Processing and measuring method of high angular accuracy infrared optical parts

A measuring method and technology of optical parts, applied in the field of optical parts processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

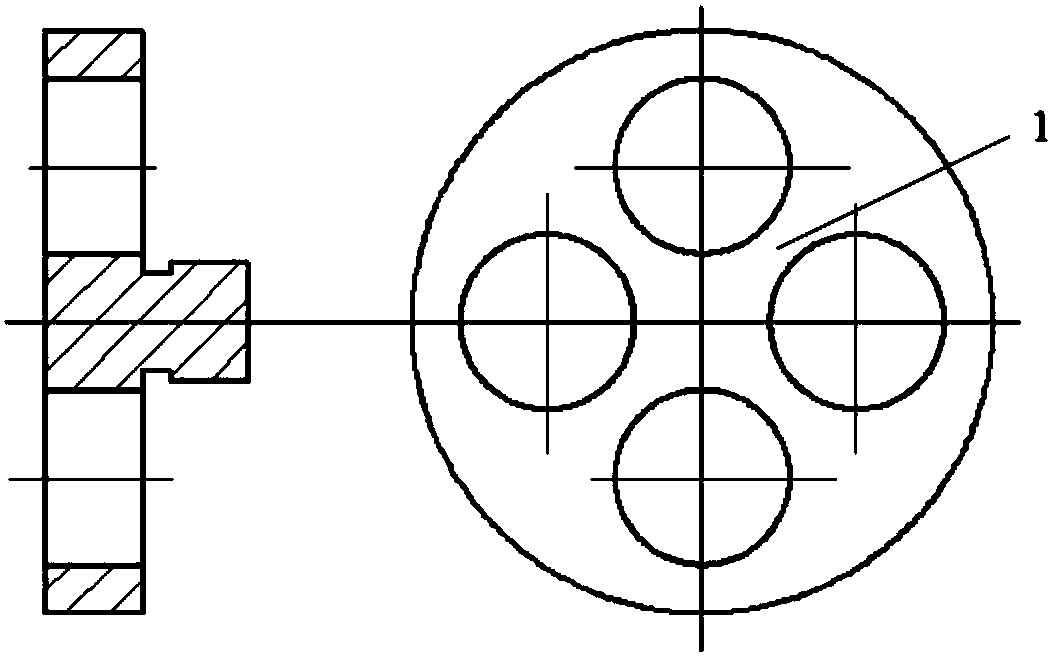

[0024] This embodiment proposes a processing and measuring method for a high-angular-precision infrared wedge prism. The processing and measuring method includes blanking, rough grinding, fine grinding, polishing, and inclination grinding in sequence; There is no special process except for controlling the size of the external margin.

