Embedded down lamp general structure and embedded assembled lamp

A general structure, built-in technology, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, lighting devices, etc. Save the cost of purchasing lamps and apply flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

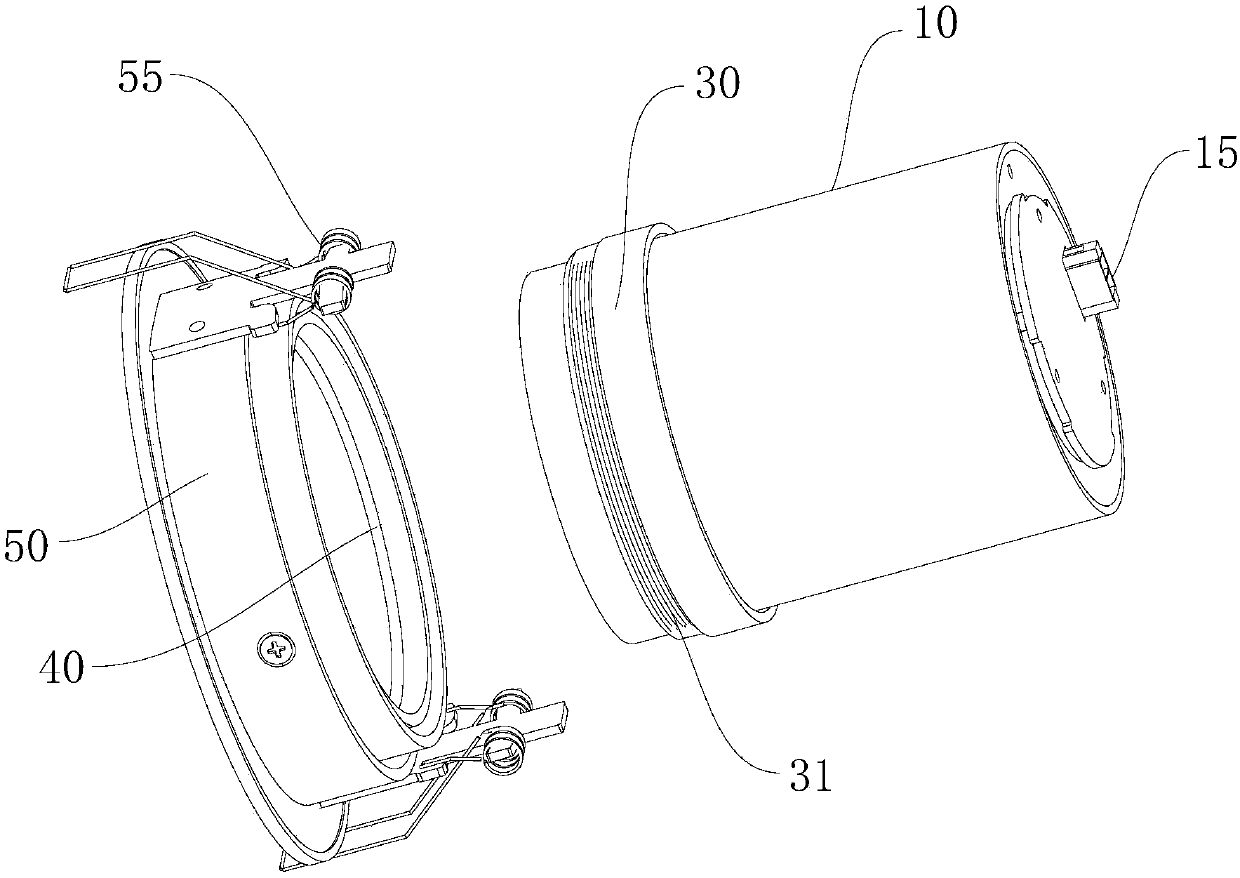

[0047] Please refer to Figure 1 to Figure 4 , this embodiment provides a general structure of a built-in downlight, including:

