Sleeve oiling device

A technology of oil injection device and sleeve, which is applied in the direction of lubricating oil input, lubricating oil control valve, lubricating parts, etc. Uniformity and other problems, to achieve the effect of easy production, fast oil injection, and constant oil volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of the present invention, the present invention will be described in detail below in conjunction with the preferred embodiments of the present invention given in the accompanying drawings.

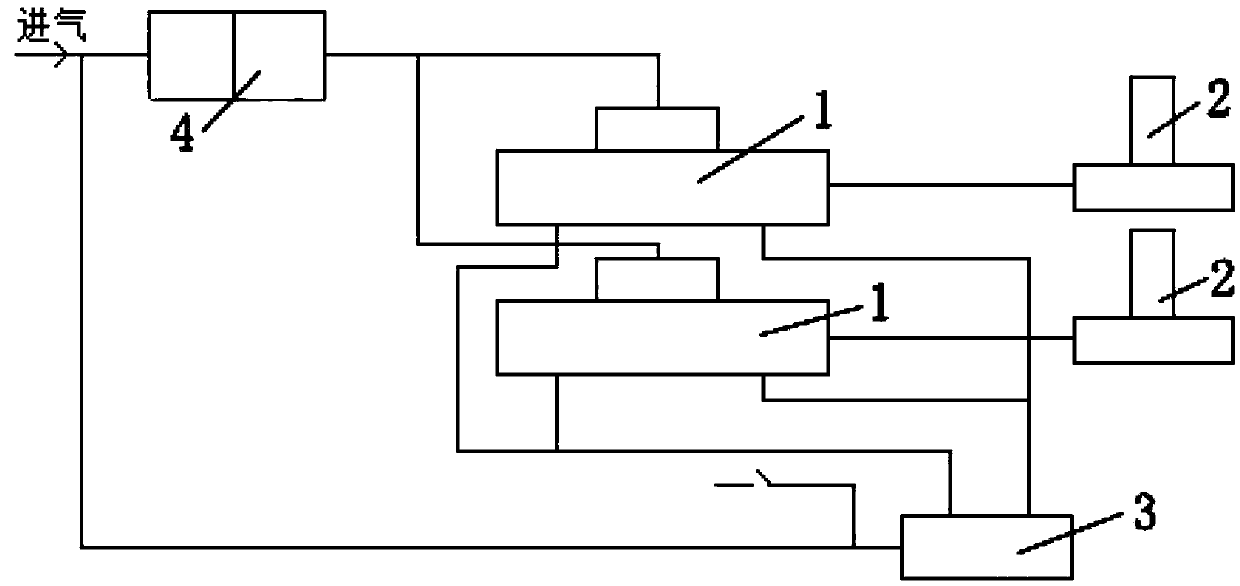

[0019] Such as figure 1 As shown, a sleeve oiling device according to an embodiment of the present invention, the principle structure of the device includes a grease quantitative valve, a grease nozzle, a solenoid valve and a pneumatic oiler, and the external air source is the solenoid valve, the pneumatic oiling Air is supplied to the device and the pedal, and the external oil storage device supplies lubricating grease to the pneumatic lubricator, and the lubricating grease output from the pneumatic lubricator to the lubricating nozzle is regulated through the grease quantitative valve. The electromagnetic valve controls the opening and closing action of the grease quantitative valve.

