Squirrel-cage type energy-saving motor

A squirrel-cage and squirrel-cage technology, applied in the field of squirrel-cage energy-saving motors, can solve the problem of high energy consumption, achieve good electrical conductivity, high density, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

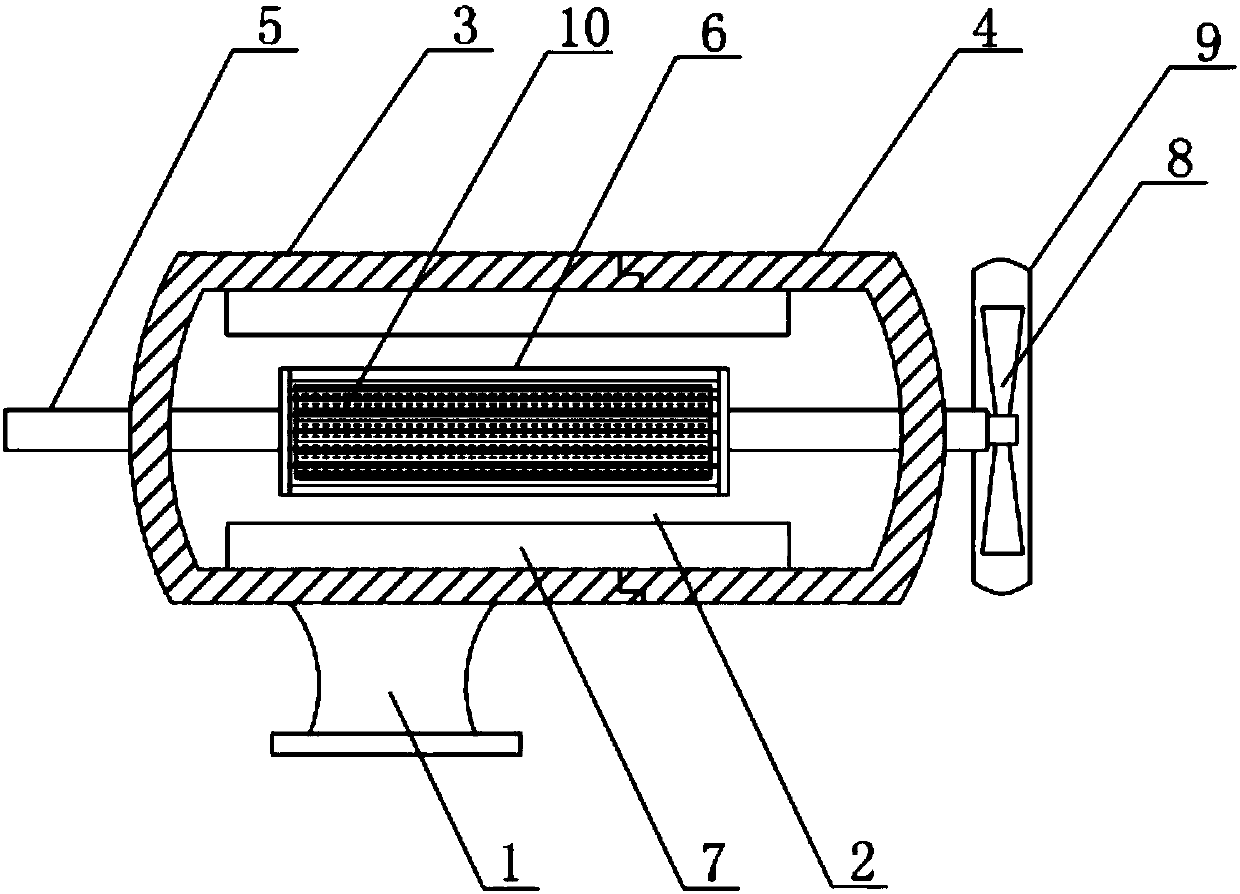

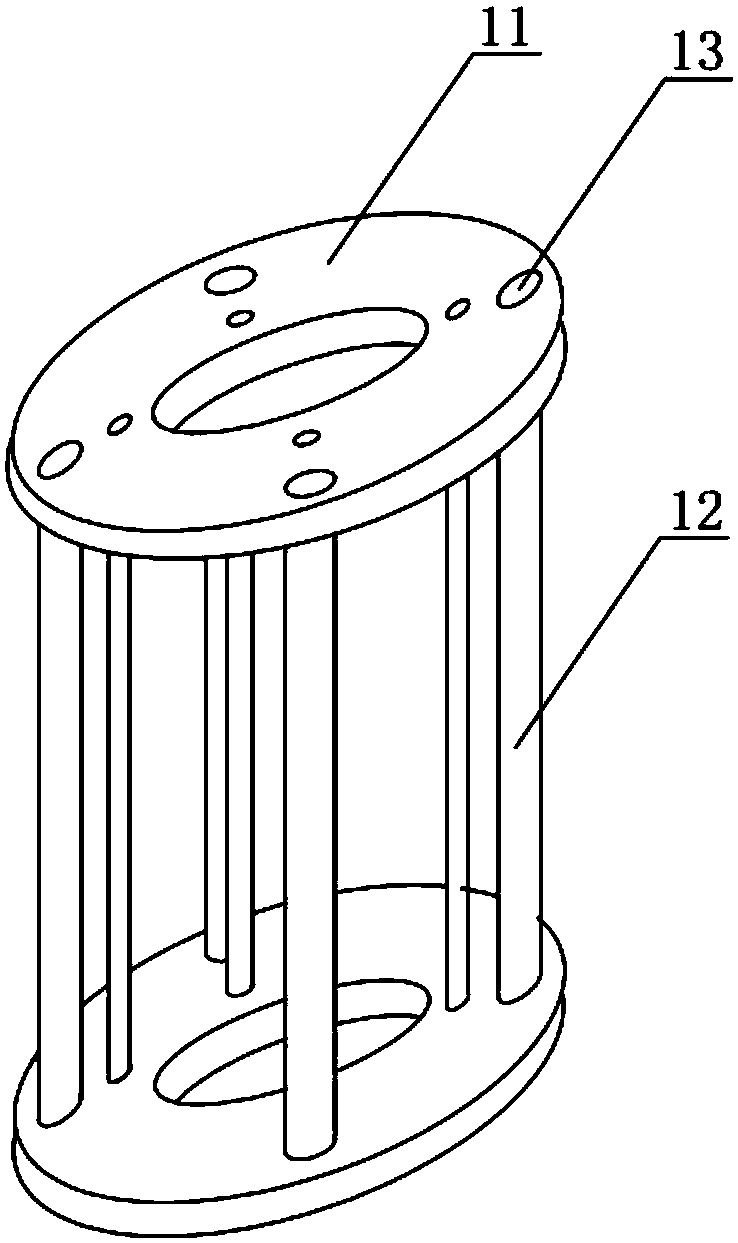

[0017] Such as Figure 1-2 As shown, a squirrel-cage energy-saving motor of the present invention includes a machine base 1, a body 2, a front end cover 3, a rear end cover 4, a rotating shaft 5, a squirrel-cage rotor 6 installed on the rotating shaft 5, a stator and a winding 7, An axial flow fan 8 is installed on the shaft outside the rear end cover 4, and an oval windshield 9 is arranged on the outside of the axial flow fan 8. The squirrel-cage rotor 6 is composed of a plurality of cold-rolled silicon steel sheets A rotor core 10 and a squirrel cage formed by lamination, the squirrel cage is a double-layer squirrel cage structure, consisting of two aluminum alloy end rings 11 and a number of copper guide bars 12, the outer edges of the aluminum alloy end rings 11 are arranged Two circles of circular through holes 13 are provided, and the diameters of the two circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com