Method for preventing artificial board from corner damaging during transporting

A technology of wood-based panels and corners, which is applied in the field of furniture, can solve the problems of damage to the corners of wood-based panels, collisions, etc., and achieve the effect of reducing maintenance costs and increasing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

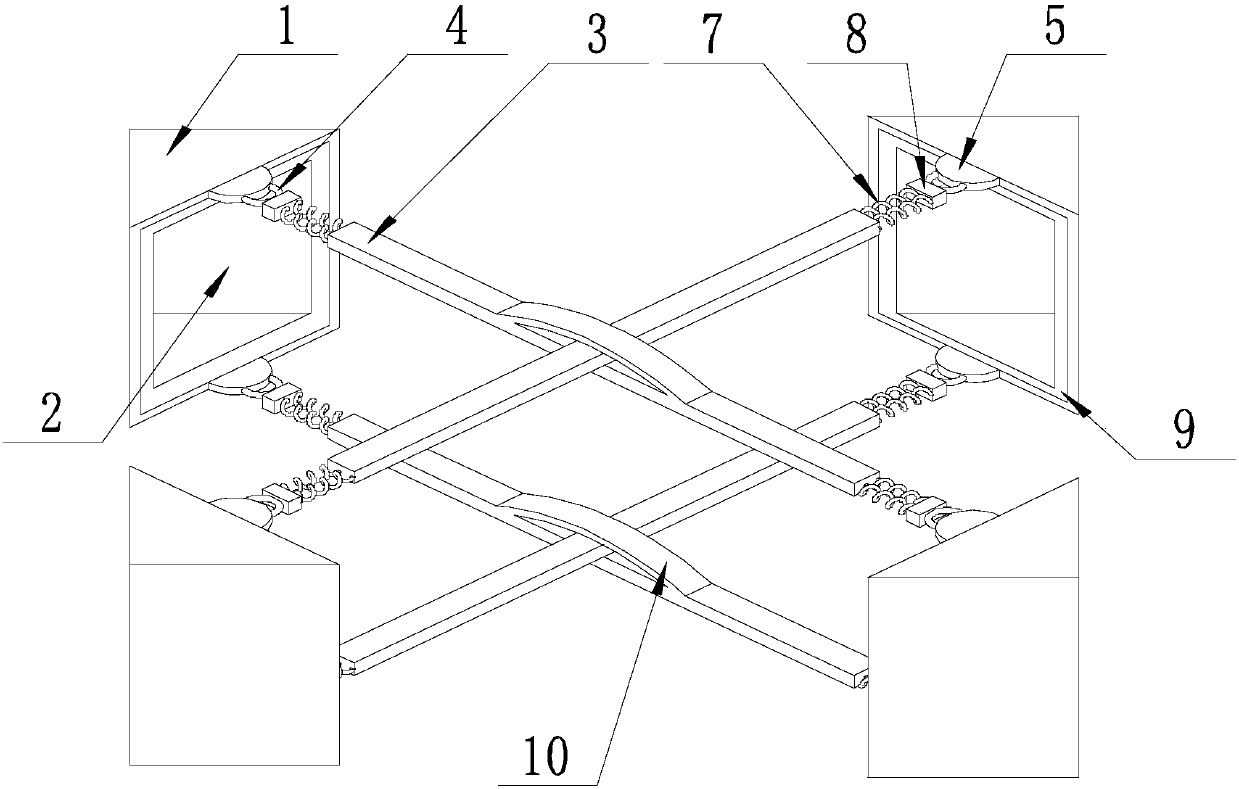

[0047]Such as Figure 1-Figure 6 As shown, the method for preventing damage to the corners of wood-based panels during transportation in the present invention, step A preparation: place the connection assembly on the wood-based panel, and make the two connection strips 3 in the connection assembly cross each other, and the connection strips The ends of 3 are respectively close to the right angle of a wood-based panel;

