Periodic structure grooving circular pipe longitudinal-radial vibration conversion underwater acoustic transducer and transduction method

A technology of underwater acoustic transducer and periodic structure, which is applied to transducers, sounding equipment, instruments and other directions used underwater, can solve the problem of large size of low-frequency transducers, and achieve the effect of reducing vibration frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

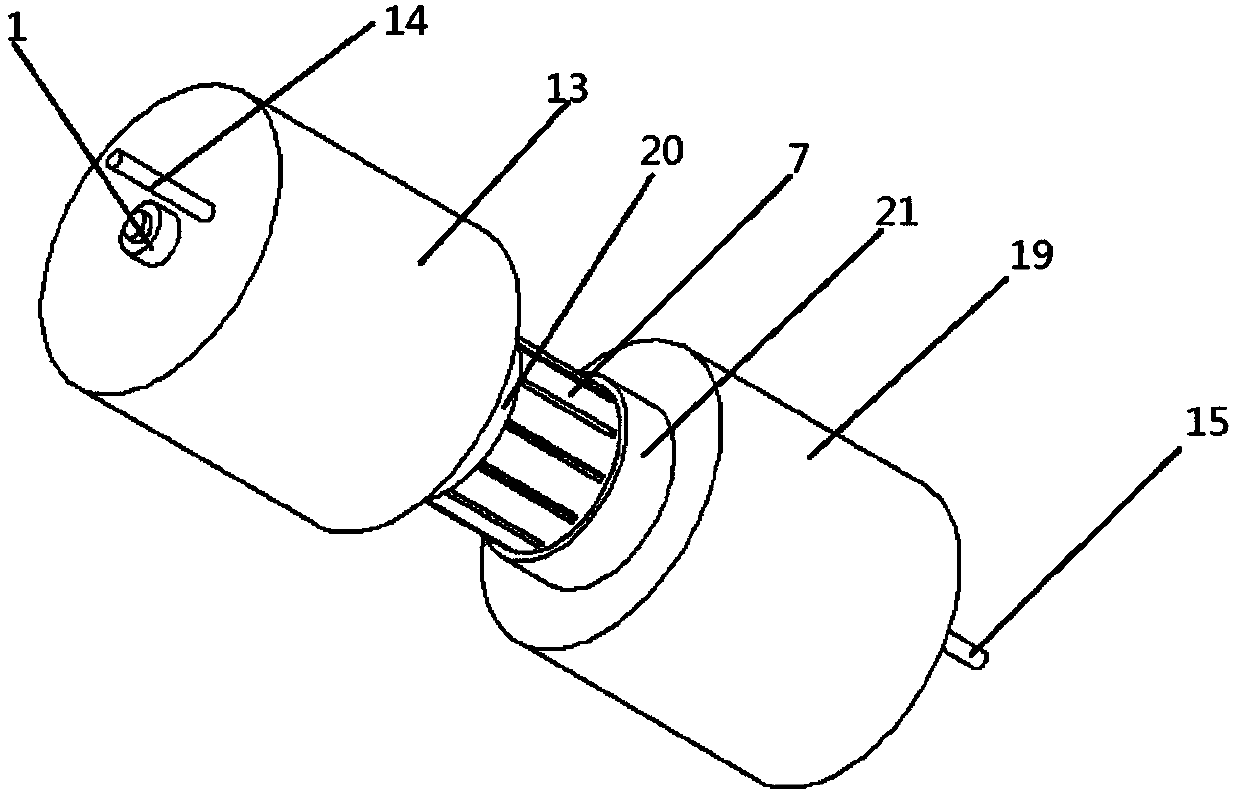

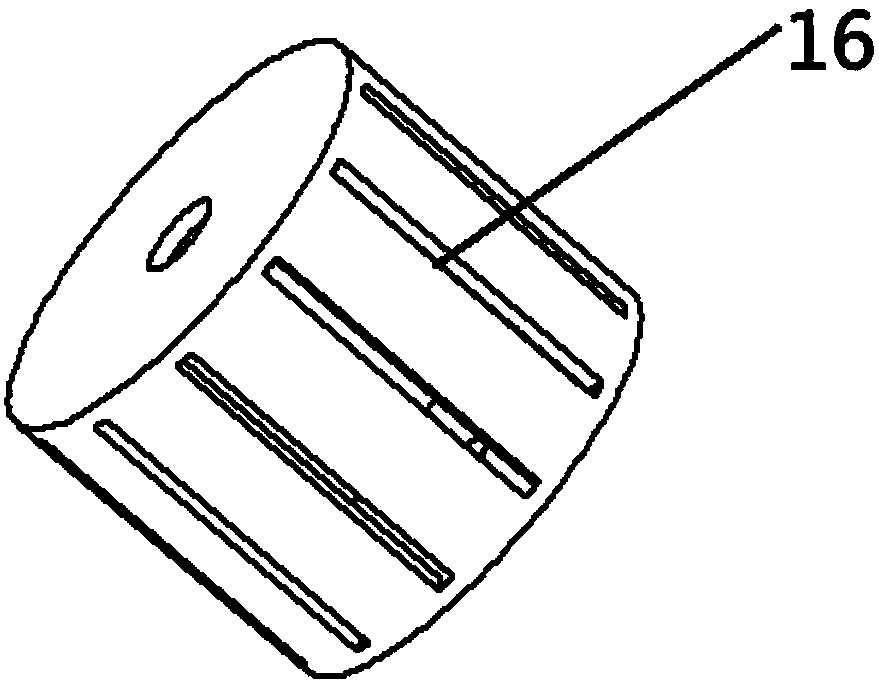

[0034] Embodiment 1: The longitudinal-diameter vibration conversion underwater acoustic transducer of the periodic structure slotted circular tube of the present invention, such as figure 1 As shown, the transducer includes a screw rod 2, and a left end waterproof cable 14, a left end rear cover plate 13, a left end longitudinal vibration excitation unit 20, a slotted circular tube 7, a right end longitudinal vibration excitation unit 21, and a right end Rear cover plate 19 and right end waterproof cable 15.

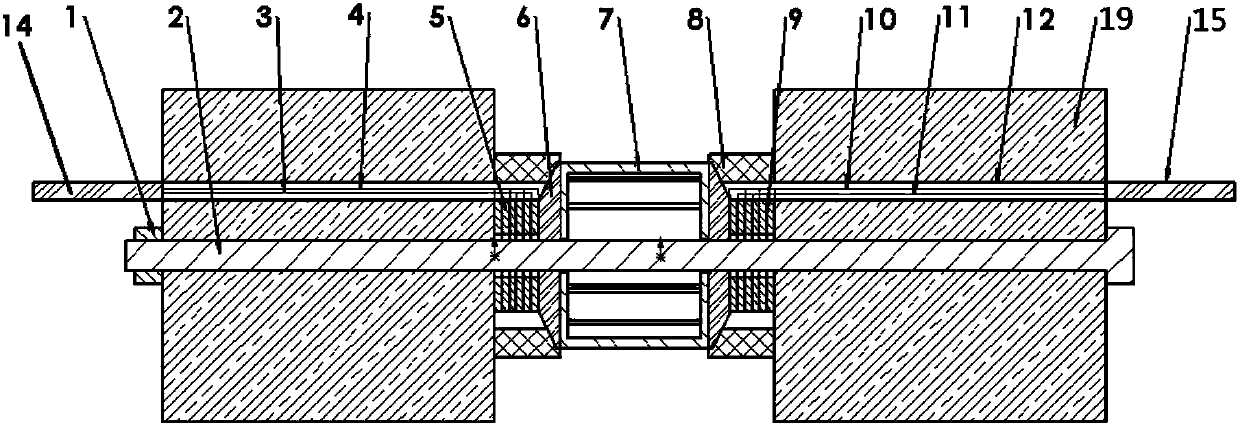

[0035] Such as figure 2 As shown, the longitudinal vibration excitation unit 20 at the left end includes a sealing sleeve 8, a piezoelectric ceramic stack 5 installed on the screw 2 and a trumpet-shaped front cover 6, the sealing sleeve 8 is set on the piezoelectric ceramic stack 5, and the piezoelectric ceramic stack 5 and the sealing sleeve 8 are located between the left end rear cover 13 and the trumpet-shaped front cover 6, the piezoelectric ceramic stack 5 is formed...

Embodiment 2

