Material gas concentration control system

A material gas and control system technology, applied in the direction of control/regulation system, ratio control, non-electric variable control, etc., can solve the problems of over-limit measurement concentration, longer control time, longer stabilization time, etc., and achieve good responsiveness , good responsiveness, small time delay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

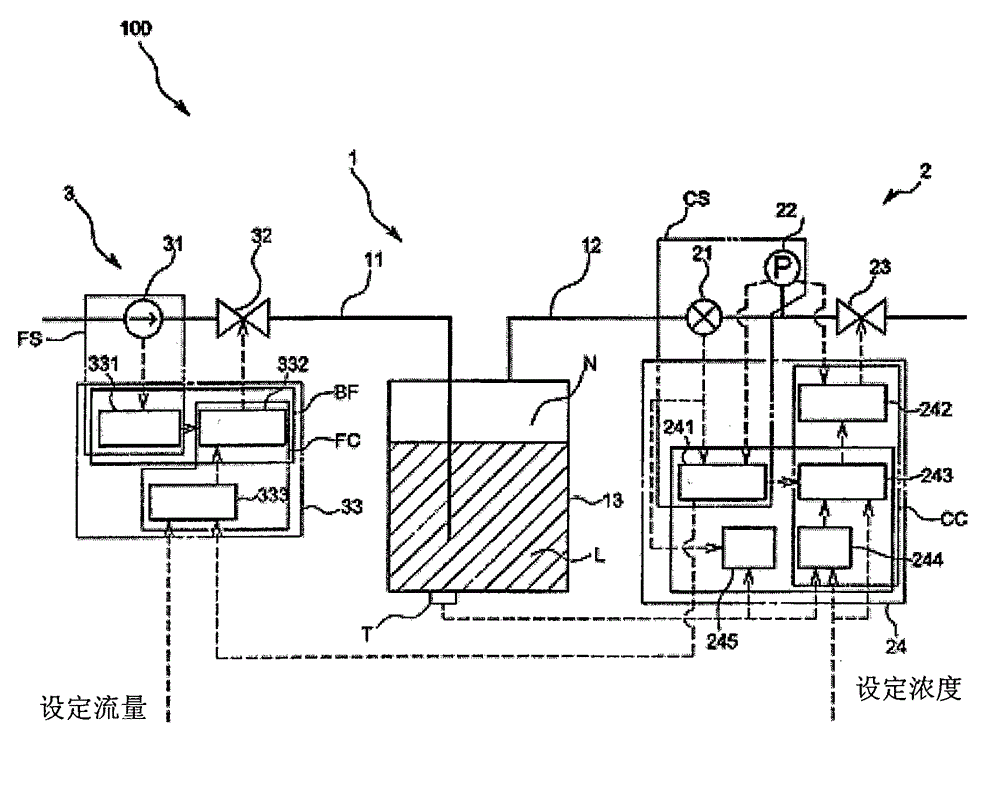

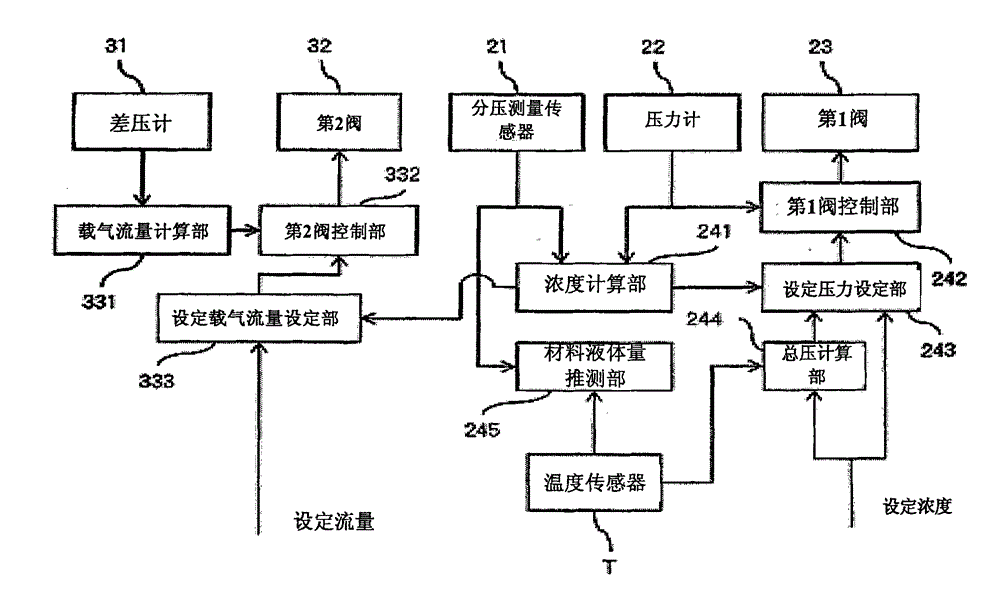

[0080] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

no. 1 approach 》

[0082] The material gas concentration control system 100 of the present invention is, for example, used to stably supply the IPA (Isopropyl Alcohol, isopropanol) concentration in the dry processing storage tank 13 of the wafer cleaning device used in the semiconductor manufacturing process. More specifically, the material gas concentration control system 100 of the present invention is for vaporizing the IPA material liquid L and supplying it to the bubbling system 1 in the drying process storage tank 13 . In addition, the IPA material liquid L corresponds to the material in the claims, and the bubbling system 1 corresponds to the gasification system in the claims. Here, even if the material is a solid