Two-axis four-frame stabilized platform structure

A technology for stabilizing the platform and frame, applied in the direction of using feedback control, etc., can solve the problems of large wind resistance, stable blind spot, poor aerodynamic shape, etc., achieve high space utilization, flexible installation position and method, and ensure accurate control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

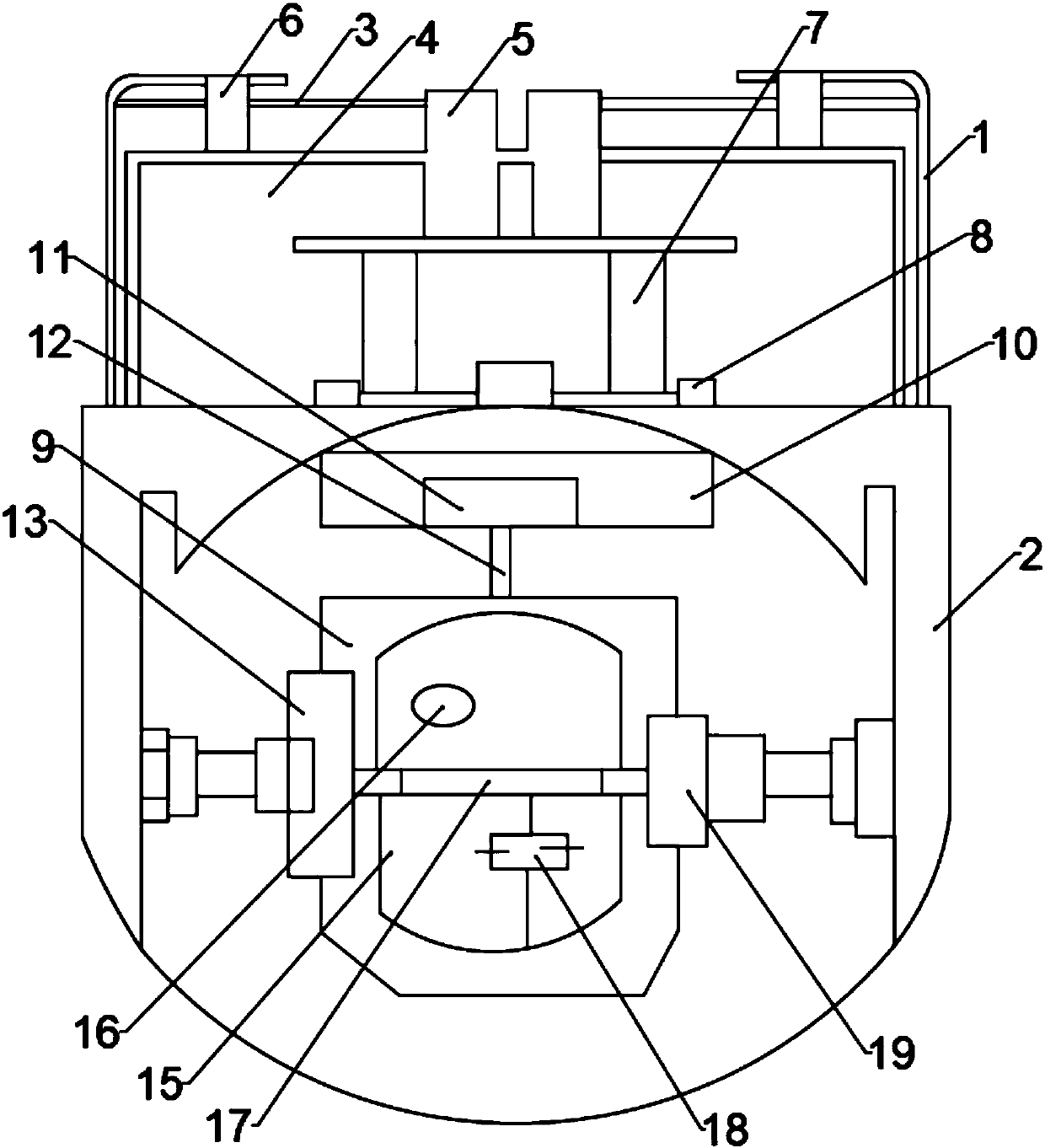

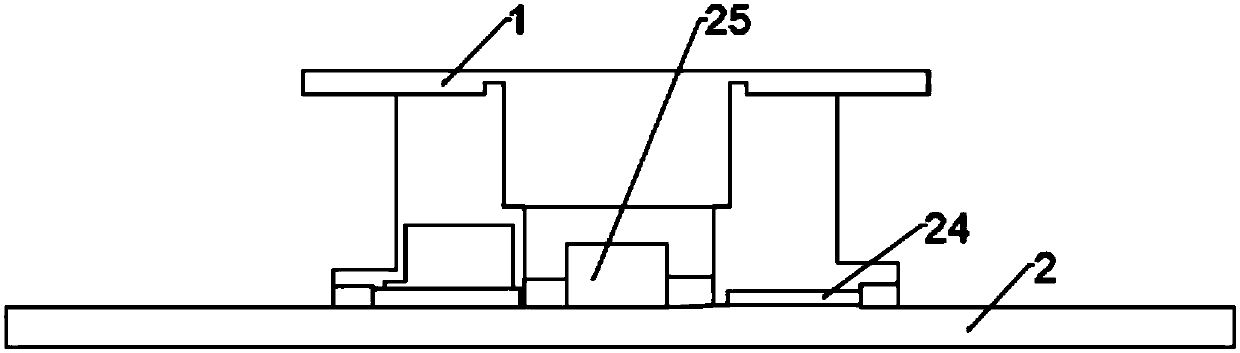

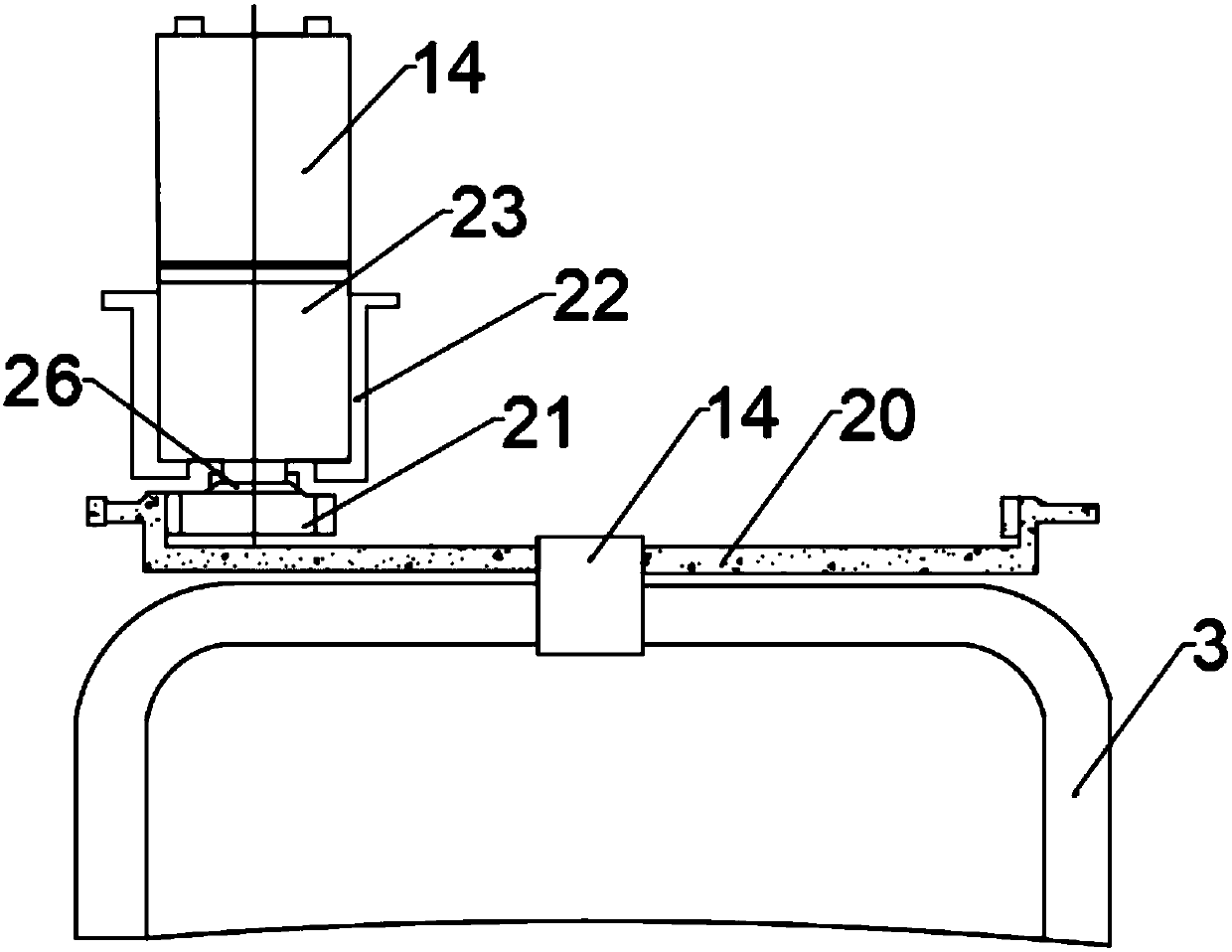

[0025] Such as figure 1 and figure 2 As shown, the present invention provides a two-axis four-frame stable platform structure, including an inner frame system 2 and an outer frame system 1, and the outer frame system 1 and the inner frame system 2 are connected by a stabilizing shaft 7, and the The outer frame system 1 includes an outer azimuth frame 3 and an outer pitch frame 4, the outer azimuth frame 3 and the outer pitch frame 4 are connected through a torque motor 5, and a transparent window 6 is also provided on the upper end of the outer azimuth frame 3, The torque motor 5 is installed on the outer surface of the outer frame system 1, the inner frame system 2 includes an inner azimuth frame 10 and an inner pitch frame 9, the inner azimuth frame 10 is arranged above the inner pitch frame 9, and the inner azimuth frame 10 and the inner pitch frame 9 are connected by an azimuth shaft 12, the top of the azimuth shaft 12 passes through the inner wall of the inner azimuth f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com