Method for identifying anisotropic plasticity parameters of plate based on single-cone indentation

A technology of anisotropy and plastic parameters, applied in the direction of testing material hardness, etc., can solve problems such as the influence of sheet metal precision plastic forming, and achieve the effect of accurate experimental results and simple experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] This embodiment is a method for identifying anisotropic plastic parameters of sheet metal based on single-cone pressing.

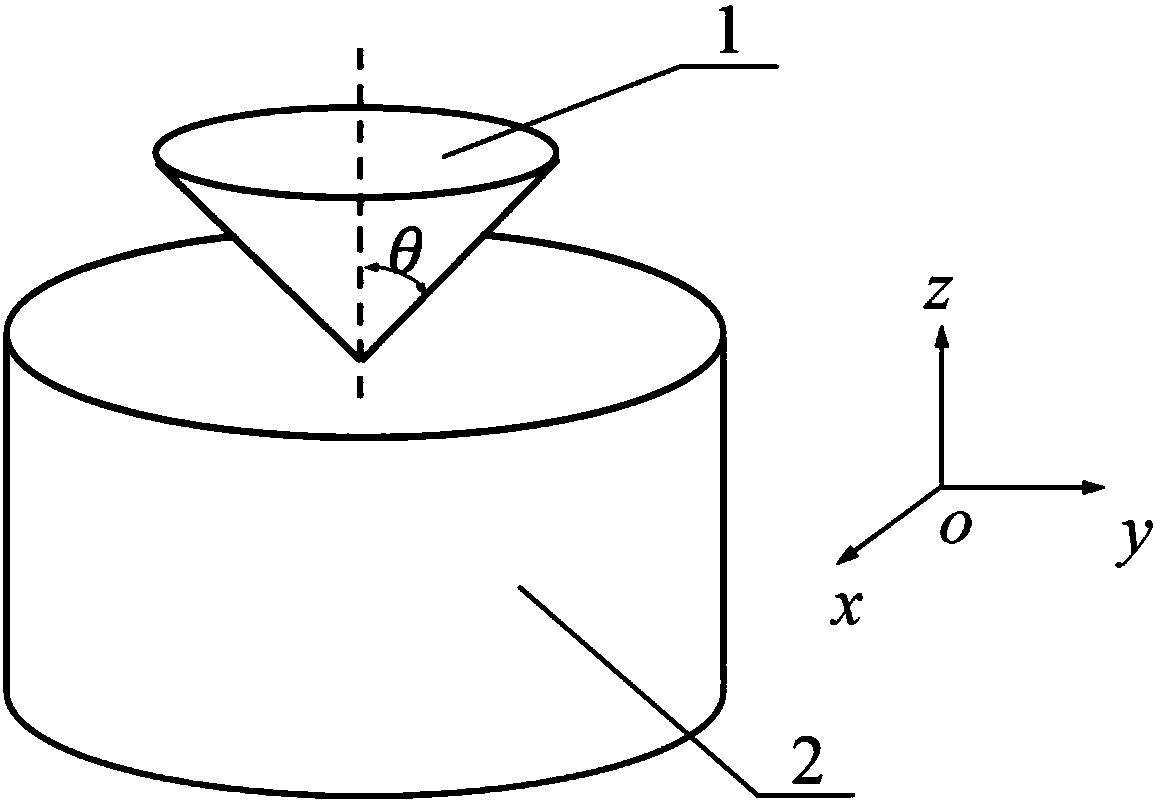

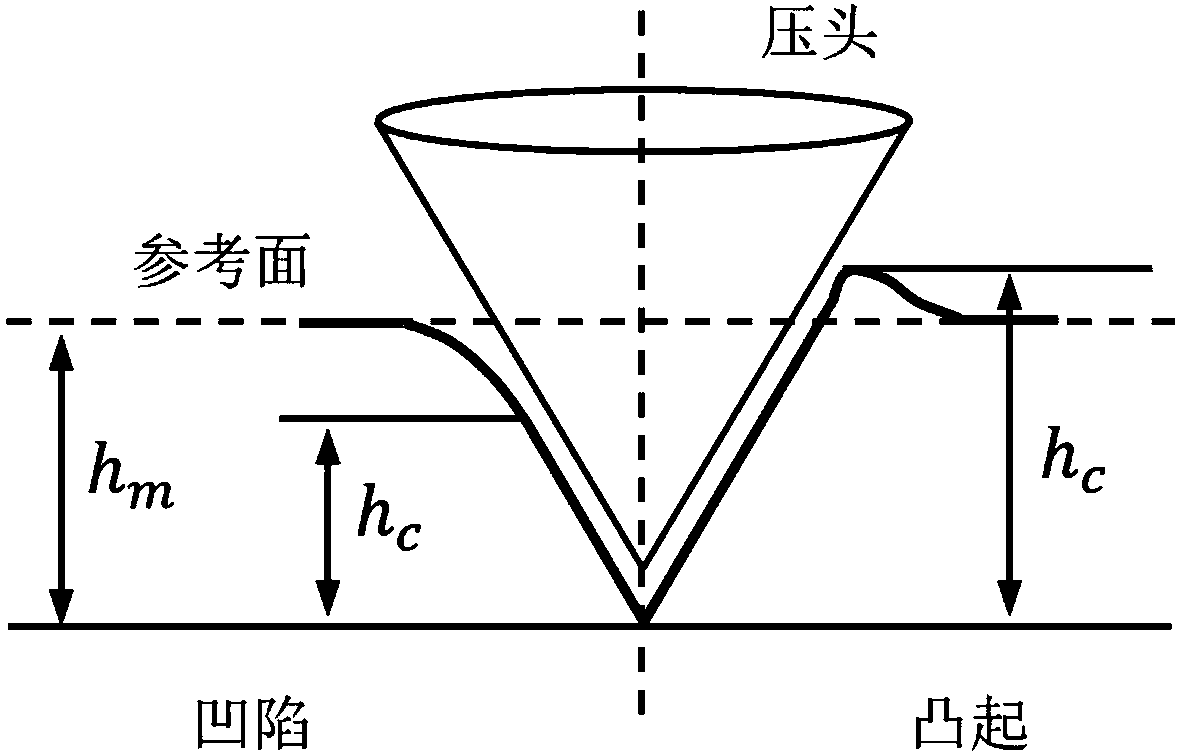

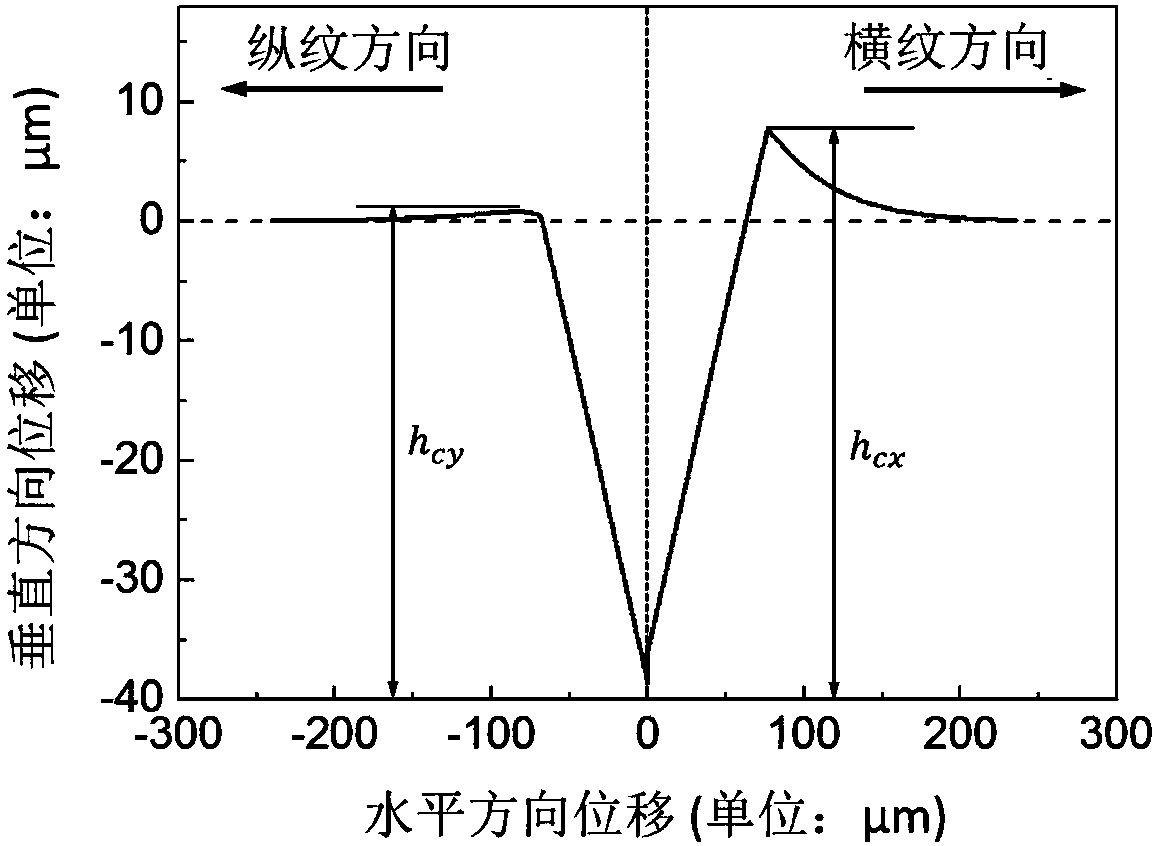

[0037] refer to Figure 1 to Figure 7 , this embodiment is based on a single-cone press-in method for identifying anisotropic plastic parameters of sheet metal, which is applied to micro-nano testing and hardness testing equipment; combined with three-dimensional confocal imaging equipment, small-sized test pieces and materials are realized. bit test. The material response information obtained through the indentation test can directly calculate the anisotropic plastic parameters of the tested material.

[0038] Step 1. Select a conical indenter with an inner half angle of 60° to establish a dimensionless function model

[0039]Using the Π theory of dimensional analysis, the relationship between the response parameters of the load-displacement curve of single-cone indentation, the response parameters of unloading residual indentation morphology and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com