 7 passing through the box body and the hollow output shaft 14 are provided with a sealing device 15, the power output end of the hollow output shaft 14 is provided with (gear sleeve 17 and) speed ratio gear 16, and the other end is a thrust seat 8. , the corresponding box body is provided with an end cover 2.

[0024] In this embodiment: the power output end of the hollow output shaft 14 is equipped with a gear sleeve 17, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap