Electric double open inner swinging door

An in-swing door, electric technology, used in door/window accessories, power control mechanisms, buildings, etc., can solve the problems of unsightly appearance, low transmission efficiency, low reliability, etc., and achieve good triple sealing effect and reliable torque transmission. , the effect of good institutional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution will be described in detail below through a preferred embodiment and in conjunction with the accompanying drawings.

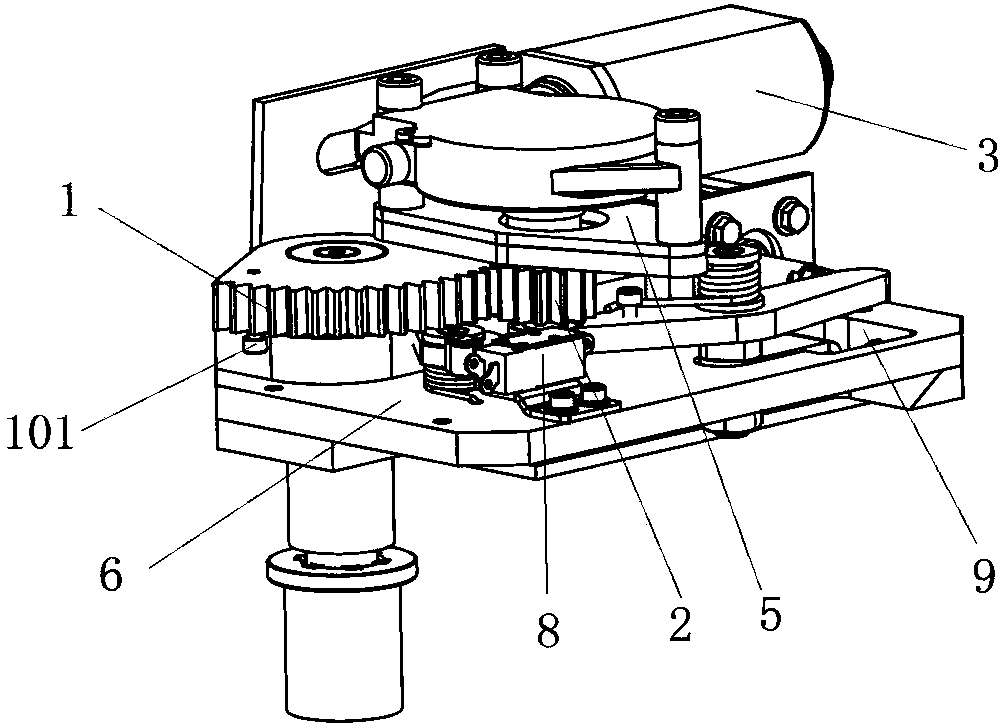

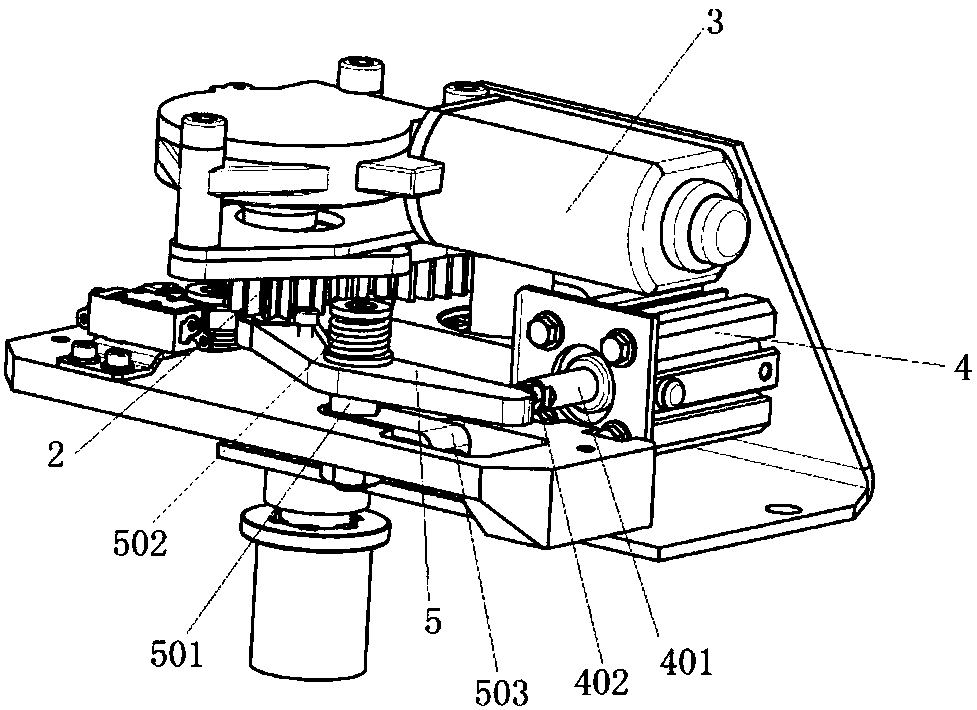

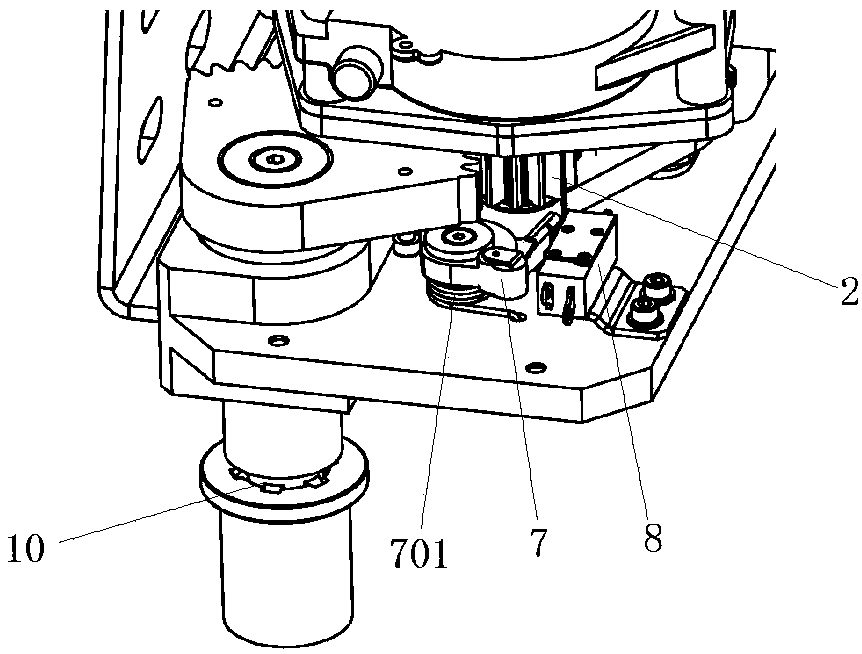

[0025] Such as Figure 1-3 As shown, an electric double-opening inner swing door includes a door shaft 11, a door leaf 12 rotating with the door shaft 11 and two driving devices for driving the door shaft 11 to rotate. The driving device is used to drive the inner swing door to open / close the door, including The door controller, the sector gear 1 coaxially driven with the door shaft 11 of the inner swing door, the driving mechanism for driving the sector gear 1 to rotate, and the unlocking mechanism for disengaging the drive mechanism from the sector gear 1, the sector gear 1 , the driving mechanism and the unlocking mechanism are all installed on the mounting plate 6, and the sector gear 1 is connected with the door shaft 11 of the inner swing door through the spline shaft 10.

[0026] The drive mechanism includes a motor gear 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com