Production formwork for concrete prefabricated wallboard with hole and production method thereof

A prefabricated wall panel and concrete technology, applied in the direction of manufacturing tools, building components, building materials, etc., can solve problems such as wall panel cracking, wall panel impact, and increased labor, so as to speed up production progress, occupy a small area, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

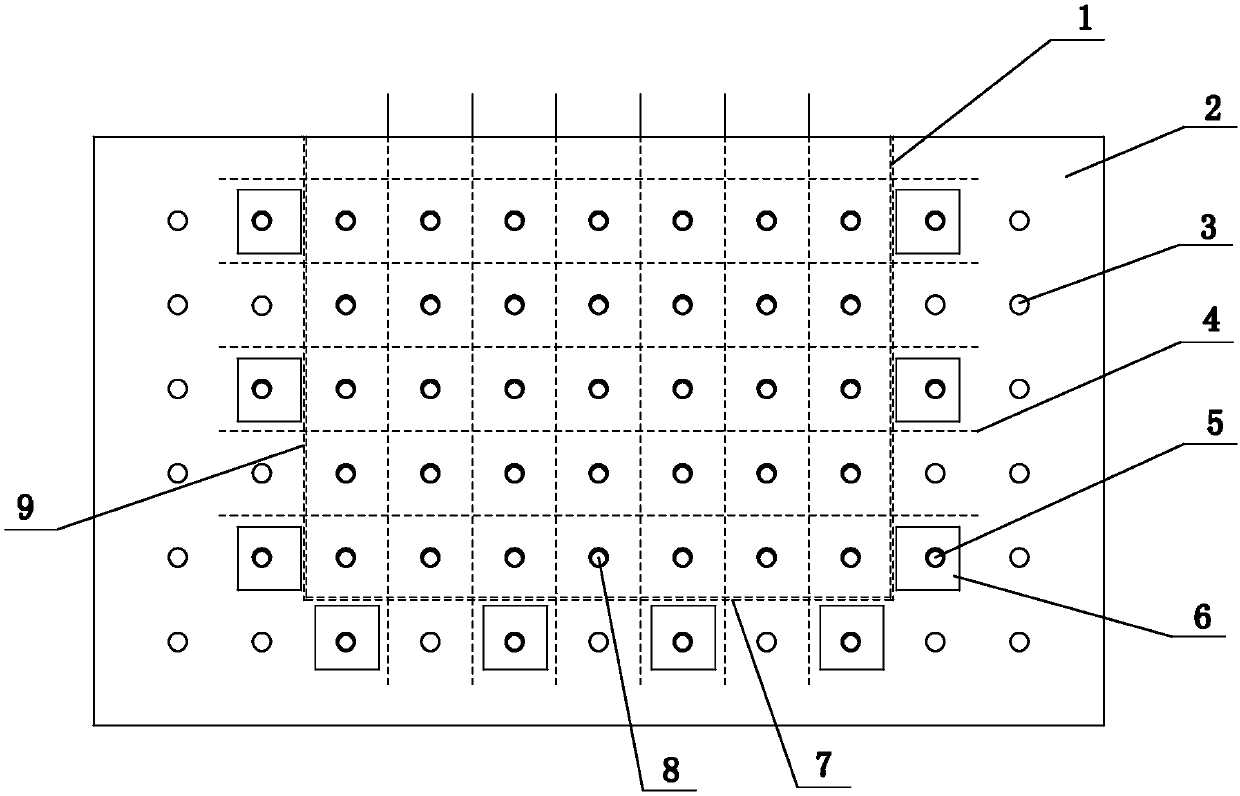

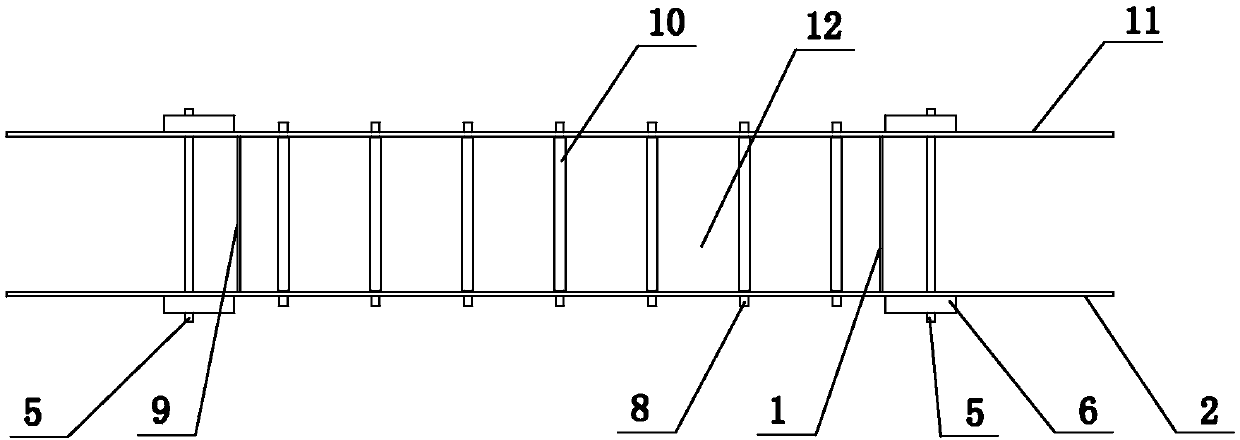

[0026] Such as figure 1 , figure 2 and image 3 The production formwork of a kind of perforated concrete prefabricated wall panel shown, it comprises front plate 2, rear plate 11, left surrounding plate 9, right surrounding plate 1, lower surrounding plate 7, several reserved pipes 10, several A positioning rod 8, several pull rods 5 and several locking heads 6.

