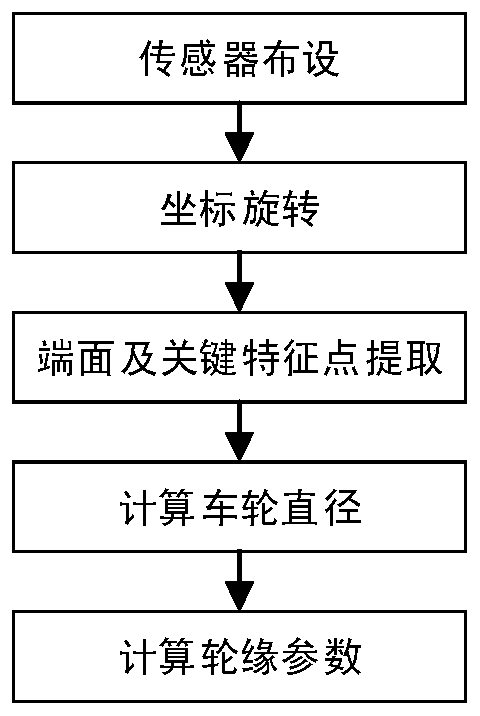

A non-contact urban rail vehicle wheel set size online detection method

An urban rail vehicle, non-contact technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of high cost of rails, inability to be widely used in urban rail transit, etc., and achieve the effect of simple structure device and simple detection principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

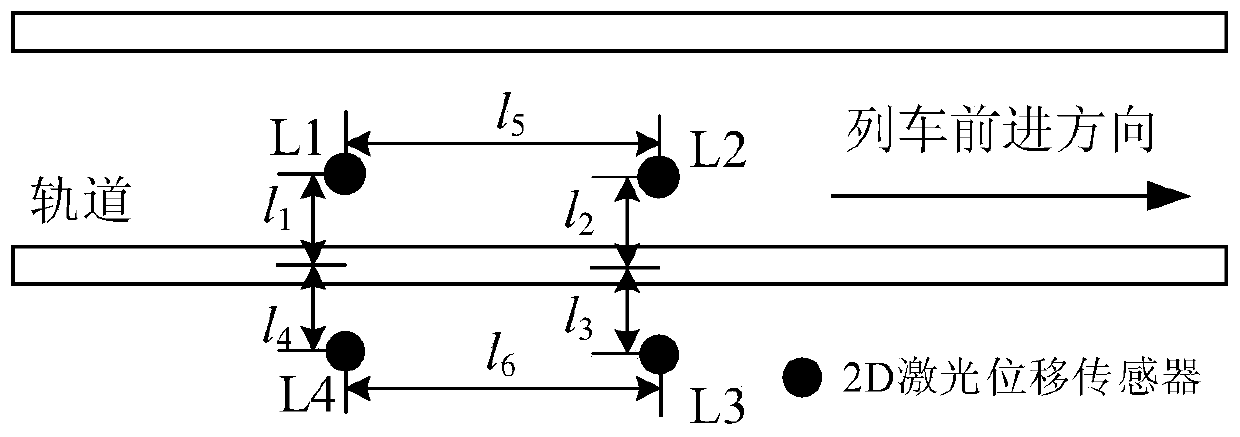

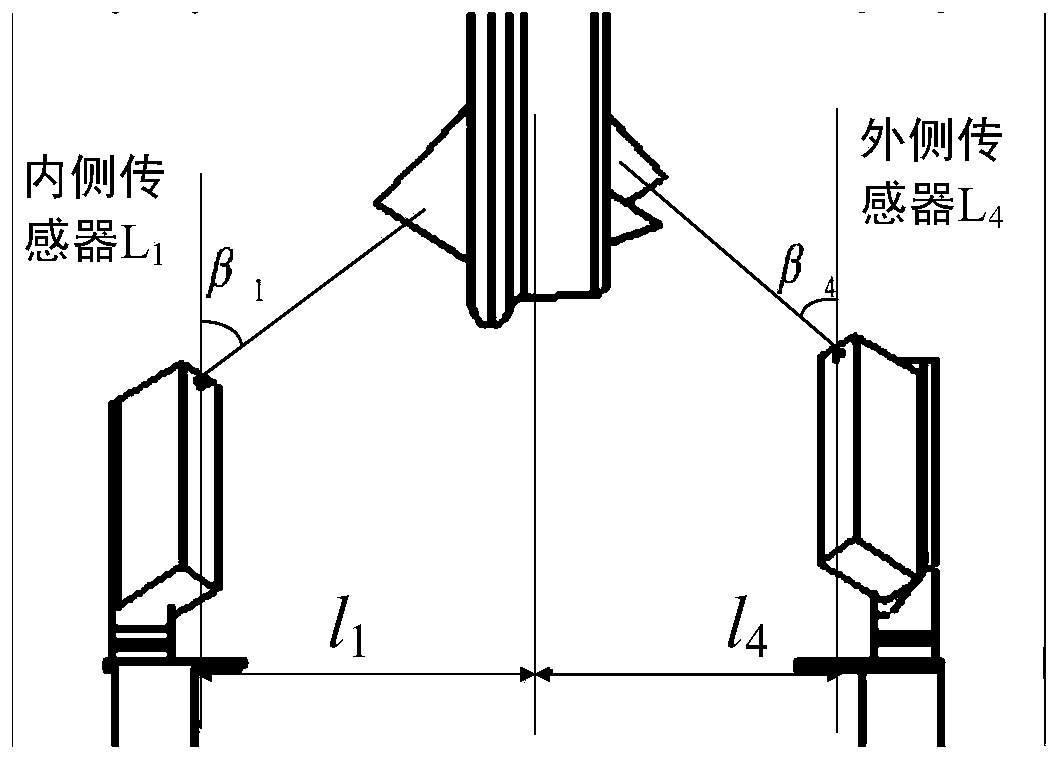

[0052] The first laser displacement sensor L1, the second laser displacement sensor L2, the third laser displacement sensor L3, and the fourth laser displacement sensor L4 are sequentially installed on the inner side of the track along the train advancing direction. The first laser displacement sensor L1 and the fourth laser displacement sensor L4 are arranged symmetrically about the track, and the second laser displacement sensor L2 and the third laser displacement sensor L3 are arranged symmetrically about the track. The vertical installation distance of the first laser displacement sensor L1, the second laser displacement sensor L2, the third laser displacement sensor L3, and the fourth laser displacement sensor L4 from the track is l 1 , l 2 , l 3 , l 4 Both are 350mm, the horizontal installation distance of the first laser displacement sensor L1 and the second laser displacement sensor L2 is l 5 The horizontal installation distance l from the third laser displacement s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com