material, the present invention can obtain the same effect. In addition, the present invention is not limited to the concentration control of the material gas obtained by vaporizing the IPA material liquid L. For example, it can also be used for concentration control in a CVD (...

no. 2 approach 》

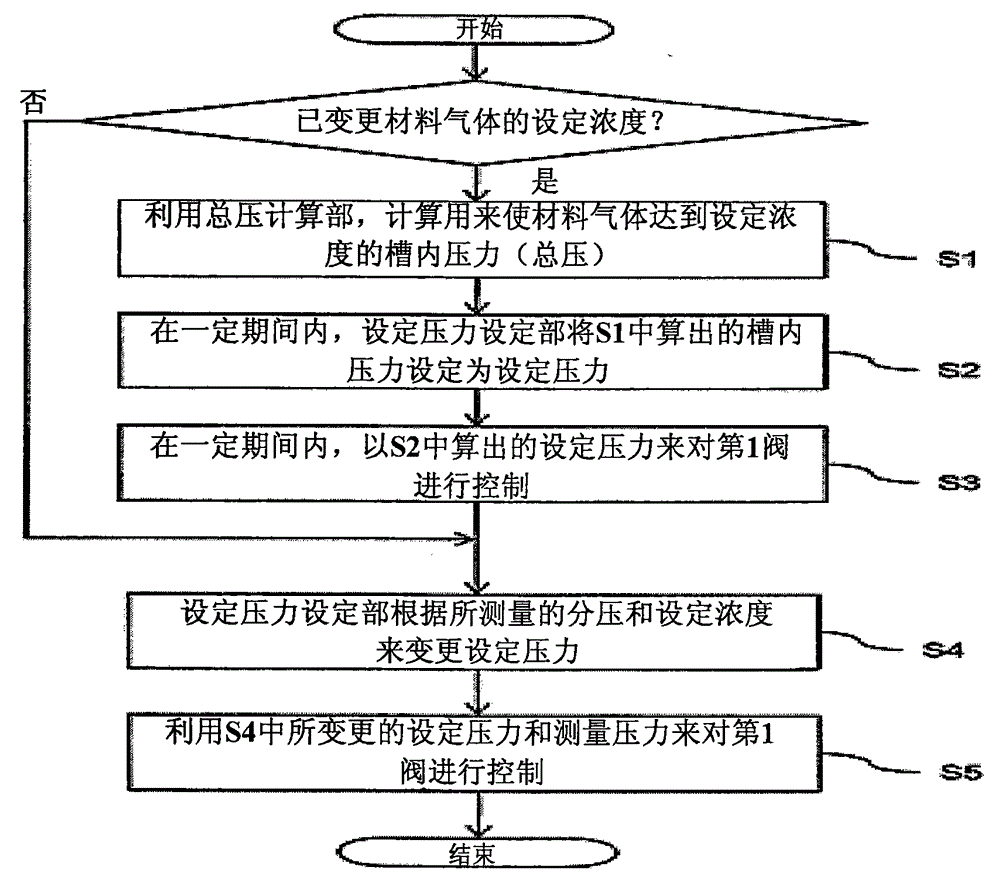

[0147] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. The composition of the second embodiment is the same as that of the first embodiment, such as figure 1 and figure 2 shown. Moreover, the actions related to concentration control are also the same as those in the first embodiment, such as image 3 and Figure 4 shown.

[0148] In the second embodiment, the operation and effect of the concentration control of the material gas in a state where the material liquid L is reduced will be described in detail. Figure 7 An example of the result when the concentration control of the material gas as described above is performed in a state where the material liquid L is reduced is shown. For a certain period of time after the set concentration is changed, the pressure in the storage tank at which the saturated vapor pressure of the material gas reaches the set concentration under the saturated vapor pressure of the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com