Stereoscopic laser scratch film and preparation method and application thereof

A laser and three-dimensional technology, which is applied in the field of anti-counterfeiting, can solve the problems of anti-counterfeiting patterns without three-dimensional sense, no brightness, and health hazards to operators, etc., and achieve novel and diverse anti-counterfeiting methods, increase the difficulty of imitation, and have good three-dimensional fantasy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

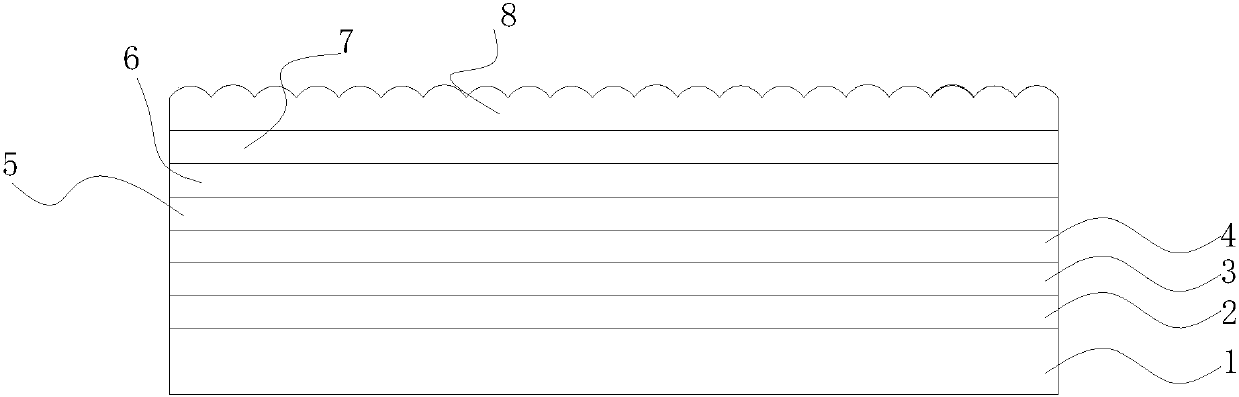

[0039] Such as figure 1 As shown, a three-dimensional laser scratch film includes a base layer 1, a separation layer 2 is superimposed on the base layer 1, a laser molded layer 3 is superimposed on the separation layer 2, and a printing layer is superimposed on the laser molded layer 3 4. An aluminum film layer 5 is superimposed on the printing layer 4, a waterproof and wear-resistant layer 6 is superimposed on the aluminum film layer 5, a brightening layer 7 is superimposed on the waterproof and wear-resistant layer 6, and the brightening layer A grating layer 8 is superimposed on the 7 . The base layer 1 is used as the carrier of the wear-resistant, waterproof, three-dimensional laser scratch film; the separation layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com