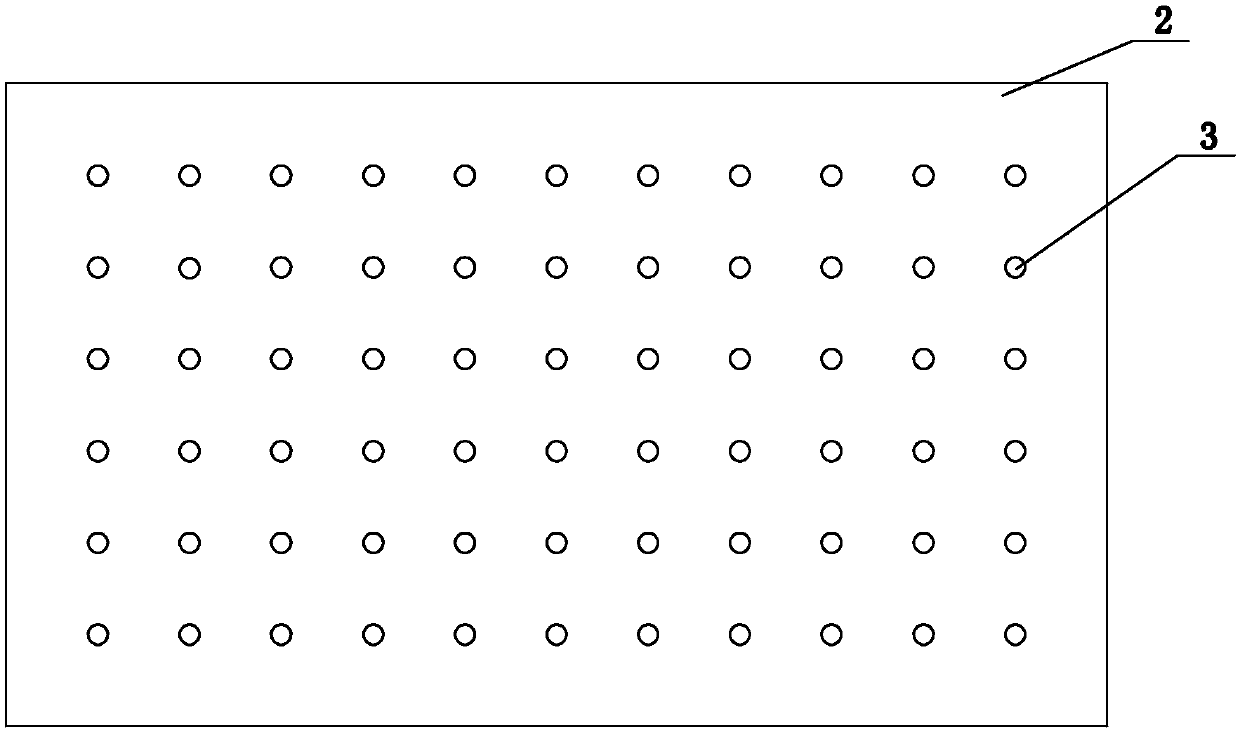

[0027] The front plate 2 and the back plate 11 are square flat plates of the same size. The front plate 2 and the back plate 11 stand on a horizontal plane one after the other. The horizontal plane can be the ground directly. The positioning holes 3 arranged vertically and regularly, the spacing between the upper and lower adjacent positioning holes 3 and the spacing between the left and right adjacent positioning holes 3 are all multiples of 100mm or 150mm or 200mm or 300mm.

[0028] A row of vertical positioning holes on the left side, a vertical row of positioning holes on the right side and a horizontal row o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com