Low-density vehicle polypropylene composite resin composition

A composite resin, polypropylene technology, applied in the field of automotive materials, can solve the problems of increasing the proportion of materials and increasing the difficulty of lightweighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the examples.

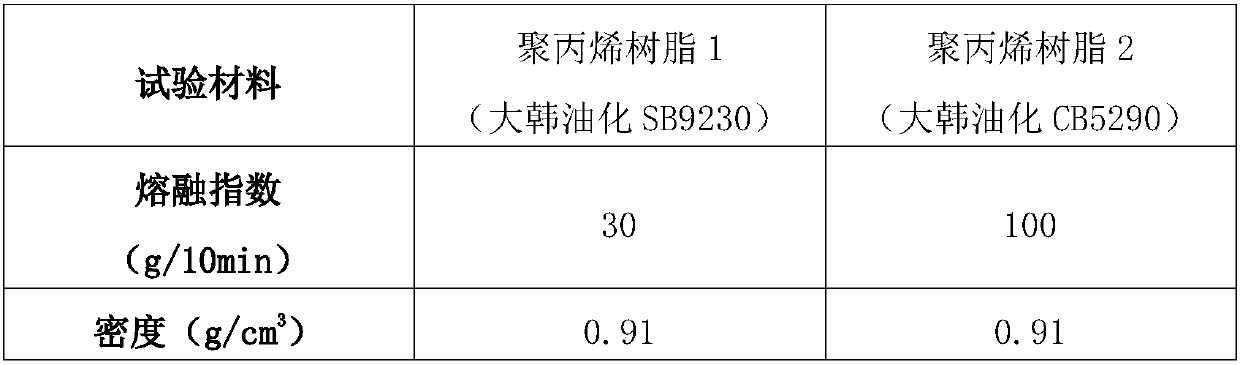

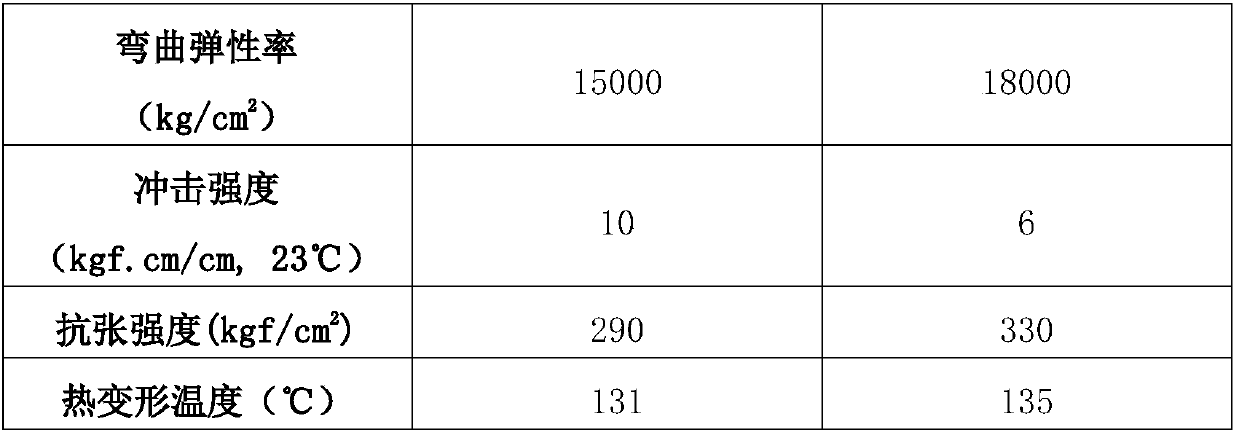

[0027] A low-density polypropylene composite resin composition for automobiles, the material components of which include high-crystalline polypropylene, a reinforcing agent, and an impact modifier. The weight percentage of any composition in the material component is:

[0028] 30wt% to 75wt% of high crystalline polypropylene with an isotactic index of more than 96%,

[0029] 10wt%~35wt% reinforcing agent,

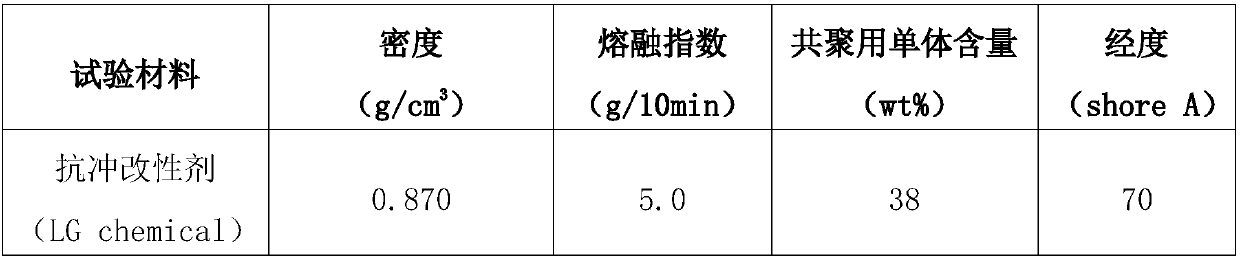

[0030] 15wt% to 35wt% impact modifier.

[0031] The reinforcing agent is selected from the reinforcing agent comprising hollow microspheres, and the weight ratio of the hollow microspheres and the reinforcing agent after mixing is 1:1~1:10, preferably 1:3~1:10 or 1:5~1: 10 is appropriate. If the content of hollow microspheres in the reinforcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com