Thermostat system with special inlet arrangement for commercial vehicles and its temperature sensing method

A technology for thermostats and commercial vehicles, which is applied in the direction of measuring devices, engine cooling, machines/engines, etc. It can solve problems such as the inability to sense the temperature of the coolant, so as to ensure the accuracy of temperature sensing, improve accuracy, and pertinence strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

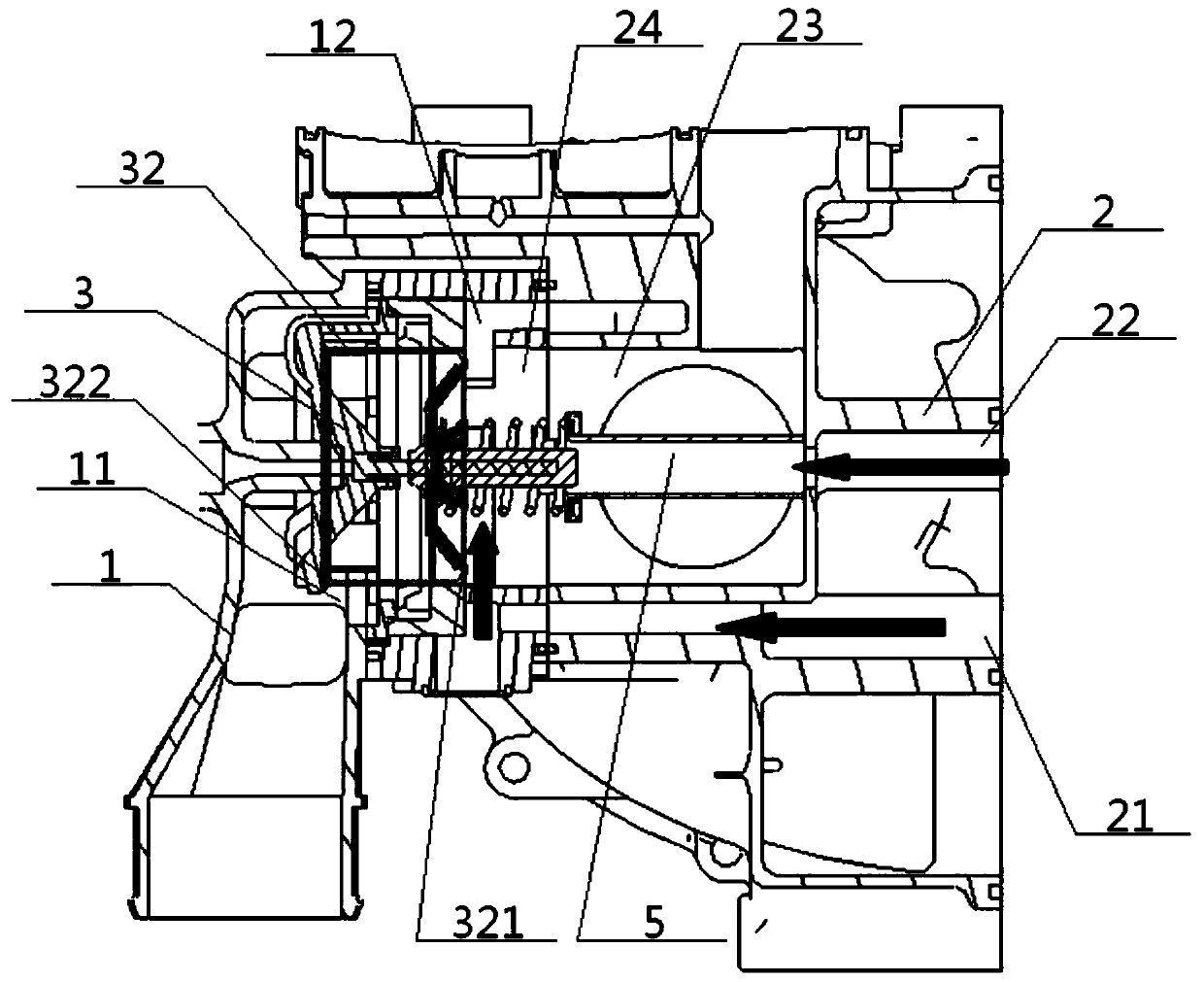

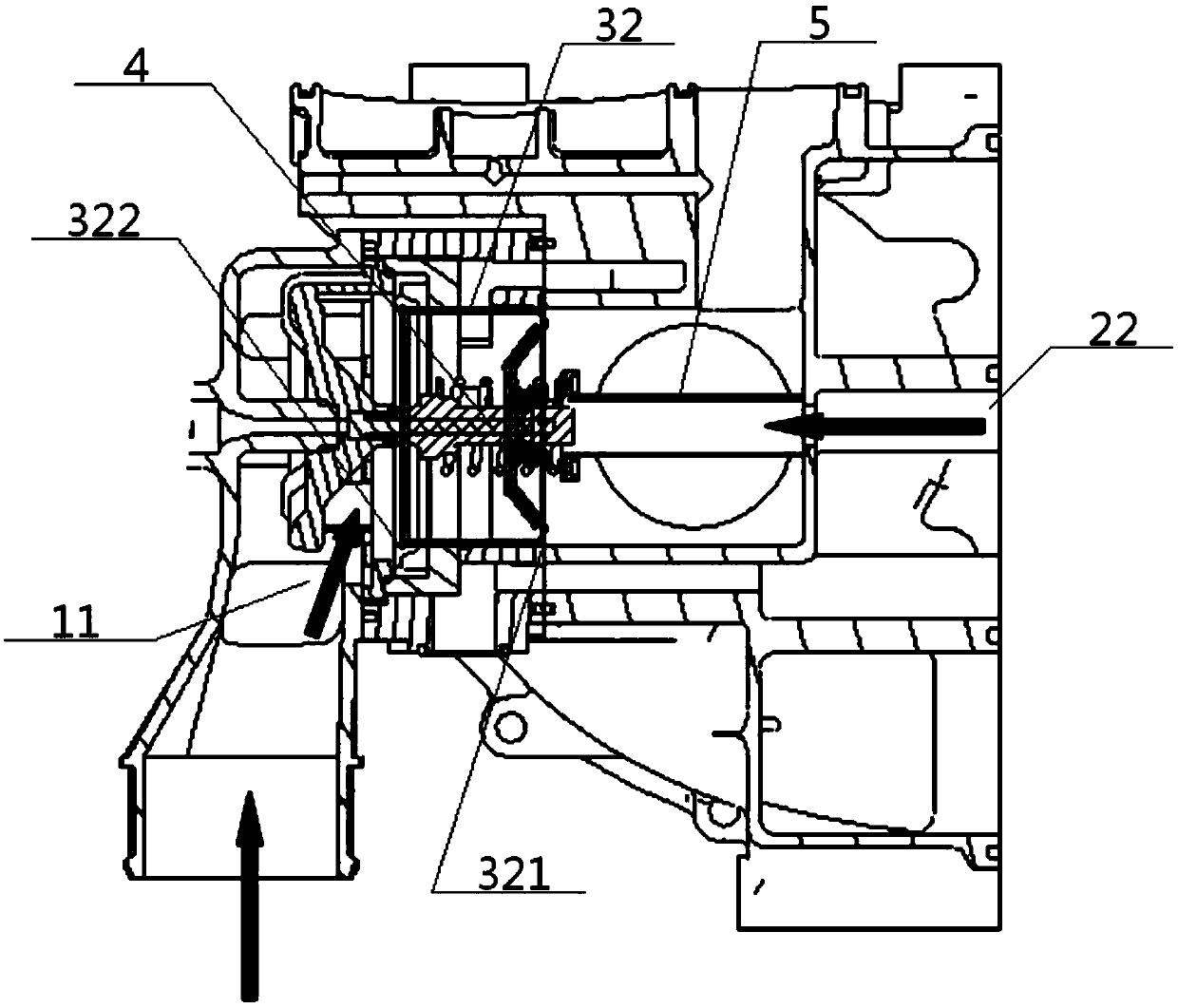

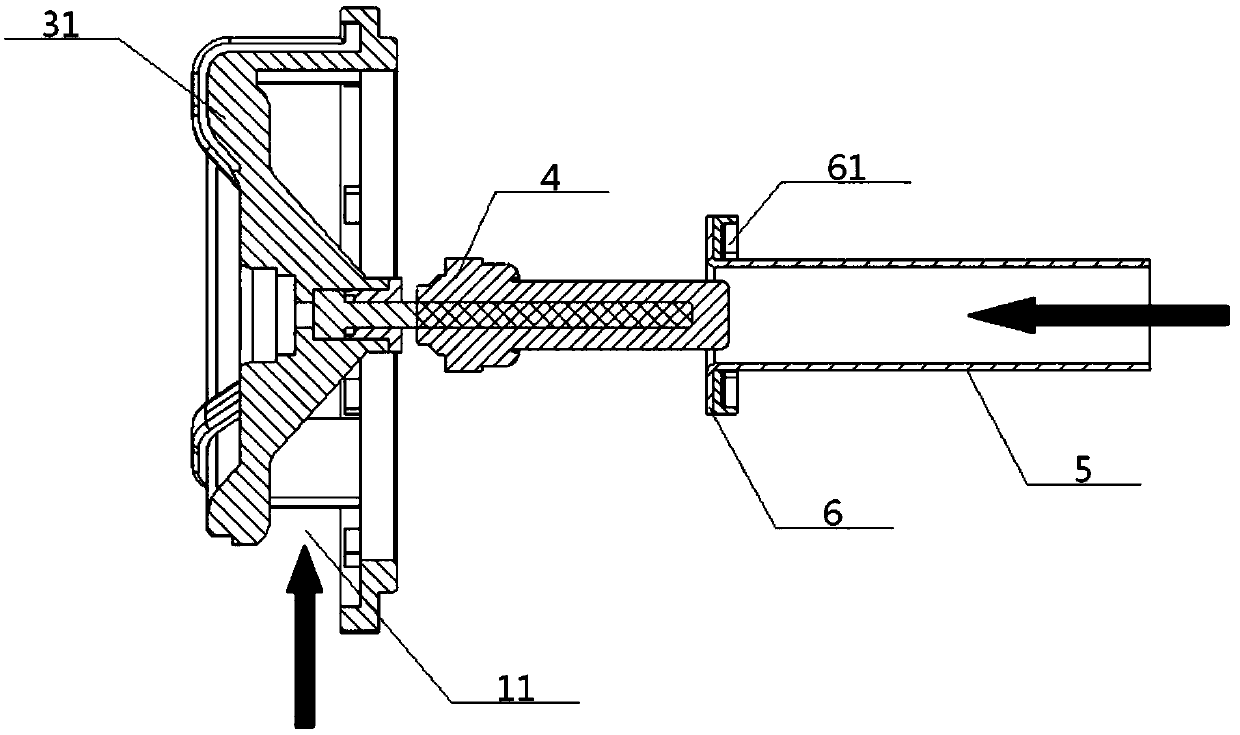

[0049] see Figure 1 to Figure 5 , a thermostat system with a special inlet arrangement for commercial vehicles, including a thermostat housing 1 connected to each other, an oil cooler module 2, a guide pipe 5, and a body coolant hole 22 opened in the oil cooler module 2 A thermostat 3 is provided near the oil cooler module 2 in the thermostat housing 1, and the paraffin temperature sensing part 4 in the thermostat 3 and the small circulation inlet 21 in the oil cooler module 2 or The large circulation inlet 11 in the thermostat housing 1 is