Powertrain lash management

A gap adjustment and gap area technology, applied in the direction of external condition input parameters, control devices, driver input parameters, etc., can solve driver discomfort and other problems, achieve the effect of improving driving performance, improving gap adjustment, and minimizing torque changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

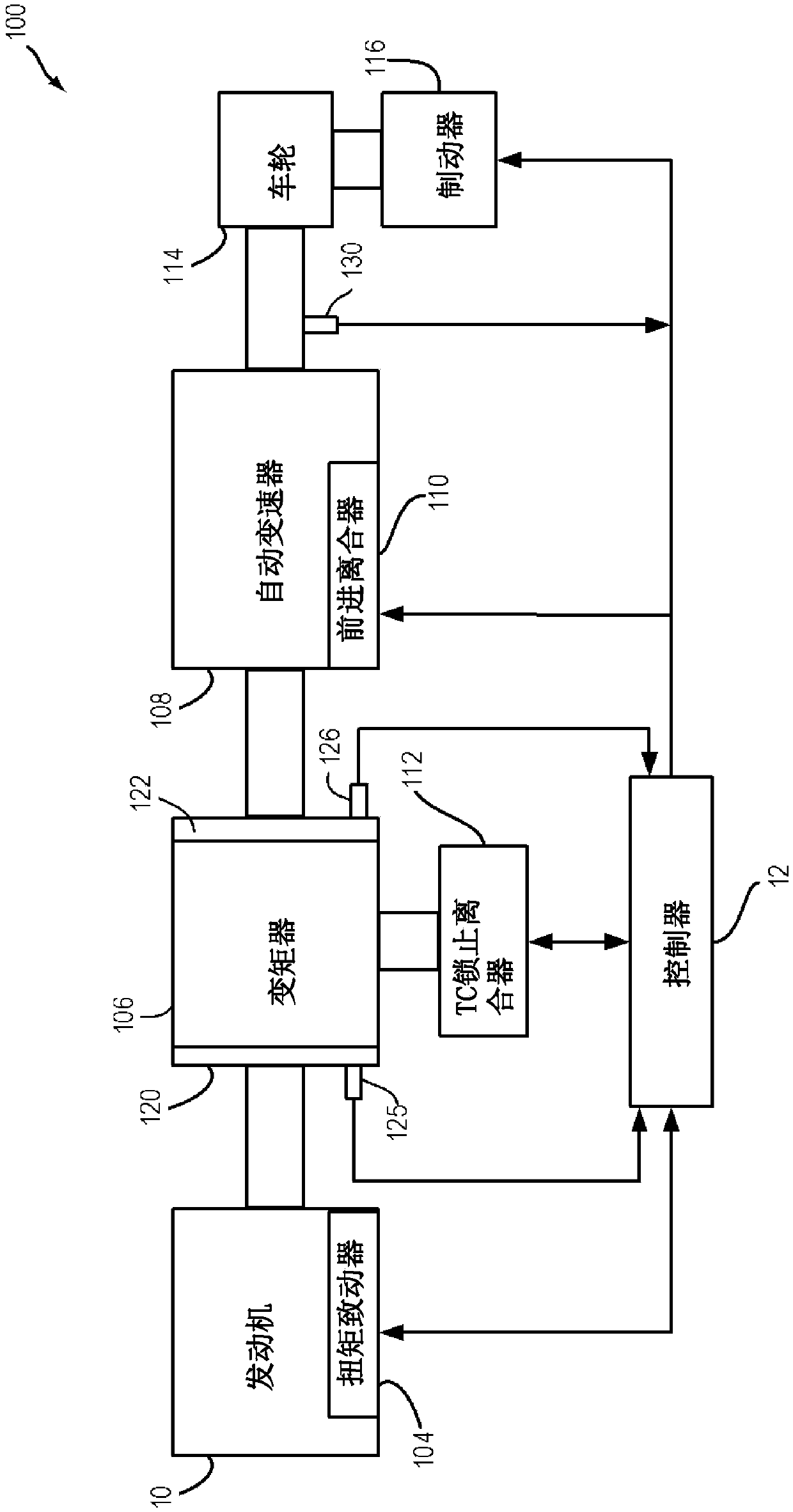

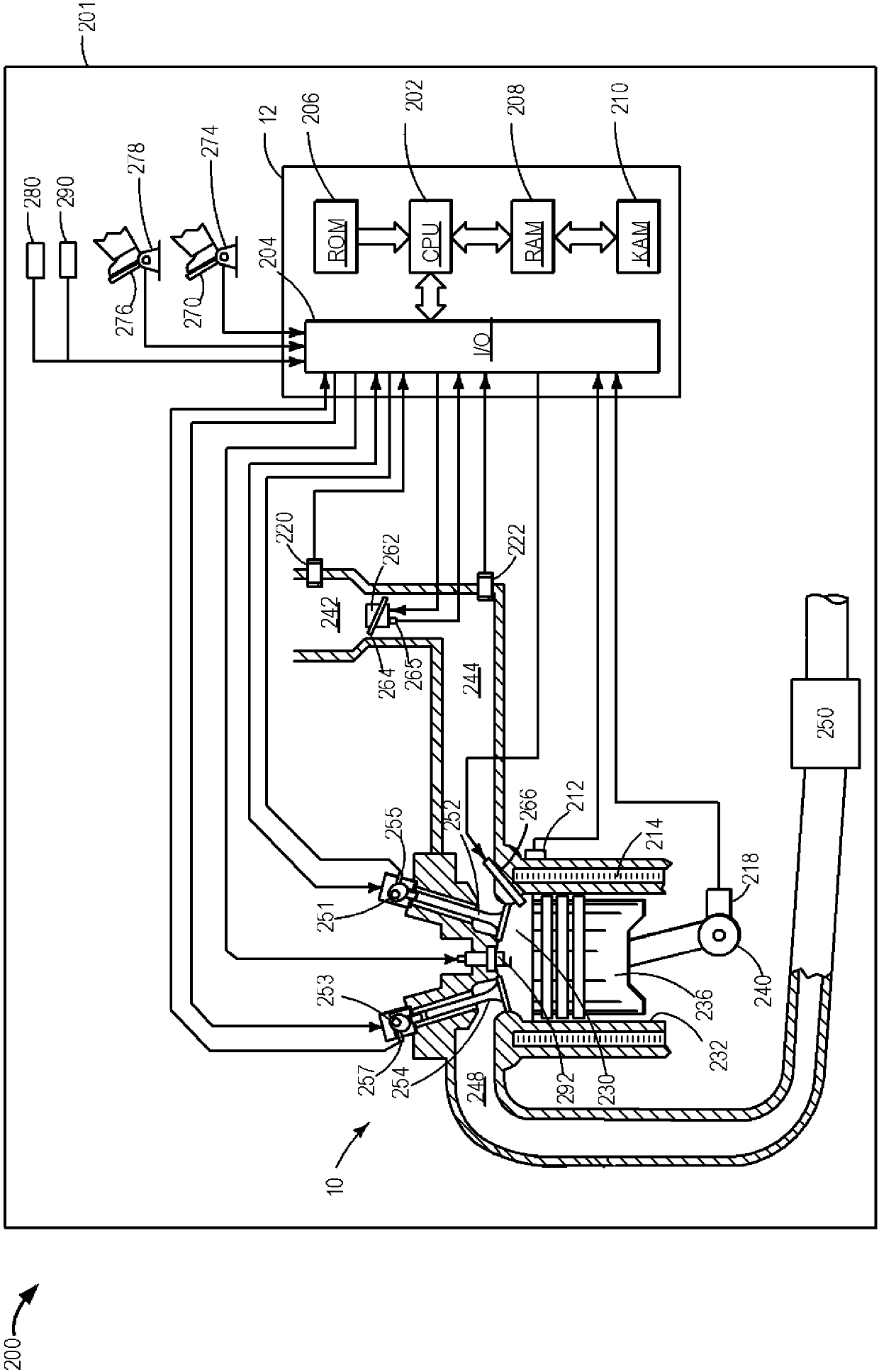

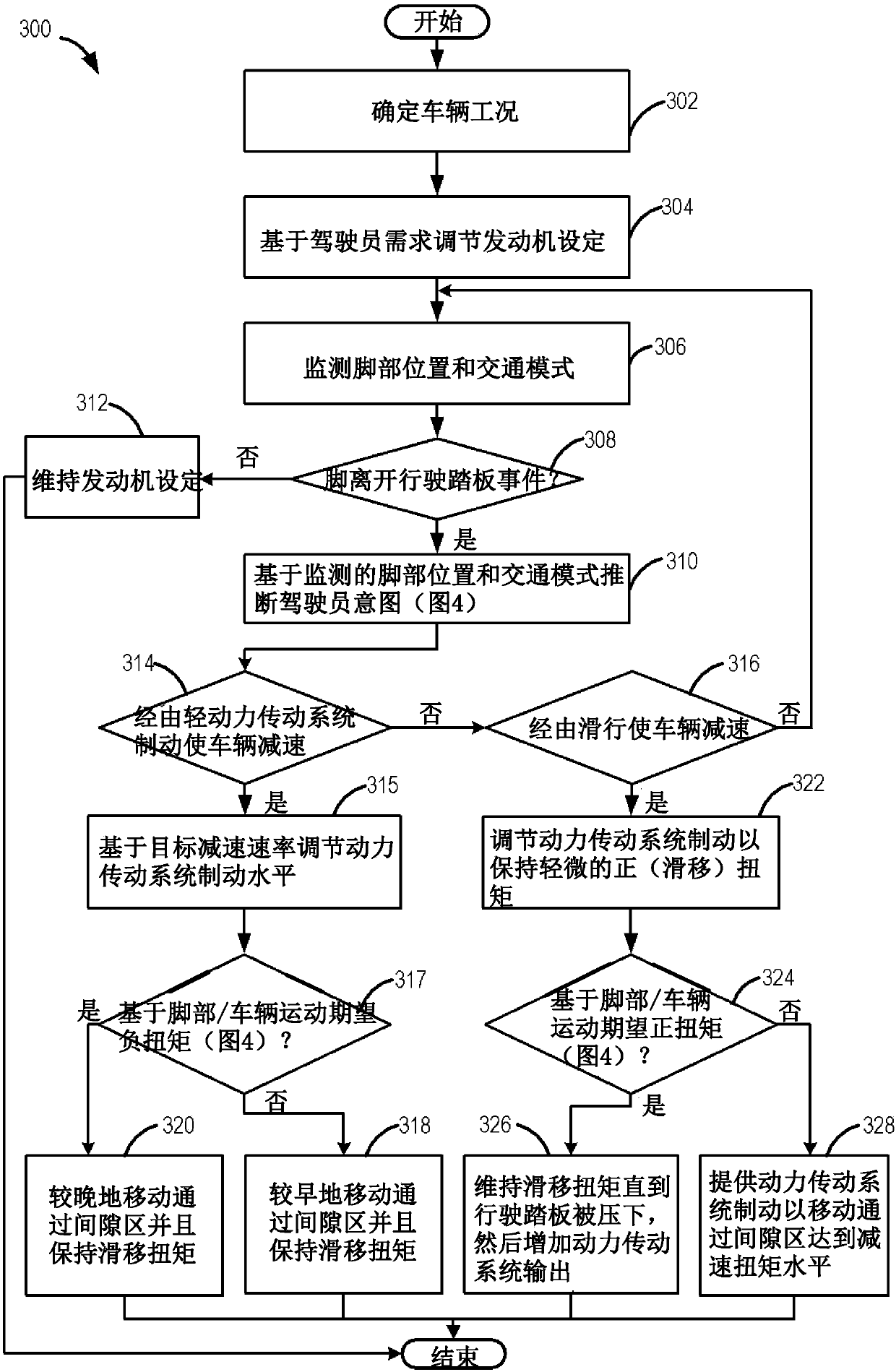

[0014] The following description refers to methods for managing systems coupled to the engine such as figure 1 in the vehicle system figure 2 Systems and methods for clearance in a vehicle driveline of an engine system of an engine system. The method provides an improved method of adjusting driveline torque based on operator foot movements captured by foot cameras inside the vehicle and traffic patterns captured by cameras looking outside the vehicle. The controller can be configured to perform tasks such as image 3 A control routine of an exemplary routine for adjusting torque in a vehicle driveline based on driver intent. as reference Figure 4 As described, the controller may infer driver intent based on operator foot movements captured by foot cameras inside the vehicle and traffic movement outside the vehicle. Figure 5 Exemplary graphical outputs illustrating driveline lash adjustments in a vehicle based on predicted driver intent are shown. By utilizing the syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com