[0037] Embodiment 2: as Figure 4 As shown, on the structure of Embodiment 1, an intermediate longitudinal vibration excitation unit and a slotted circular tube are added, and the intermediate longitudinal vibration excitation unit 18 includes a sealing sleeve 8 and a horn-shaped front cover plate at the left end installed on the screw in turn, a piezoelectric The ceramic stack 5 and the horn-shaped front cover at the right end, and the sealing sleeve 8 are set on the piezoelectric ceramic stack, and the piezoelectric ceramic stack 5 and the sealing sleeve 8 are both located between the horn-shaped front cover at the left end and the horn-shaped front cover at the right end. The electric ceramic stack 5 is made of piezoelectric ceramic sheets and electrode sheets 9, and both ends of the piezoelectric ceramic stack 5 are electrode sheets 9. From left to right, the electrode sheets at odd positions are connected to the negative electrode lead , the electrode sheets at the even p...

Embodiment 3

[0038] Embodiment 3: as Figure 5 , on the structure of Example 1, two intermediate longitudinal vibration excitation units and two slotted circular tubes are added.

[0039] When the overall height of the transducer is 512mm and the maximum diameter is 150mm, the characteristic frequency of the underwater model can reach 880Hz. When adding a group of slotted circular tubes and piezoelectric ceramic stacks (that is, the structure of Embodiment 2), the characteristic frequency of the underwater model can be reduced to 630 Hz. When adding two groups of slotted circular tubes and piezoelectric ceramic stacks (that is, the structure of Embodiment 3), the characteristic frequency of the underwater model can be reduced to 520 Hz. However, the frequency range of the TVR flat area of ordinary low-frequency transducers is narrow, so this periodic structure can greatly reduce the characteristic frequency of the transducer and broaden the frequency range of stable emission in the flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com