connected; the thermostat 3 includes a back seat 31, a paraffin temperature sensing part 4 and a valve body 32, and the valve body 32 is arranged to slide back and forth along the paraffin temperature sensing part 4; The periphery of the back seat 31 is connected to the inner wall of the thermostat housing 1, the middle part of the back seat 31 is connected to one end of the paraffin temperature sensing part 4, and the other end of the par...

Embodiment 2

[0054] Basic content is the same as embodiment 1, the difference is:

[0055] Structurally: when the valve body 32 slides along the front of the paraffin temperature sensing part 4 to the end point, the bottom of the valve body 32 is in close cooperation with the small circulation inlet 21; when the valve body 32 slides to the end point along the paraffin temperature sensing part 4, The bottom of 32 is in close cooperation with large circulation inlet 11.

[0056] When in use: when the thermostat 3 is opened, it means that when the valve body 32 slides along the front of the paraffin temperature sensing part 4 to the end point, the bottom front end 321 of the valve body 32 closes the small circulation inlet 21, and at the same time, the bottom rear end 322 of the valve body 32 is released. The closure of the large circulation inlet 11; the closure of the thermostat 3 refers to: when the valve body 32 slides to the end point along the paraffin temperature sensing part 4, the fr...

Embodiment 3

[0058] Basic content is the same as embodiment 1, the difference is:

[0059] The guide tube 5 is set higher than the small circulation inlet 21, and the small circulation inlet 21 communicates with the paraffin temperature sensing part 4 after passing through the module inner cavity 23, the module outer cavity 24, and the housing cavity 12 in sequence. The large circulation inlet 11 communicates with the paraffin temperature sensing part 4 after passing through the shell cavity 12, the large circulation inlet 11 is set lower than the draft tube 5, and the horizontal distance between the large circulation inlet 11 and the cooling liquid hole 22 of the body is larger than the small one. The horizontal distance between the circulation inlet 21 and the coolant hole 22 of the machine body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com