Surface character printing device

A technology for printing and printing rods, which is applied in the field of high-firm surface printing devices, can solve the problems of inconvenient replacement of printing content, easy generation of volatile gas, air pollution, etc., so as to reduce labor fatigue, reduce sampling injury, work efficiency and improve The effect of improving the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

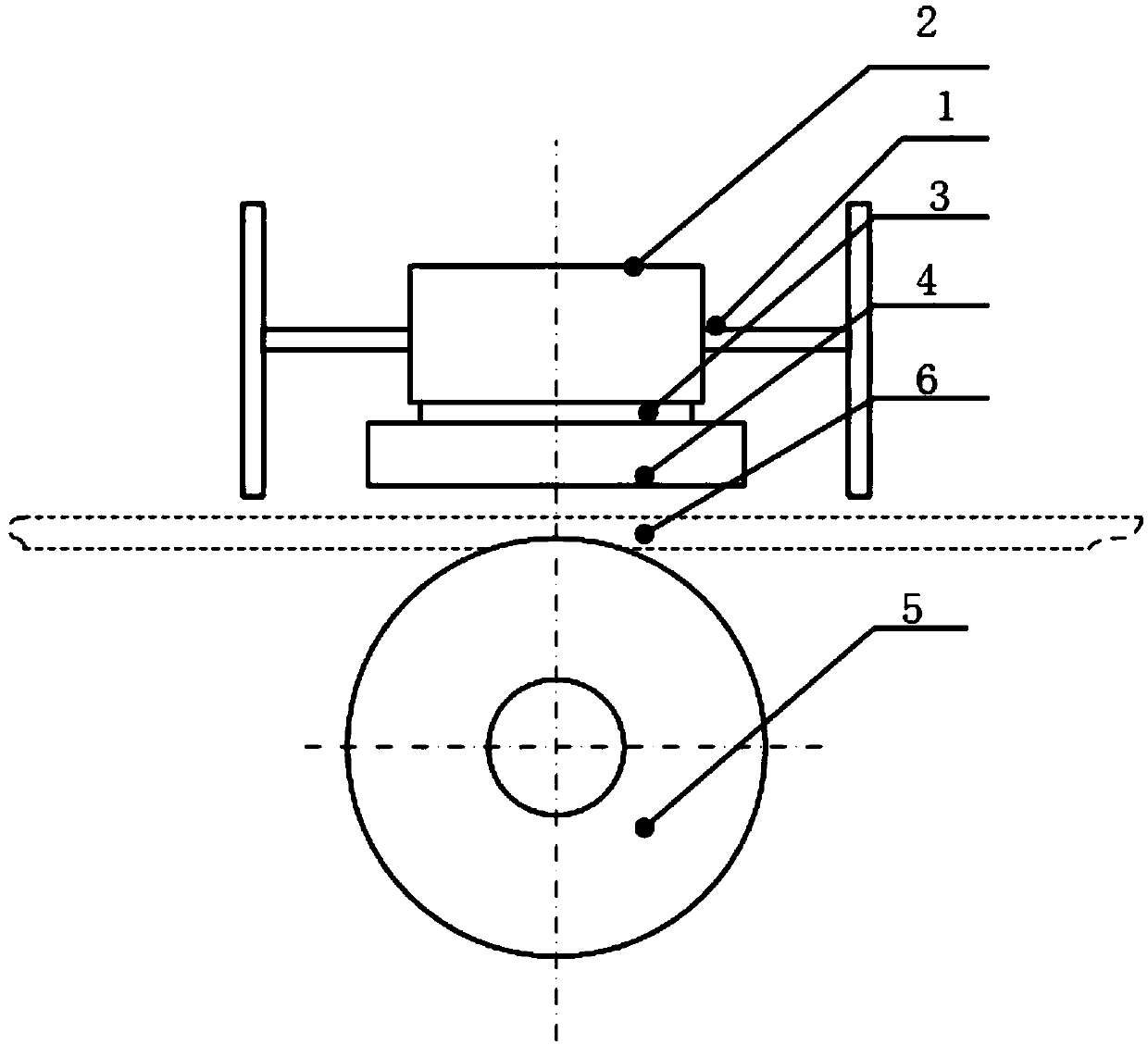

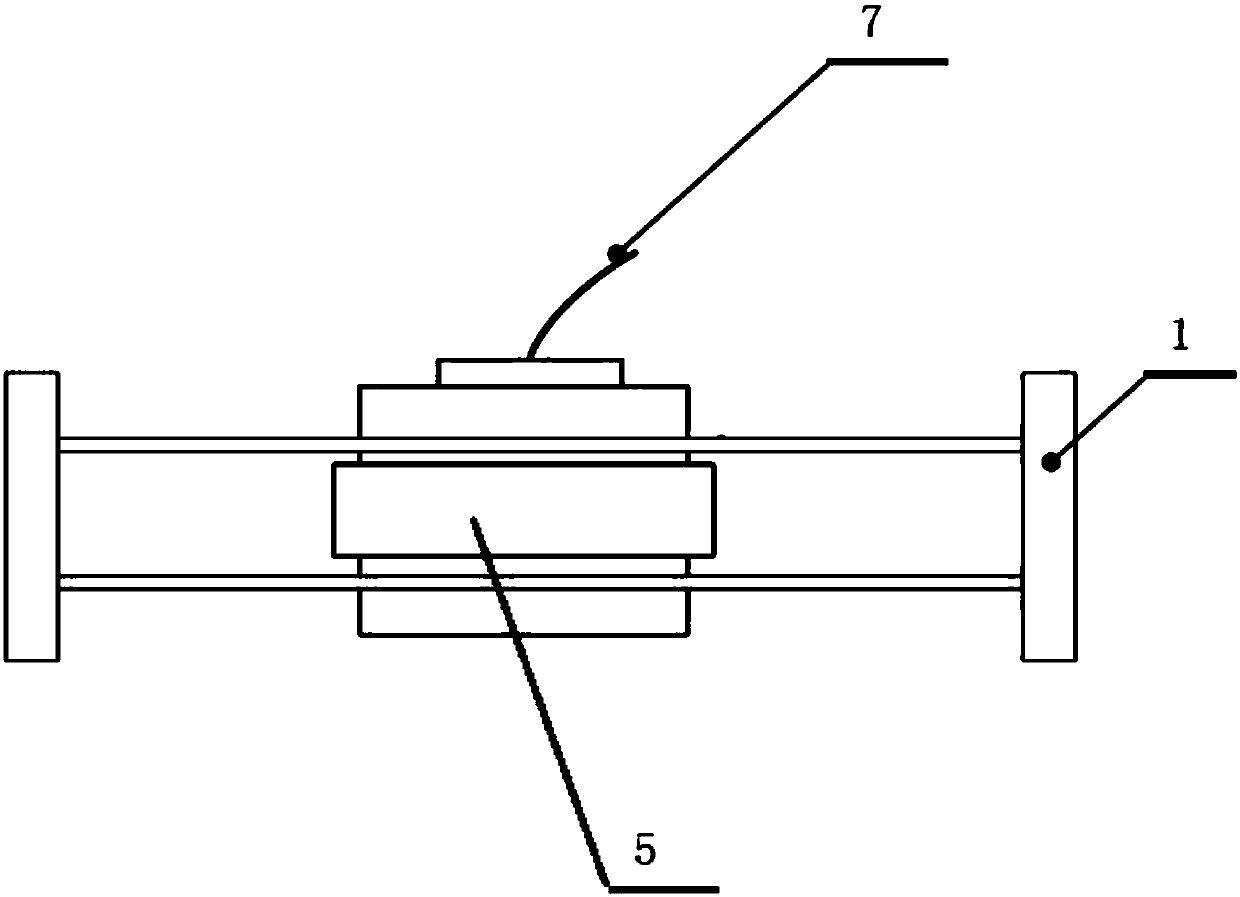

[0033] refer to Figure 1-2 As shown, a surface printing device is disclosed in this embodiment, which includes a frame 1, an ink tank 2 arranged on the frame 1, a driver 3, a printing assembly 4, and a wire passing wheel 5 cooperating with the printing device , the wire passing