Viscometer

A viscometer and viscosity technology, applied in the direction of flow characteristics, measuring devices, instruments, etc., can solve the problem of inaccurate measurement results, and achieve the effect of improving the scope of application, improving accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

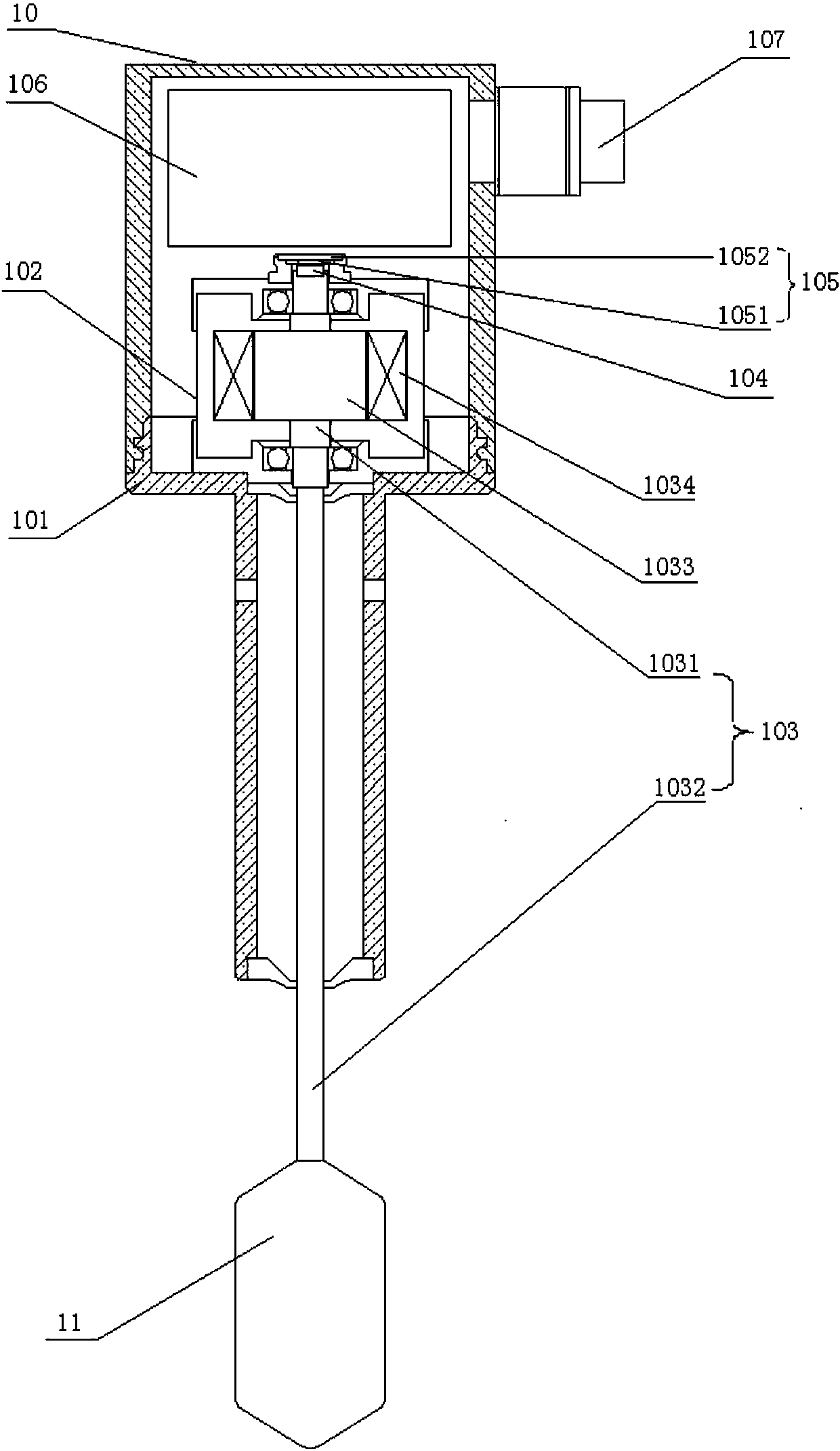

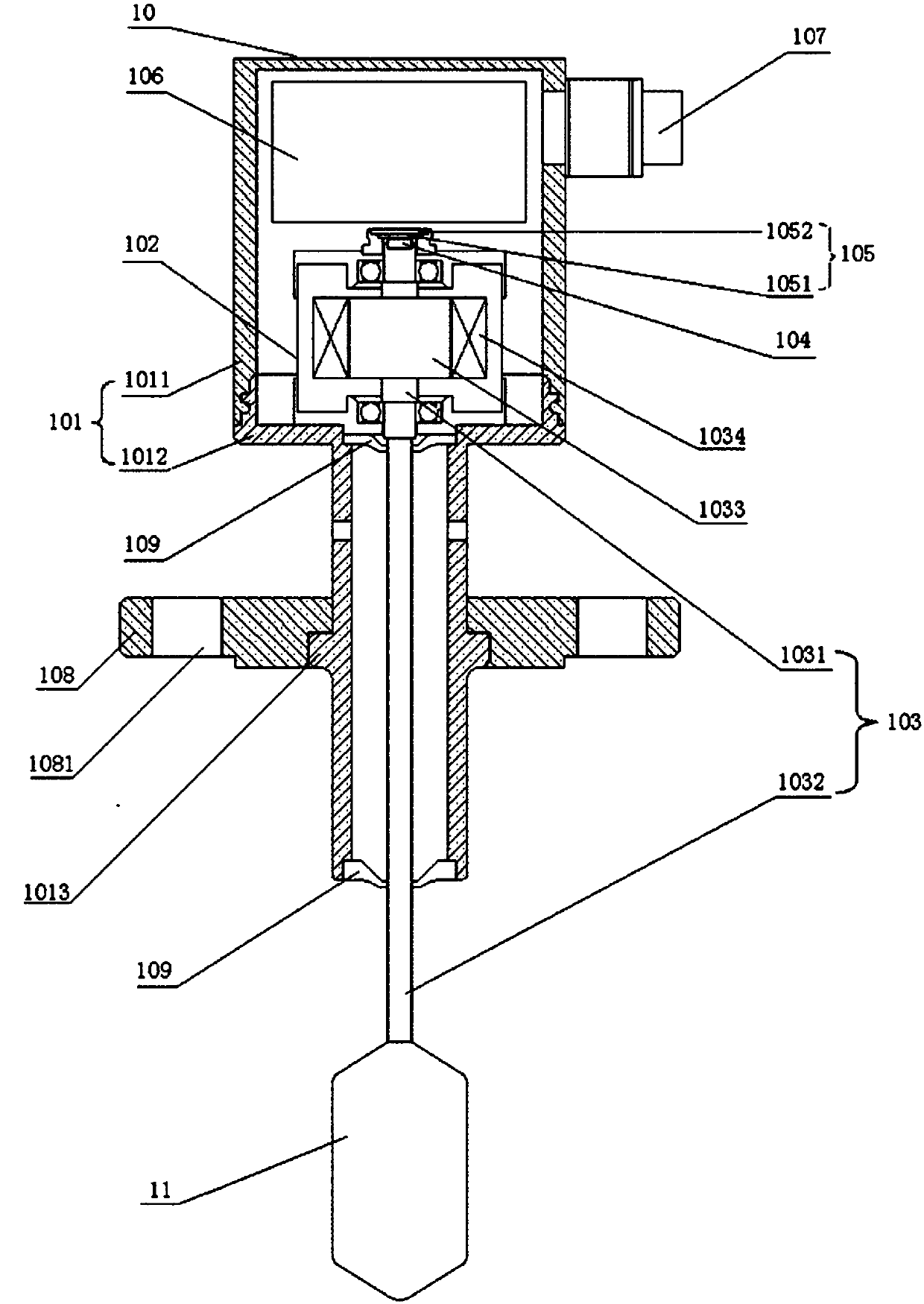

[0052] like Figure 2A As shown, the present embodiment provides a viscometer that may include: a servo motor 10 and a viscosity sensing device 11; wherein, the servo motor 10 may include: a housing 101, a servo motor body 102, a motor shaft 103, and an encoder 105;

[0053] Specifically, the servo motor body 102 is arranged inside the casing 101, and the motor shaft 103 includes a first end 1031 and a second end 1032; the first end 1031 of the motor shaft 103 is arranged inside the servo motor body 102, and the second end of the motor shaft 103 1032 protrudes from the servo motor body 102 and is directly fixedly connected with the viscosity sensing device 11 . At the same time, the encoder 105 is arranged inside the servo motor body 102 for reading the rotation angle of the viscosity sensor device 11 fed back by the motor shaft 103 in the liquid to be measured.

[0054] The second end 1032 of the motor shaft 103 is fixedly connected with the viscosity sensing device 11 and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com