Built-in type temperature and pressure compensation multidirectional gas roots flow meter

A waist wheel flowmeter, temperature and pressure compensation technology, applied in liquid/fluid solid measurement, volume measurement, measurement device and other directions, can solve the problems of high manufacturing cost, easy to be damaged by others, easy aging and damage of parts, etc. The effect of labor cost, convenient meter reading and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

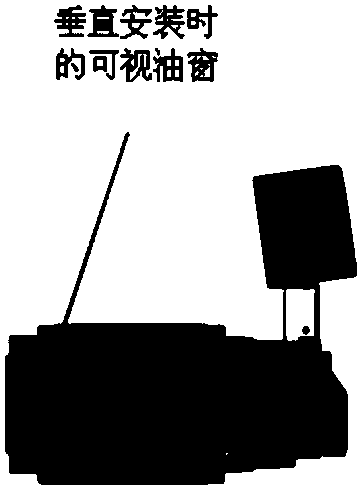

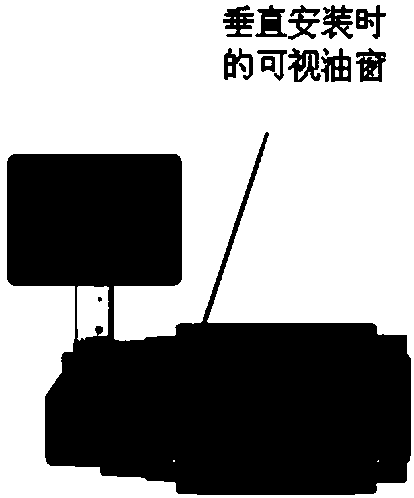

[0040] see Figure 1~Figure 7 as well as Figure 10~Figure 11, a built-in multi-directional gas waist wheel flowmeter with temperature and pressure compensation, including a housing 1, a rotating positioning plate 7, a counter and an integrator 26, two waist wheel rotors 4 are arranged in the housing 1, and the housing 1 The two ends are respectively connected with a front end cover 5 and a rear end cover 6. The front end cover 5 is provided with an intelligent sampling hole 14 and a counter samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com