Preparation method of metal complex lithium ion battery electrode material

A lithium-ion battery, metal complex technology, applied in battery electrodes, electrode manufacturing, electrolyte battery manufacturing and other directions, can solve the problems of low energy density, poor low temperature performance, etc., to achieve low requirements for synthesis equipment, low price, stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

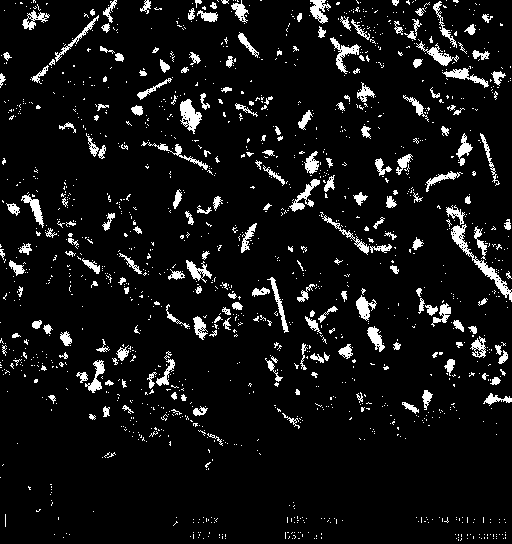

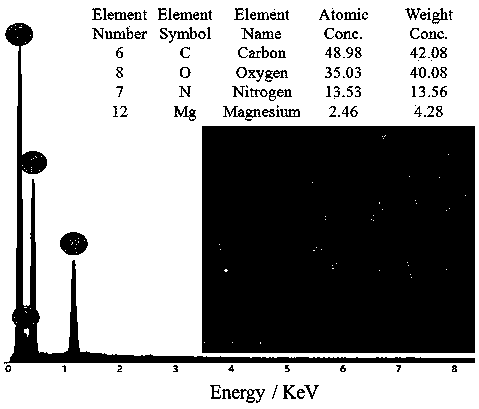

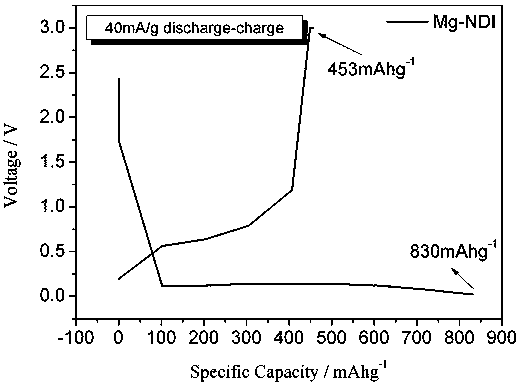

[0039] Example 1. Weigh 1.28 g (5 mmol) of magnesium nitrate hexahydrate and 1.48 g (2.5 mmol) of N,N-bis(5-isophthalic acid)-1,4,5,8-naphthalimide , Add 30ml DMF, then add 2ml of 3mol / L hydrochloric acid, and stir for 30min at room temperature. The stirred mixture was added to a 50ml Teflon autoclave, and the sealed reactor was placed in an oven at 95°C for two days, and then naturally cooled to room temperature to obtain yellow-brown block crystals. The synthesized complex was soaked in ethanol for 24 hours, filtered, and vacuum dried at 80°C for 12 hours to remove the solvent molecules in the pores of the complex to obtain the activated complex Mg-NDI. The dried Mg-NDI was ground through a 300 mesh sieve. According to the metal complex Mg-NDI, polyvinylidene fluoride (PVDF), conductive carbon black Super-P according to the mass ratio of 60:10:30 to prepare a mixture, add the solvent N-methylpyrrolidone (NMP), and stir for 2h to prepare Viscous slurry electrode material. T...

Embodiment 2

[0041] Example 2: 5, 6, 7, 8, weigh 1.28 g (5 mmol) of magnesium nitrate hexahydrate and 1.48 g (2.5 mmol) of N,N-bis(5-isophthalic acid)-1,4, 5,8-Naphthalimide, add 30ml DMF, then add 6mol / L hydrochloric acid 2ml, and stir for 60min at room temperature. The stirred mixture was added to a 50ml Teflon autoclave, and the sealed reactor was placed in an oven at 95°C for two days, and then naturally cooled to room temperature to obtain yellow-brown block crystals. The synthesized complex was soaked in ethanol for 24 hours, filtered, and vacuum dried at 80°C for 12 hours to remove the solvent molecules in the pores of the complex to obtain the activated complex Mg-NDI2. The dried Mg-NDI2 was ground through a 300 mesh sieve. According to the metal complex Mg-NDI, polyvinylidene fluoride (PVDF), conductive carbon black Super-P according to the mass ratio of 50:10:40 to prepare a mixture, add the solvent N-methylpyrrolidone (NMP), and stir for 2h to prepare Electrode material viscous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com