Drill bit cleaning mechanism for electric tool

A technology for cleaning mechanisms and electric tools, applied in liquid cleaning methods, dryers, cleaning methods and appliances, etc., can solve the problems of reduced service life, accelerated drill bit wear, and long time consumption, so as to reduce air-drying time, Improve work efficiency and improve cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

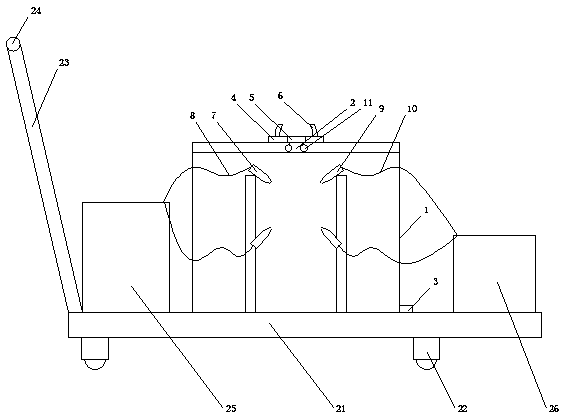

[0019] like figure 1 A drill bit cleaning mechanism for an electric tool is shown, which is used to clean the drill bit of an electric drill, including

[0020] A cleaning trolley, the cleaning trolley comprises a horizontally arranged placement platform 21, a roller 22 is provided at the bottom of the placement platform 21, and an inclined column 23 is arranged at the side end of the placement platform 21, and its inclination direction is from bottom to top. And the upper side gradually inclines to the outer end of the placing platform 21 , and a handle 24 arranged horizontally is also arranged on the upper end of the column 23 . By arranging a cleaning trolley, the movement of the cleaning box is facilitated, so that the staff can clean the drill bit anytime and anywhere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com