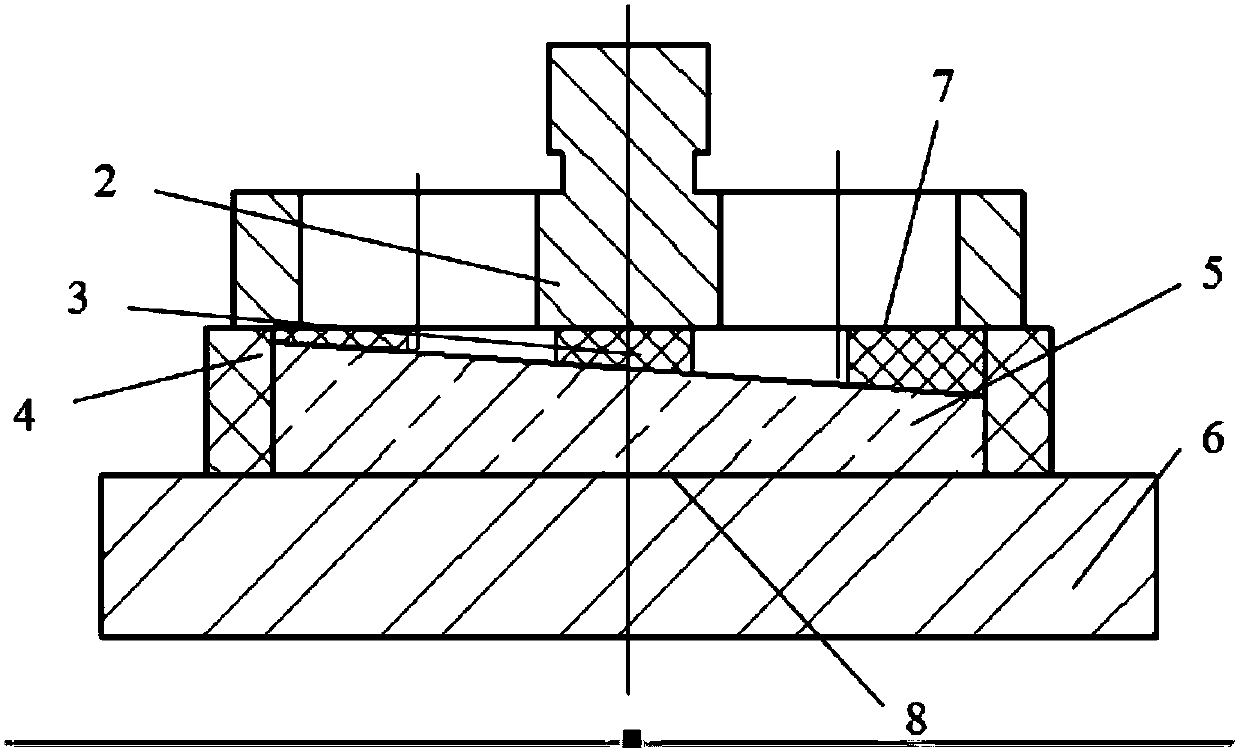

[0025] Fine grinding specifically includes: fine grinding a straight face of the wedge prism as a reference plane, processing it to aperture N=2; and then fine grinding the slope opposite to the straight face by controlling the thickness difference until the thickness difference reaches the theoretically calculated value.

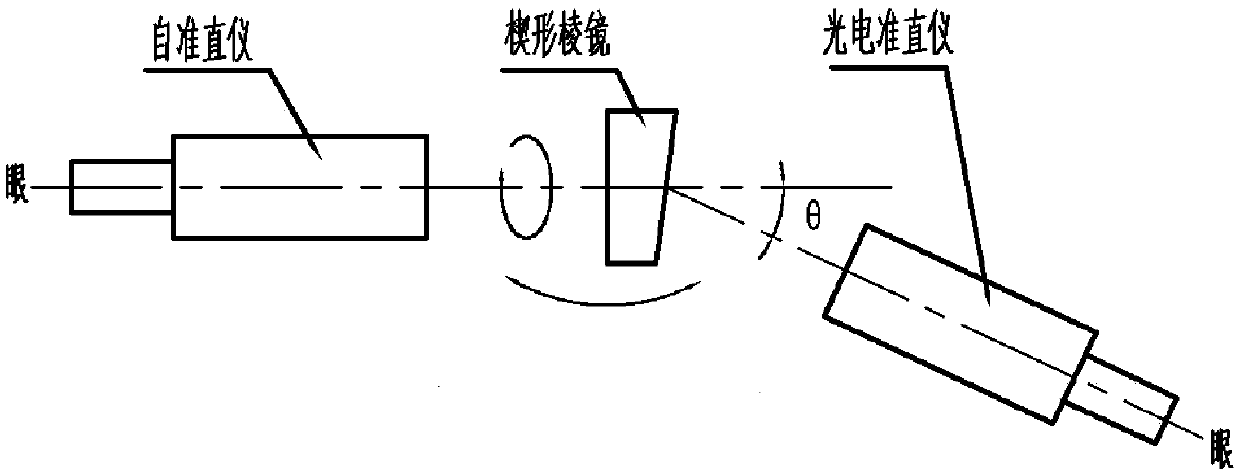

[0026] The high-precision wedge angle of ±1″ of the wedge prism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com