Boiler, marine steam turbine propulsion system with the boiler, ship with the propulsion system, and boiler control method

A steam turbine and steam technology, applied in boilers, marine steam turbine propulsion systems with the boilers, ships with the propulsion systems, and boiler control fields, can solve control delays, main steam temperature, pressure instability, and long steam paths and other issues to achieve the effect of avoiding control delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

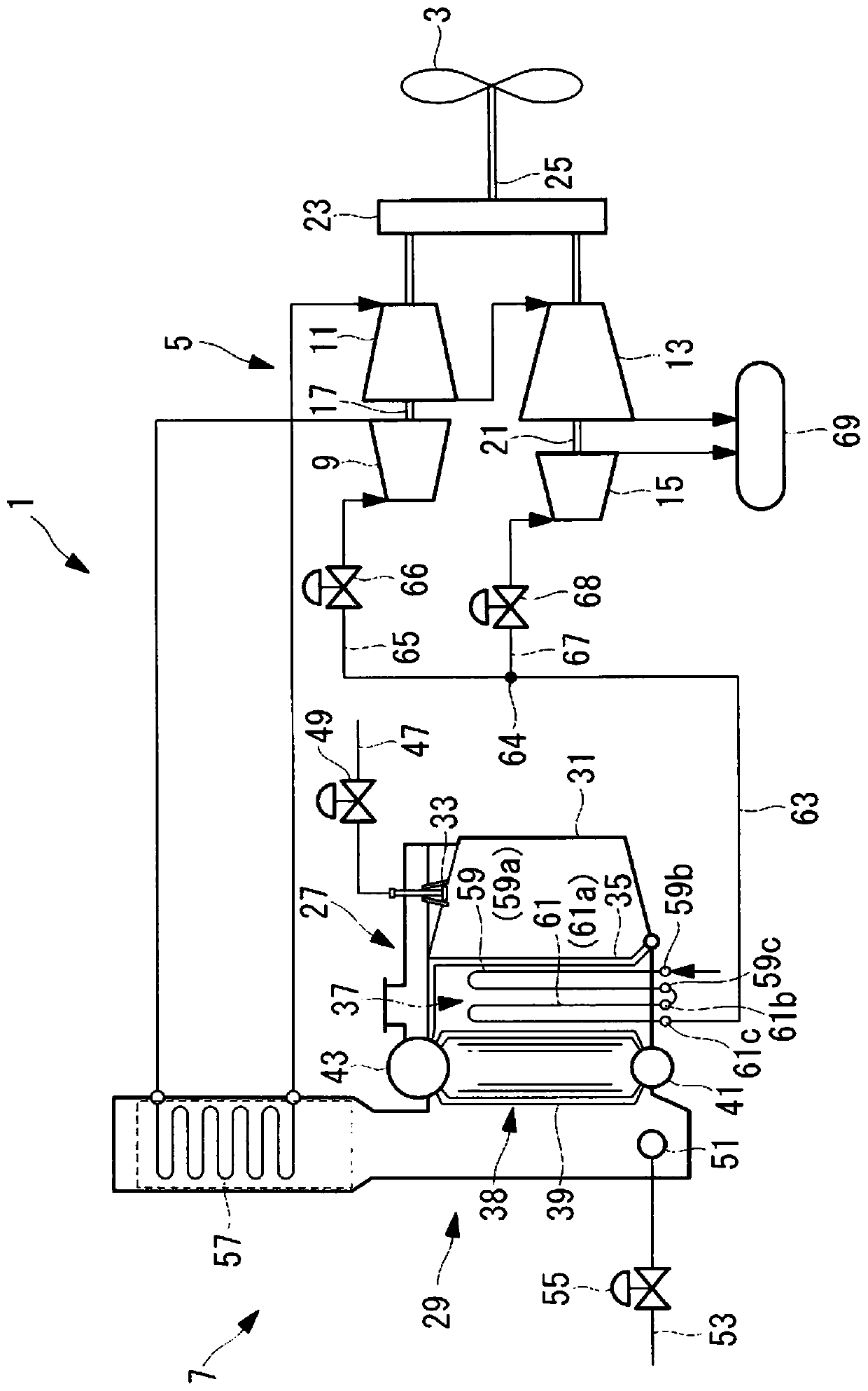

[0099] figure 1 The middle represents a marine steam turbine propulsion system 1 applied to a ship. The marine steam turbine propulsion system 1 has: a propulsion propeller (propeller) 3 that generates thrust in water; a steam turbine 5 that applies rotational force to the propeller 3 ; and a boiler 7 that supplies superheated steam as main steam to the steam turbine 5 .

[0100] The steam turbine 5 has a high-pressure turbine 9 , an intermediate-pressure turbine 11 , a low-pressure turbine 13 , and a backward turbine 15 . The high-pressure turbine 9 and the intermediate-pressure turbine 11 are connected via a common first rotating shaft 17 . The low-pressure turbine 13 and the reverse turbine 15 are connected via a common second rotating shaft 21 . The first rotating shaft 17 and the second rotating shaft 21 are arranged side by side, and their respective output end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com