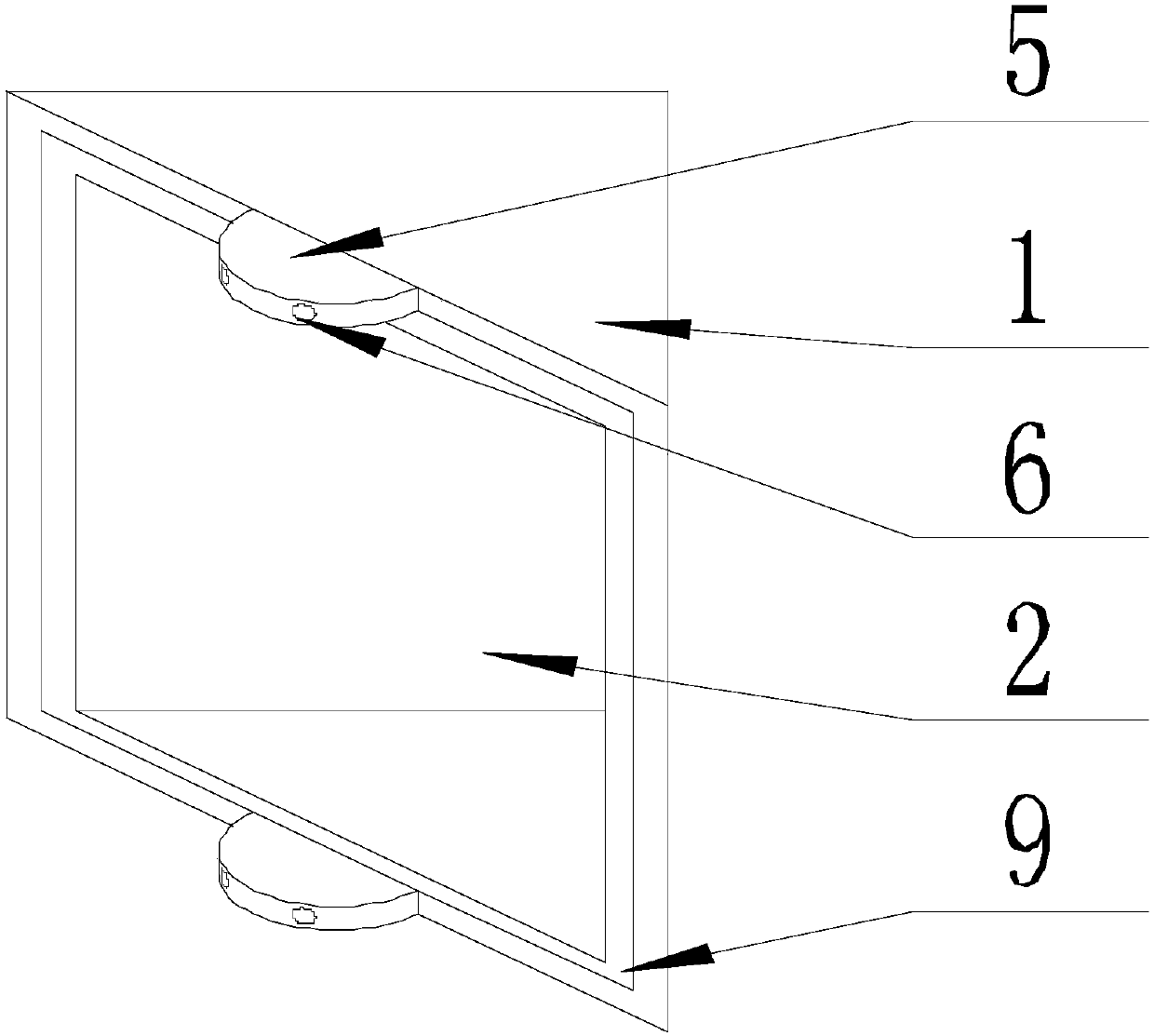

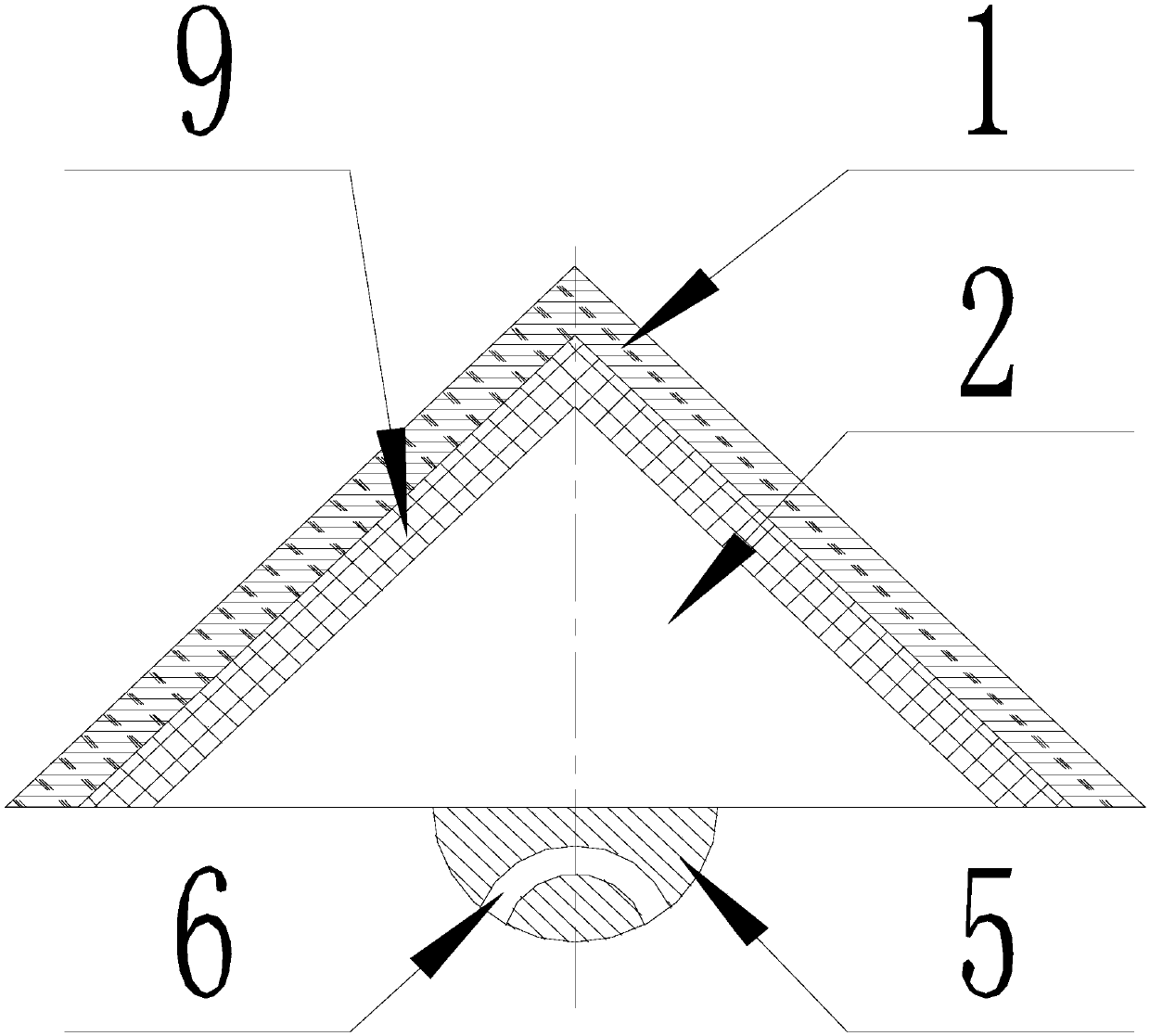

[0048] Step B wrapping: Place a corner block 1 at the end of the connecting strip 3, and the corner block 1 is sleeved on the corner of the wood-based panel through the strip groove 2 provided thereon, so that the wood-based panel The four corners are covered by corresponding strip grooves 2;

[0049] Step C: Fixing: hang the ends of the connecting strips 3 on the connecting holes 5 of the corresponding corner wrapping blocks 1 through a round hook 4 respectively.

[0050] The corner-wrapping block 1 is an isosceles right-angled triangular prism, the axis of ...

Embodiment 2

[0054] This embodiment is based on Embodiment 1 to further illustrate the present invention.

[0055] Such as Figure 1-Figure 6 As shown, in the method for preventing damage to the corners of wood-based panels in the present invention, a limiting plate 10 is arranged on one of the connecting strips 3, and the limiting plate 10 is an arc-shaped plate, and its inner concave surface faces the connecting strip Plate 3, the axis of which is perpendicular to the axis of connecting strip 3, and perpendicularly intersects with the vertical line of connecting strip 3, and the ends of limiting plate 10 are connected with connecting strip 3;

[0056] One end of another connecting strip 3 passes through the inner concave surface of the limiting plate 10, and the crossing angle between the connecting strips 3 is adjusted so that the connecting strip passing through the inner concave surface of the limiting plate 10 3 is parallel to the axis of the limiting plate 10.

[0057] The limitin...

Embodiment 3

[0065] This embodiment is based on Embodiment 1 to further illustrate the present invention.

[0066] Such as Figure 1-Figure 6 As shown, in the method for preventing damage to the corners of wood-based panels in the present invention, springs 7 and connecting plates 8 connected in sequence are arranged between the connecting strips 3 and the corresponding round hooks 4, and the expansion and contraction of the springs 7 The track is parallel to the axis of the corresponding connecting strip 3, one end thereof is connected with the connecting strip 8, the other end is connected with the connecting strip 3, and the end of the connecting strip 8 away from the spring 7 is connected with the round hook 4.

[0067] The springs 7 are all cylindrical helical tension springs, and there are two springs 7 between the connecting strip 3 and the corresponding round hook 4 .

[0068] The setting of the spring 7 can not only increase the telescopic length of the connecting strip 3, reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com