S-shaped robot joint module and S-shaped robot

A snake-shaped robot and joint module technology, applied in the field of robots, can solve the problems of many transmission links, large size of a single joint, and low positioning accuracy, and achieve the effects of high modularity, improved practicability, and good replaceability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

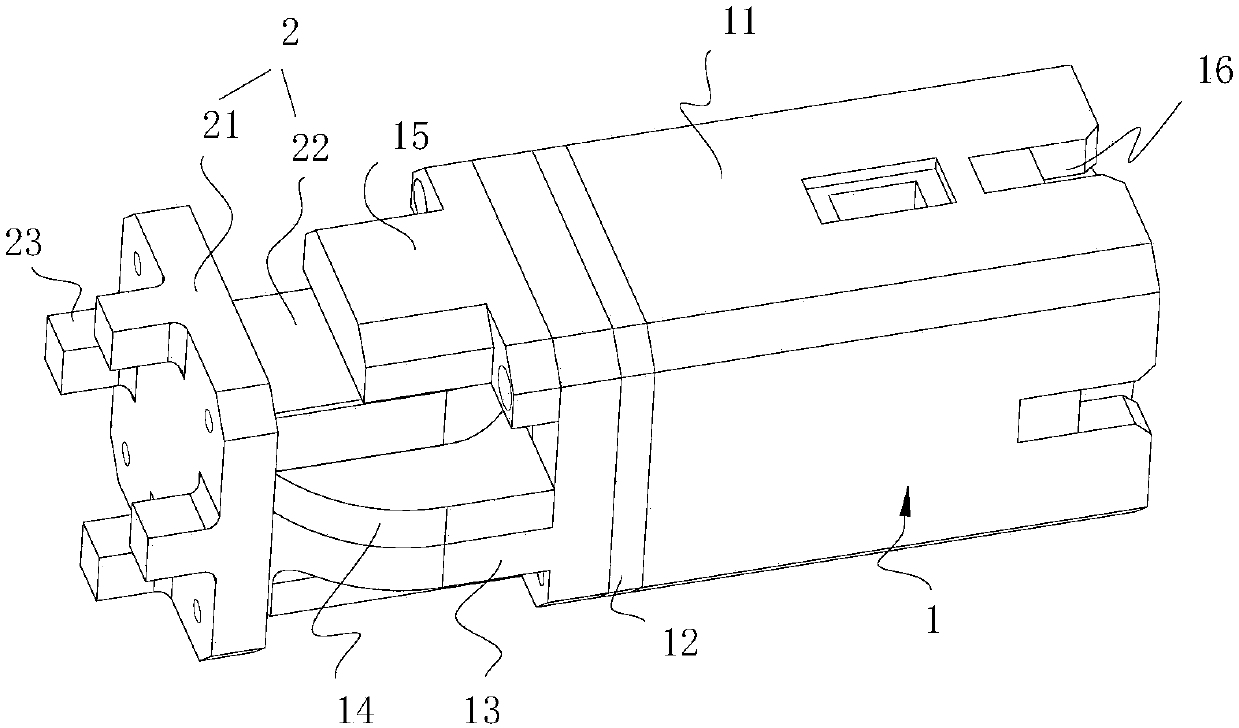

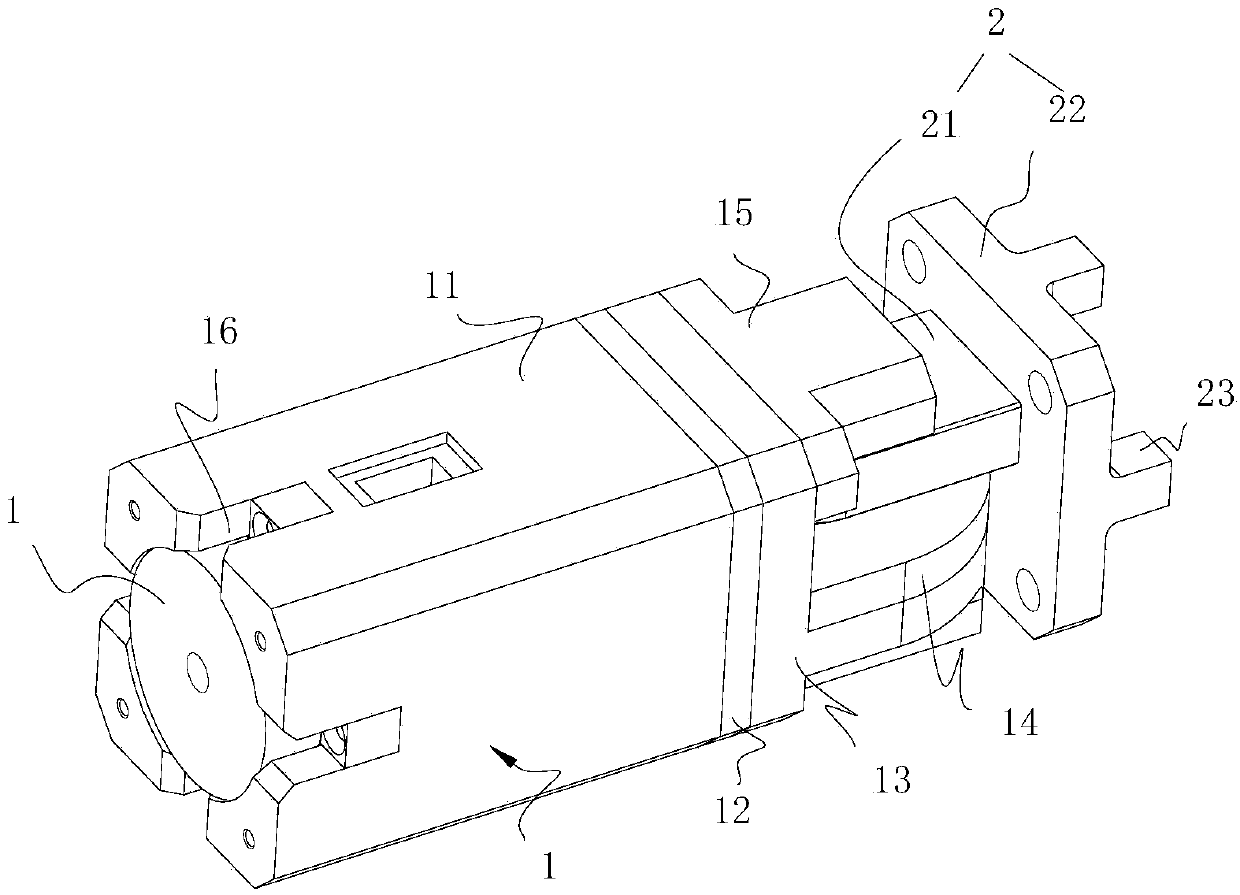

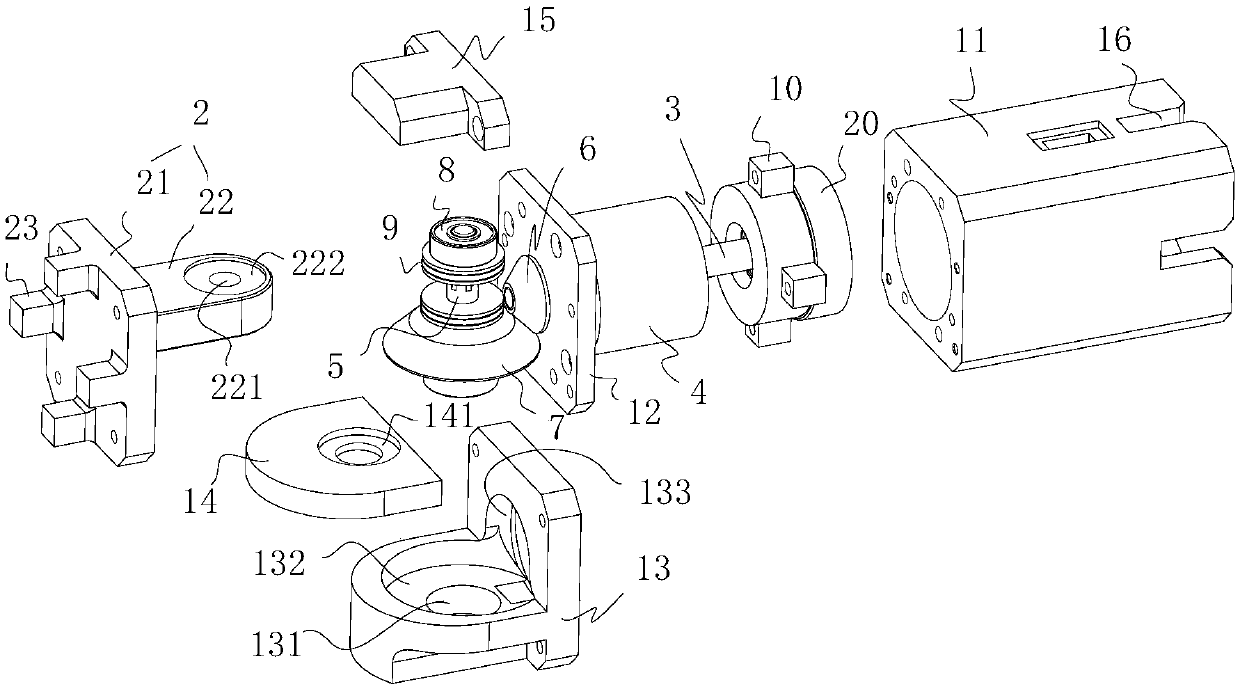

[0039] This embodiment relates to a snake-shaped robot joint module. The overall structure of the snake-shaped robot joint module includes a shell with a shell connection part at one end, and a shaft disposed in the shell is rotated. The drive unit used to drive the shaft to rotate, the rotational displacement detection unit to detect the amount of rotation of the shaft relative to the casing, and the braking force applied to the shaft to stop the rotation of the shaft relative to the casing brake unit.

[0040] The joint module of the snake robot in this embodiment further includes an articulation block with one end pivotally disposed on the casing, and a transmission unit arranged in the casing and between the shaft body and the articulation block. Among them, the transmission unit is used to realize the rotation of the shaft body to the hull of the joint connection block, and the housing connection part and the connection block connection part of the matching design are res...

Embodiment 2

[0056] This embodiment relates to a kind of snake robot, by Figure 6 As shown, it includes a mounting base 30, and a plurality of snake-shaped robot joint modules 100 connected in series connected to the mounting base 30, as in Embodiment 1. The space between adjacent snake-shaped robot joint modules 100 is The connecting part of the casing is connected with the connecting part of the connecting block, and the joint connecting block 2 of the joint module 100 of the snake robot at the outermost end is also connected with the execution module 50 . In addition, the central control module 40 connected with each snake-shaped robot joint module 100 is also arranged on the installation base 30, and in each snake-shaped robot joint module 100, the joints in the adjacent snake-shaped robot joint modules 100 The axis directions of the pivot shafts of the connecting block 2 are also arranged orthogonally.

[0057] In this embodiment, the installation base 30 and the execution module 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com