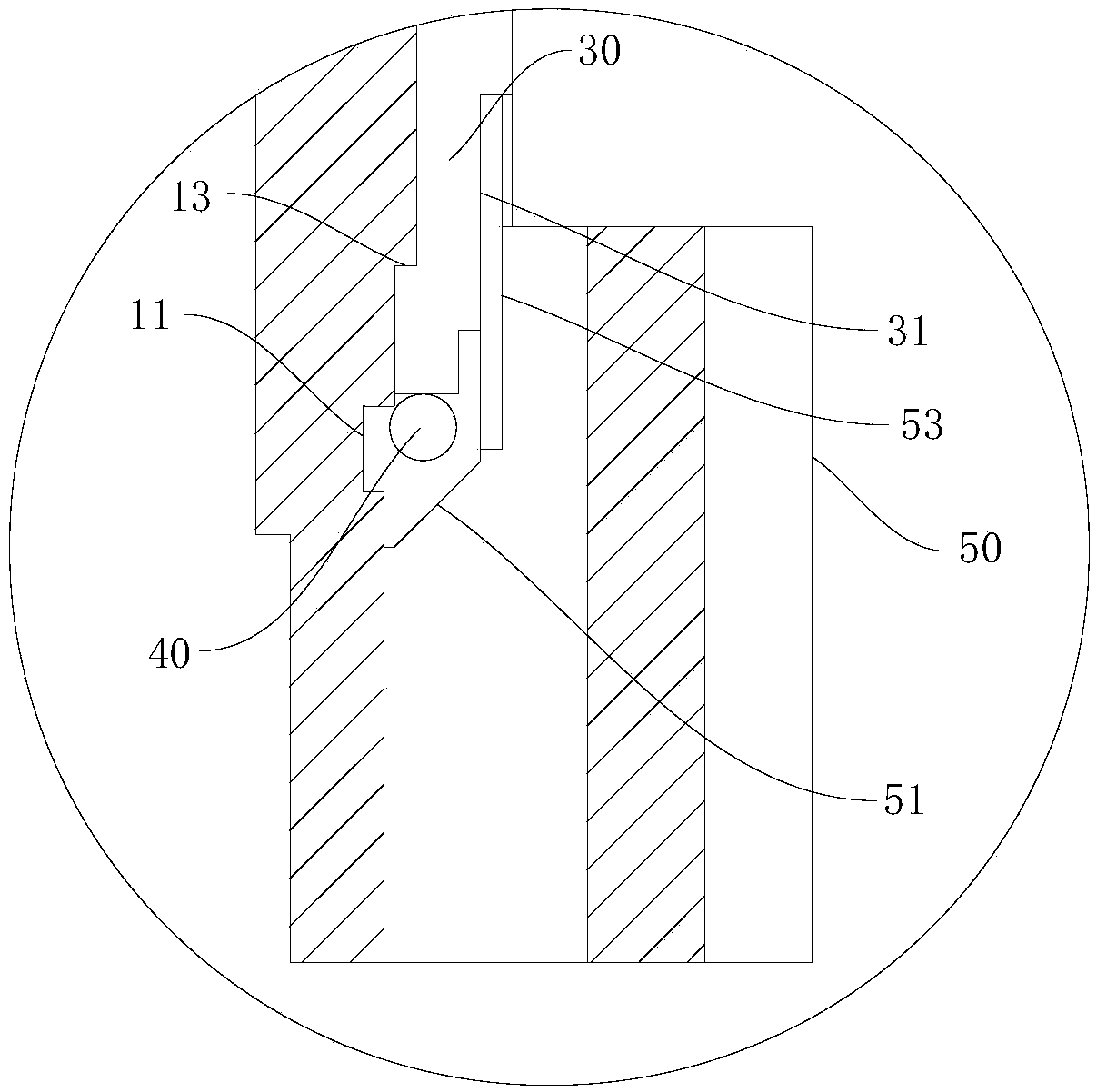

[0048] The fixed lamp body 10, the fixed lamp body 10 includes a first limiting portion 11 and a second limiting portion 13;

[0049] A connecting sleeve 30, the connecting sleeve 30 is sheathed on the fixed lamp body 10 and can abut against the second limiting portion 13, the connecting sleeve 30 includes a first connecting portion 31;

[0050] The elastic ring 40 is used for cooperating with the first limiting part 11 to limit the position; and

[0051] The built-in lamp cap 50, the built-in lamp cap 50 includes a pushing part 51 and a second connecting part 53 for matching with the first connecting part 31;

[0052] The connecting sleeve 30 can be detachably connected with the built-in lamp holder 50;

[0053] The general structure of the built-in downlight includes a first state and a second state. In the first state, the first connecting part ...

