Automatic strawberry picking device based on delta parallel mechanism

An automatic picking and moving device technology, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of strawberry fruit picking, unusable harvesting methods, complex structure, etc., and achieves easy operation and small footprint , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

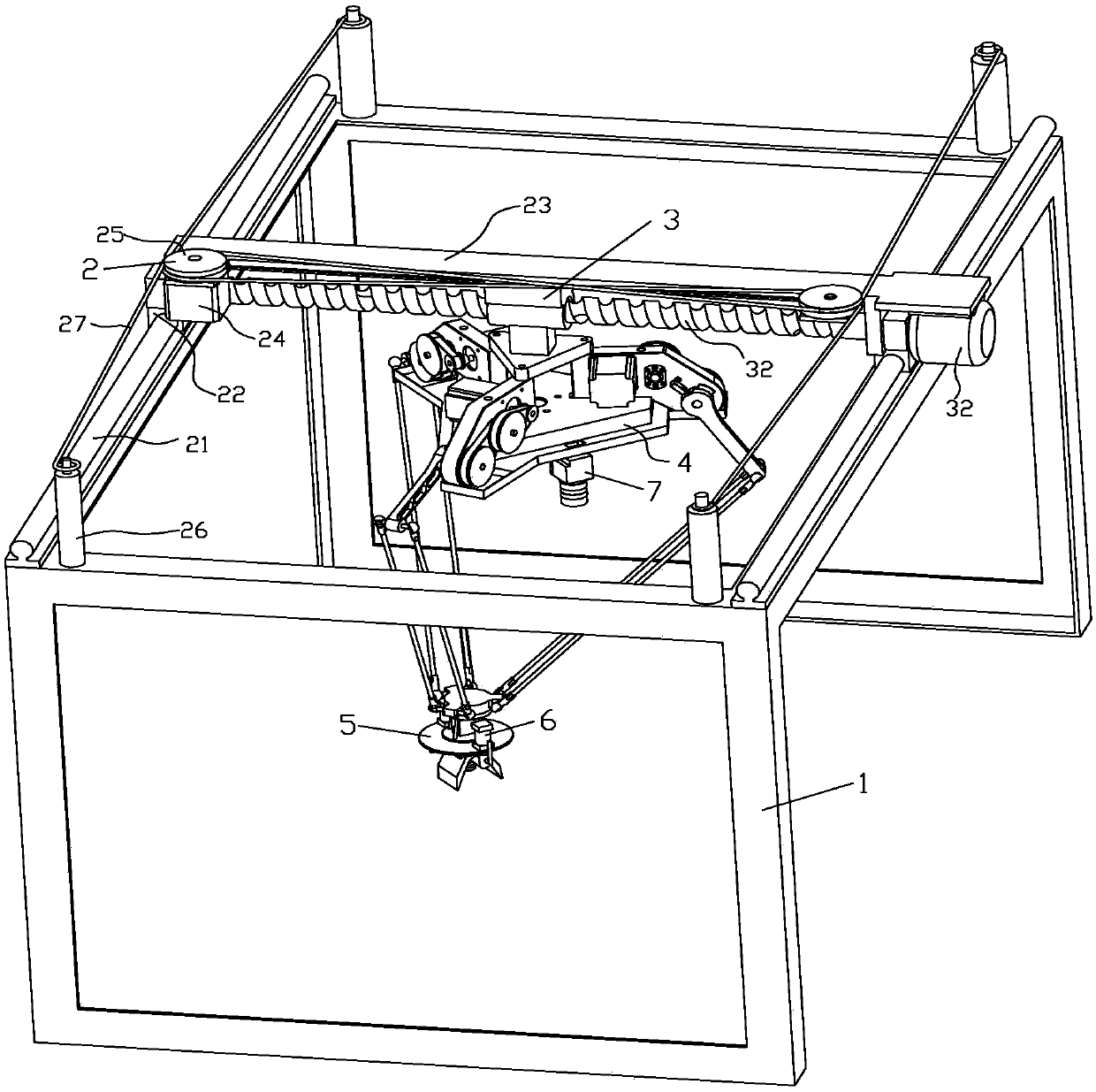

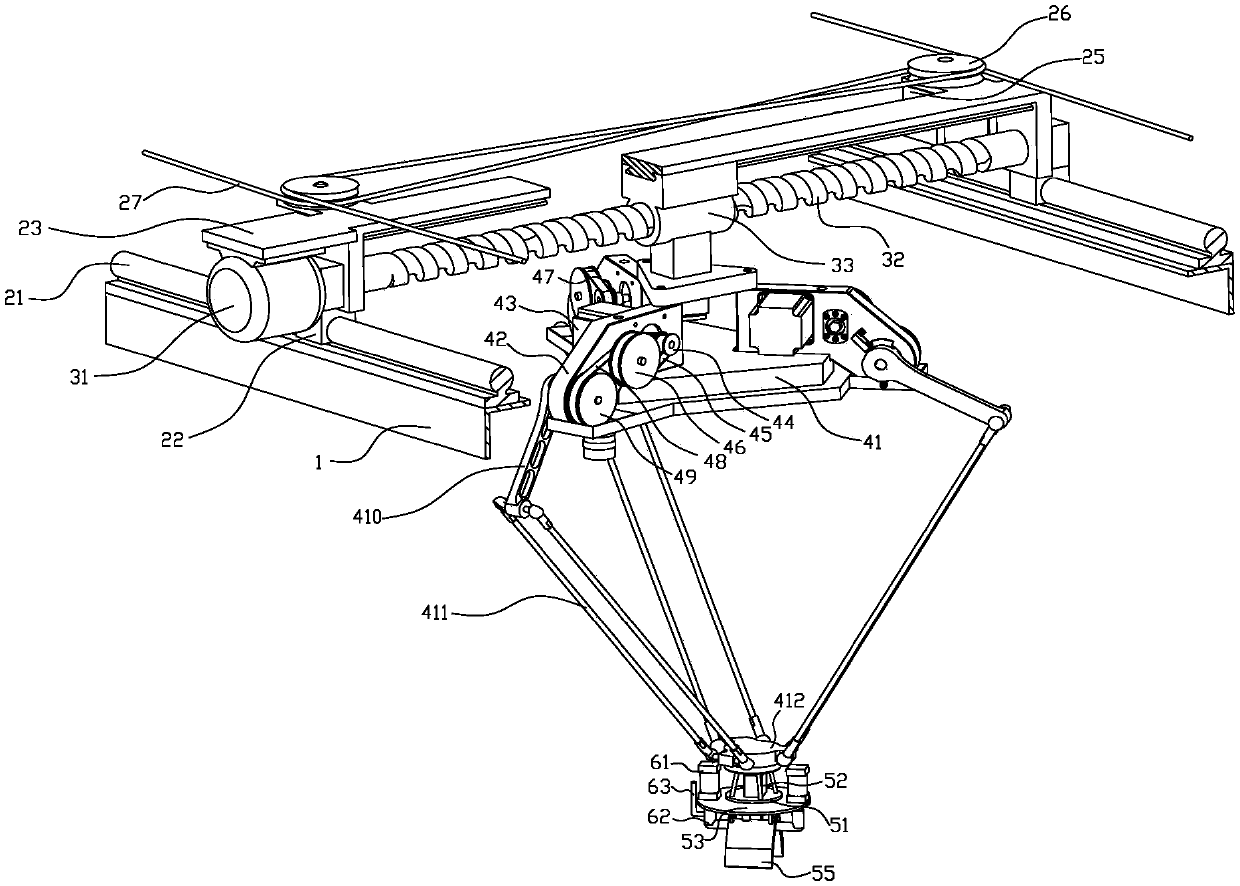

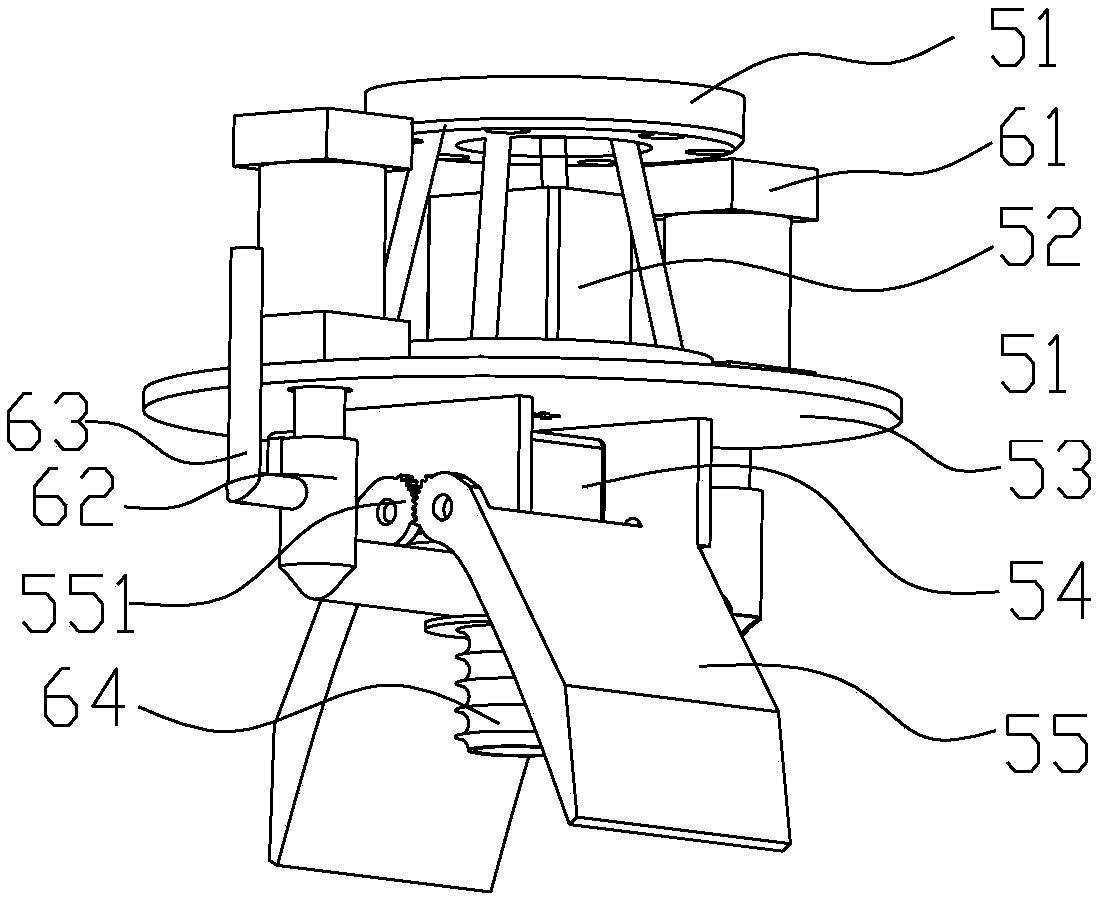

[0023] The present invention provides an automatic strawberry picking device based on a delta parallel mechanism, which is characterized in that it includes a support frame 1, a longitudinal movement device 2, a lateral movement device 3, a delta parallel mechanism 4, a picking execution device 5, an adsorption device 6 and a camera 7; wherein, the longitudinal moving device 2 and the lateral moving device 3 are located at the upper end of the support frame 1; the delta parallel mechanism 4 is located below the lateral moving device 3; the picking execution device 5 is located at the delta parallel mechanism 4 Below the moving platform 412, the adsorption device 6 is placed on the picking execution device 5.

[0024] The longitudinal moving device 2 of the present invention comprises an Ω-shaped guide rail 21, a slide block 22, a moving device supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com