Wood bending machine preventing wood deformation

A technology of wood deformation and wood, which is applied in the field of wood bending equipment, can solve the problems of high stamping force, easy deformation and damage, large stamping force, wood deformation and damage, etc., and achieve reliable effect of bending wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

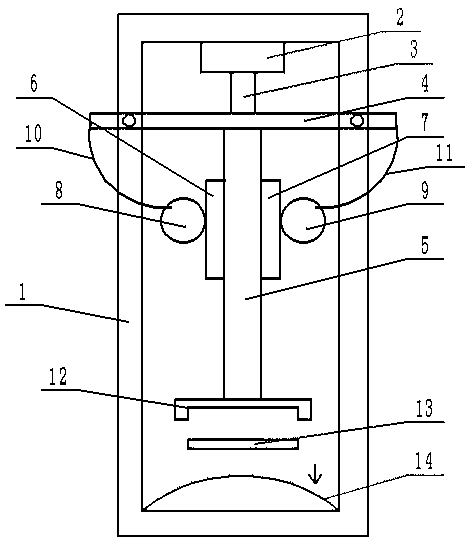

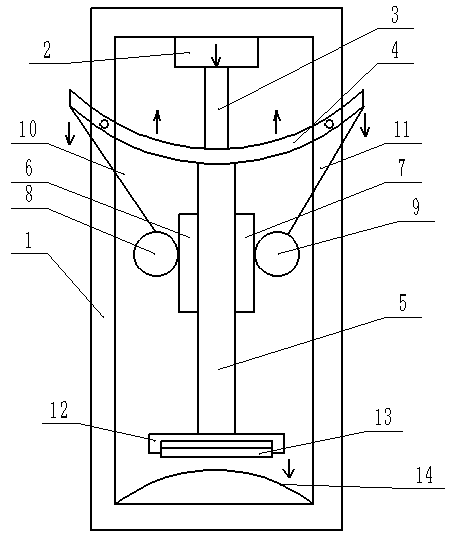

[0027] Such as figure 1 As shown, a wood bending machine for preventing wood deformation, the frame 1 is a rectangular frame, and a mold 14 is placed at the bottom of the rectangular frame, and the upper surface of the mold 14 is a curved surface. A hydraulic cylinder 2 is installed at the frame top of the rectangular frame, the cylinder body of the hydraulic cylinder 2 is connected with the rectangular frame by bolts, and the output shaft 3 of the hydraulic cylinder is vertically downward. The rectangular frame is welded below the hydraulic cylinder 2 with a horizontal bearing plate 4, which deforms when the bearing plate 4 is stressed. The material of the bearing plate 4 is preferably manganese steel plate, and the output shaft 3 of the hydraulic cylinder is perpendicular to the bearing plate 4. , the output shaft of the hydraulic cylinder is in contact with the upper surface of the bearing plate 4 when extending out. The lower surface of the bearing plate 4 is welded to th...

Embodiment 2

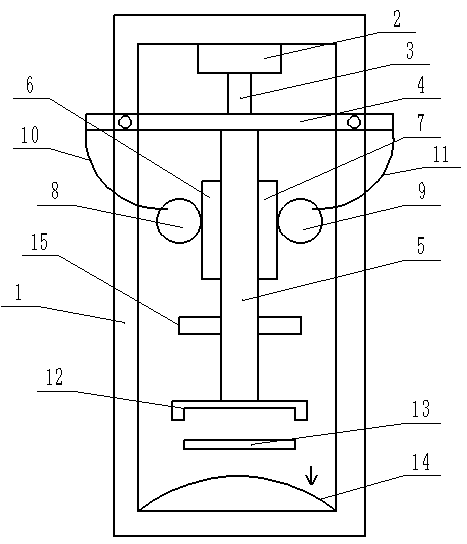

[0034] The difference between embodiment 2 and embodiment 1 is that embodiment 2 adds a steam box 15 and a steam hole 16 is opened on the clamping part 12 . Such as image 3As shown, the steam box 15 is installed symmetrically along both sides of the support rod 5 shaft, and water vapor can be sprayed out from the bottom of the steam box 15, and the steam box 15 is provided with an induction switch for controlling the spraying of water vapor. Such as Figure 5 As shown, the clamping member 12 is provided with steam holes 16 for spraying water steam, and the steam holes 16 are preferably evenly distributed.

[0035] In specific implementation, such as Figure 4 As shown, the steam source is provided by the steam box 15, and the induction switch on the steam box 15 can sense the rotation of the first gear 8 and the second gear 9. When the first gear 8 and the second gear 9 rotate, the induction switch controls Water vapor is sprayed out from the bottom of the steam box 15, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com