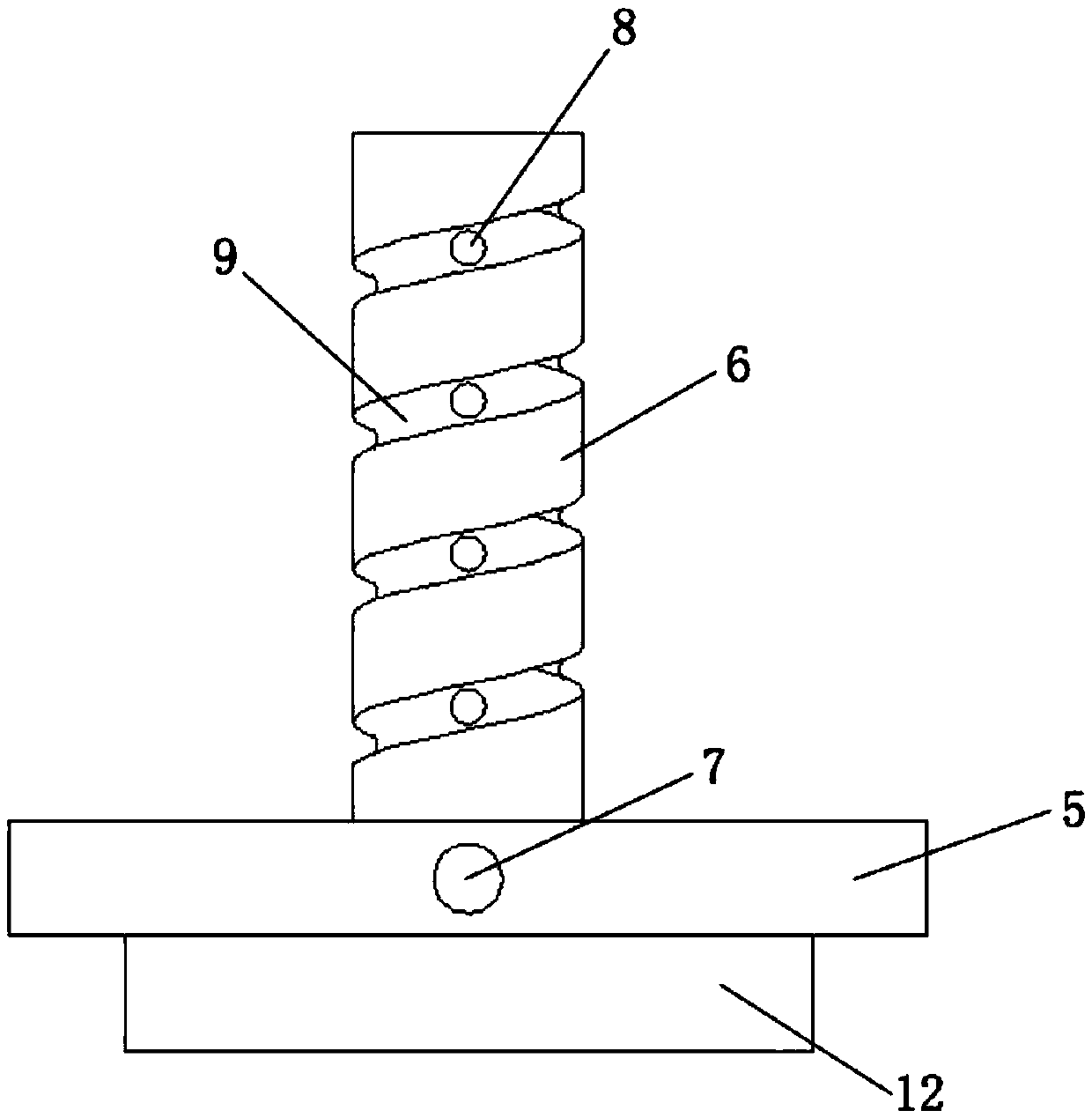

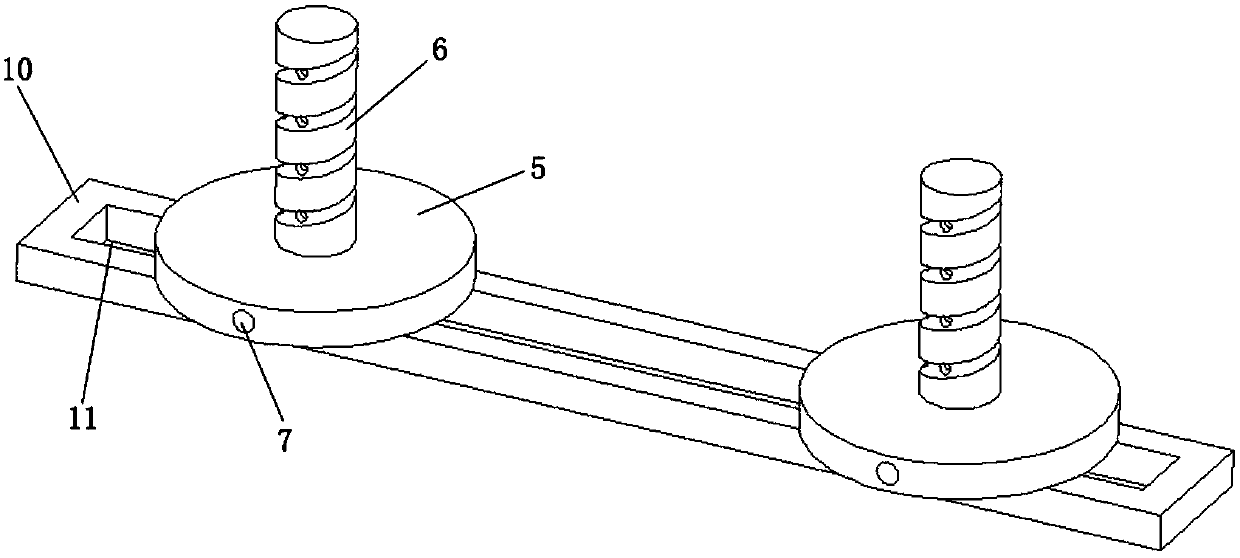

[0020] The device includes gas circuit structure and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com