Correcting method for roundness of casting and correcting tool adopting same

A correction method and casting technology, applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to control all parts, poor roundness correction effect of circular cylinder orthopedic support device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

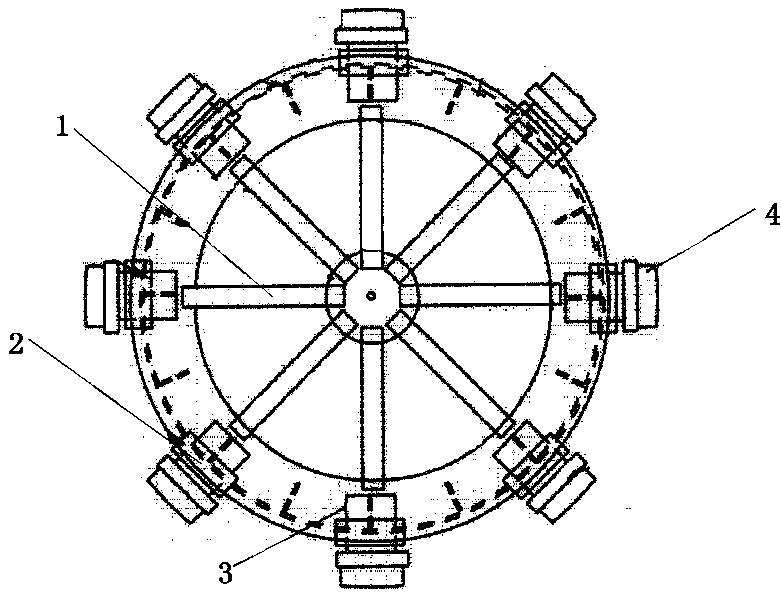

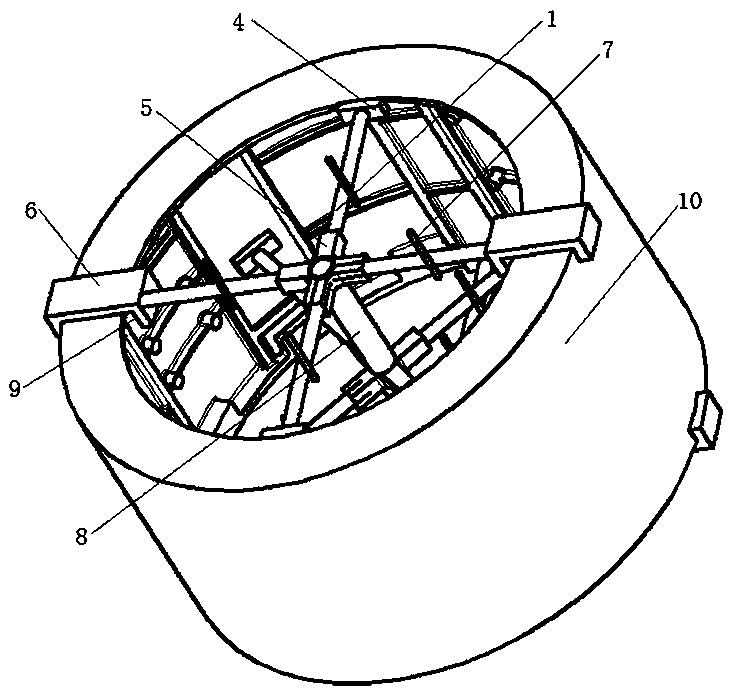

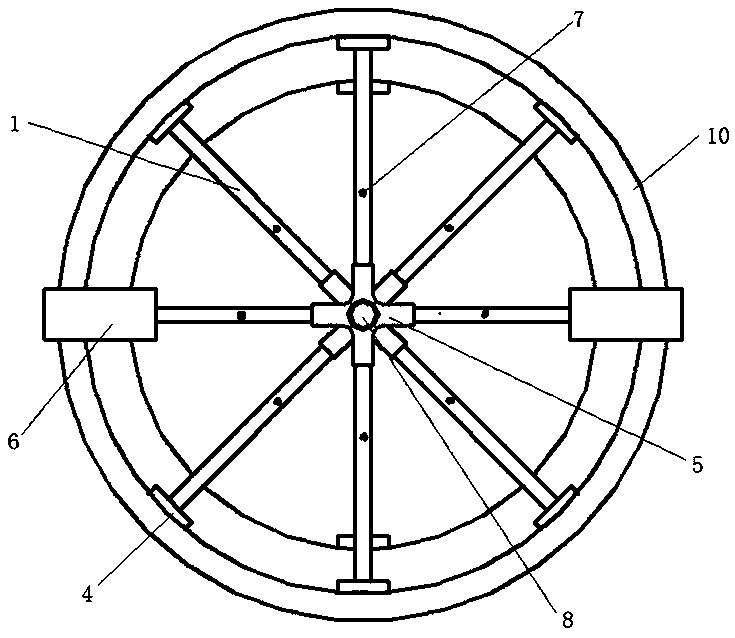

[0025] Embodiment 1 of the casting roundness correction tooling of the present invention, as Figure 2 to Figure 3 As shown, the roundness correction tooling includes a central steel pipe 8 with a diameter of 80cm, three cross positioning blocks 5 are arranged at intervals along the axial direction of the central steel pipe 8 on the central steel pipe 8, and the four directions of the cross positioning blocks 5 are A connection thread is provided, and the cross positioning block 5 is connected to the support pipe 1 through threads, and the cross positioning block 5 can rotate along the circumferential direction of the central rod. The support tube 1 located at both ends is provided with a pull block 6 for pulling inward the deformation part of the casting or a support block 4 for supporting the deformation part of the casting outward. The pull block 6 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com