Embodiment 2

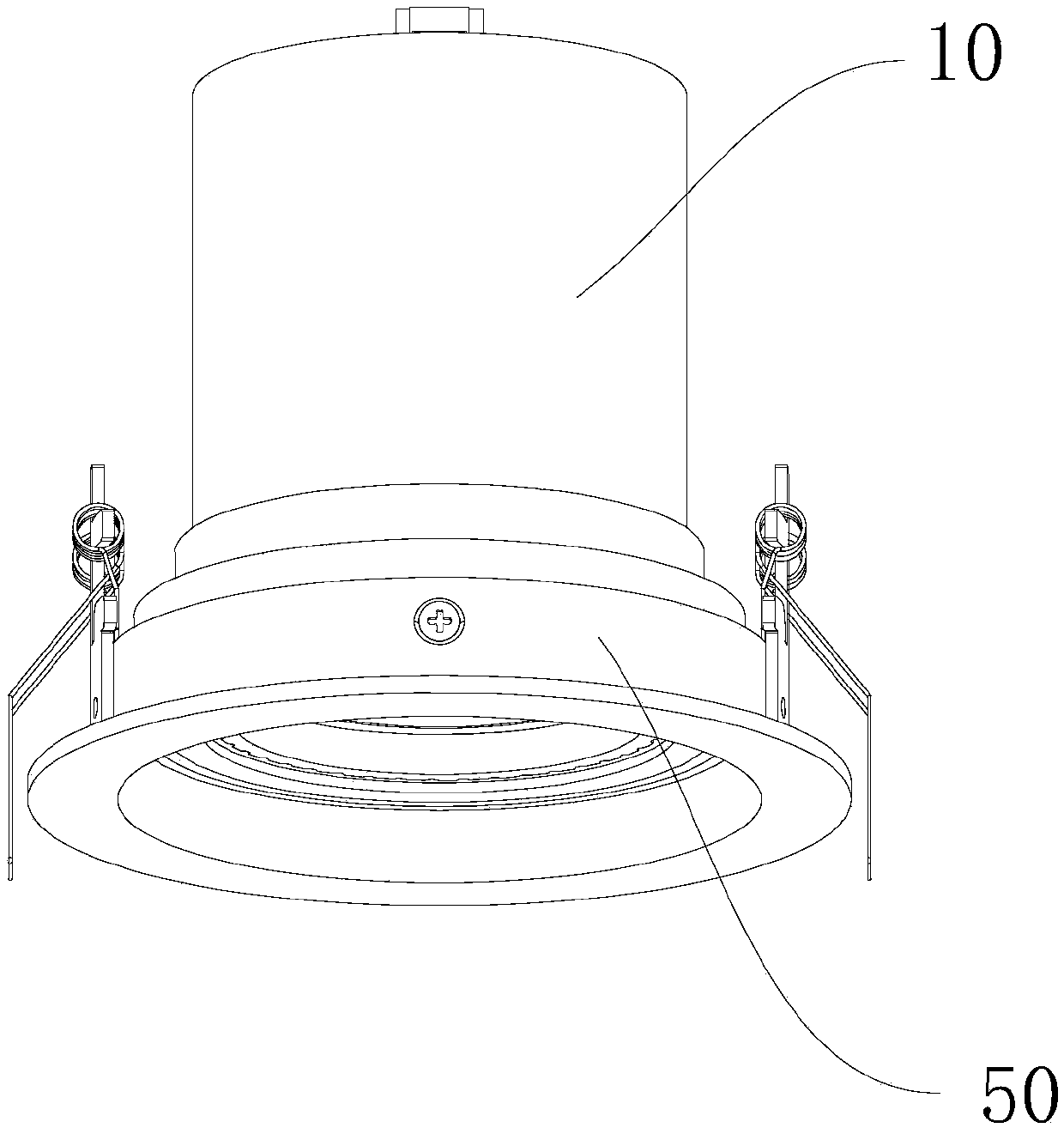

[0069] Please refer to Figure 5 with Image 6 , this embodiment provides a built-in combination lamp 200, including the general structure of the built-in downlight in Embodiment 1;

[0070] The connecting sleeve 30 is sleeved on the fixed lamp body 10 , the first connecting portion 31 is connected to the second connecting portion 53 , and the elastic ring 40 is inserted into the first limiting portion 11 .

[0071] Further, the built-in combination lamp 200 also includes a power connection part 201, the fixed lamp body 10 includes a plug connector 15, one end of the power connection part 201 is connected to the plug connector 15, and the other end is used to connect to a power source.

[0072] Further, the built-in lamp cap 50 has various sizes, and the hydrophobic second connecting portion 53 of the built-in lamp cap 50 of various sizes is the same, and any kind of built-in lamp cap 50 can be connected with the connecting sleeve 30 .

[0073] Further, the connecting sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com