In-situ shale brittleness test device and method based on acoustic emission technique

An acoustic emission technology and brittleness test technology, which is applied in the field of in-situ shale brittleness test devices based on acoustic emission technology, can solve the problem of inability to obtain shale acoustic emission characteristic parameters and stress-strain data synchronously, and acoustic emission characteristics cannot be obtained synchronously Parameters and stress-strain data, reducing the accuracy of rock brittleness index measurement, etc., to improve the evaluation accuracy, avoid errors, and facilitate experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

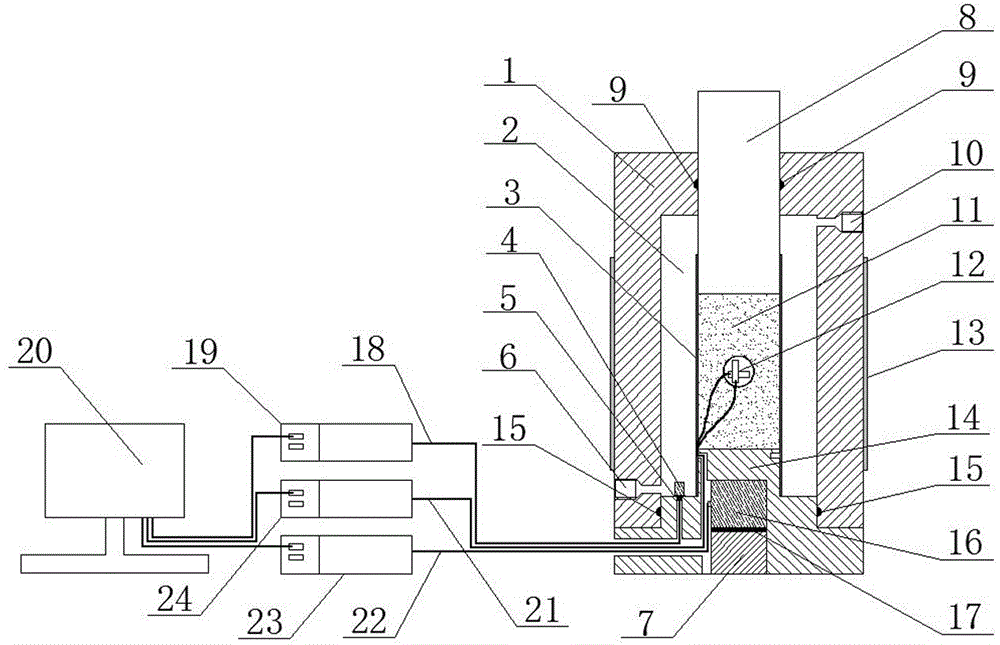

[0030] Such as figure 1 As shown, an in-situ shale brittleness test device based on acoustic emission technology of the present invention includes: a triaxial autoclave 1, a base 14, a piston rod 8, an acoustic emission sensor 16, a temperature sensor 4, a strain gauge 12, an electromagnetic Heating ring 13.

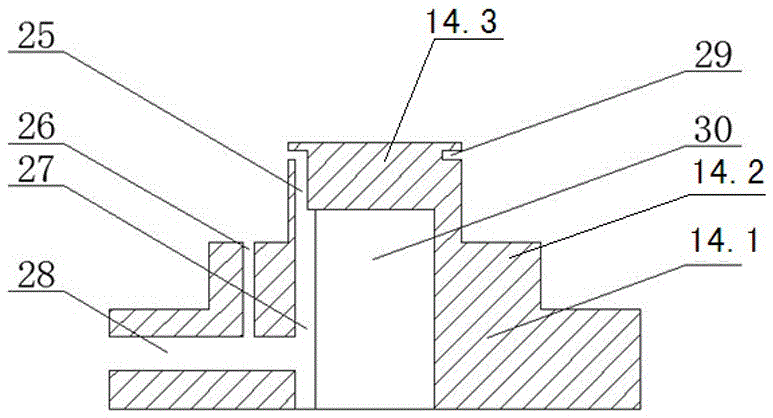

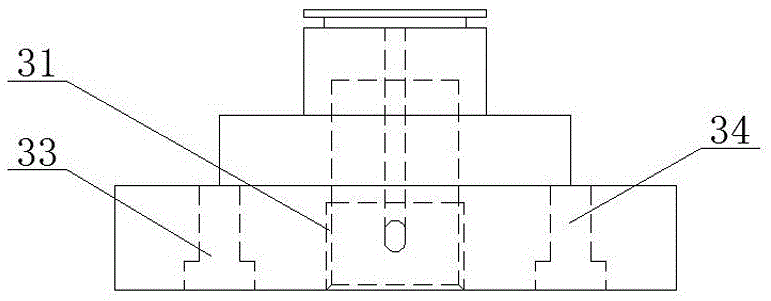

[0031]The piston rod 8 is mounted on the upper end of the triaxial autoclave 1 and sealed with a sealing ring I9, which can be used to apply pressure to the rock core 11; the base 14 is installed at the lower end of the triaxial autoclave 1, sealed with a sealing ring II15, and passed through the screw Hole I33, screw hole II34, screw hole III32, and screw hole IV35 are fixed; the rock core 11 is placed between the piston rod 8 and the base 14, and sealed with a thermoplastic tube 3; the liquid injection port 6 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com