wheel 5 is arranged at the lower end of the printing assembly 4, and the above wire passing wheel 5 is used to transport the cable 6 to be printed.

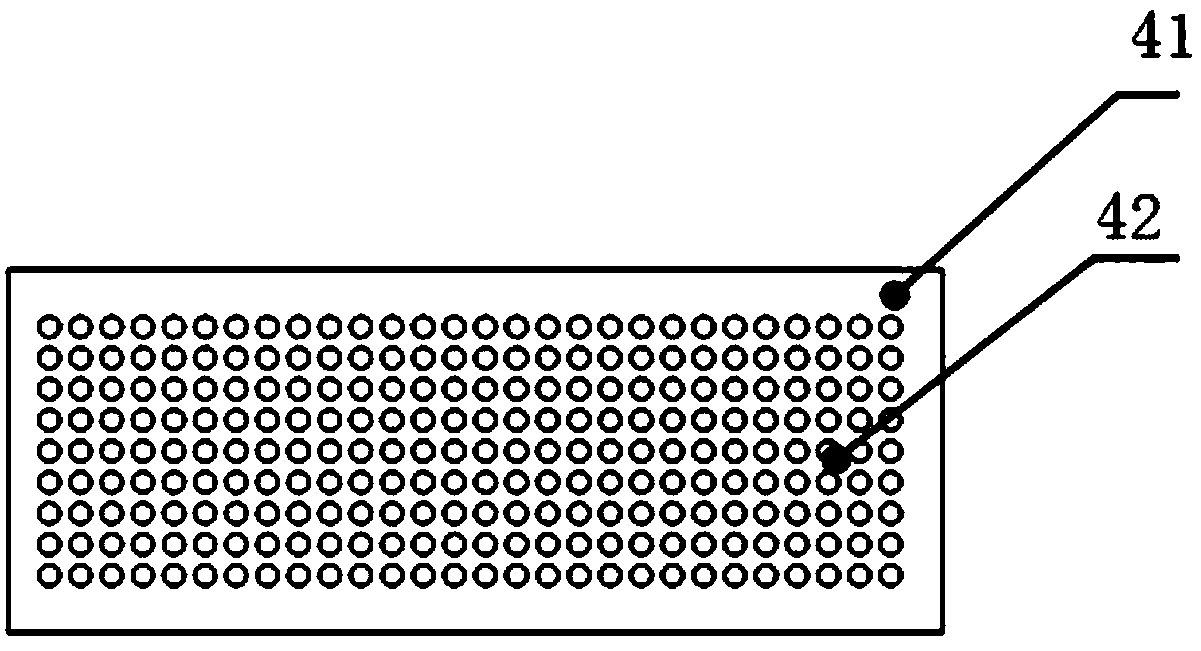

[0034] Such as Figure 3-4 As shown, the above-mentioned printing assembly 4 includes several printing units 40 and a printing plate 41 matched with the above-mentioned printing unit 40, the above-mentioned driver 3 is arranged between the above-mentioned ink tank 2 and the printing assembly 4, and the above-mentioned driver 3 drives the above-mentioned printing unit 40 to move up and down After printing is completed, the printing plate 41 is provided with a plurality of small holes 42 arranged in a matrix, and the arrangement of the plurality of printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com