Automatic deflashing device for producing solid tire

A solid tire, automatic technology, applied in tires, applications, household appliances, etc., can solve the problems of reducing vehicle maintenance costs, heavy workload, low efficiency, etc., and achieve the effect of improving production efficiency, reducing workload, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

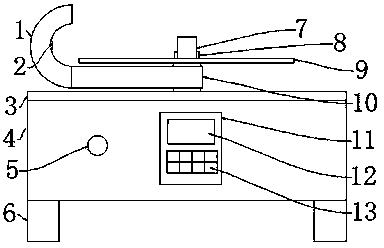

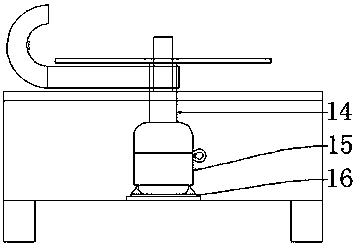

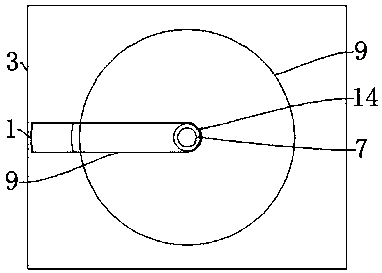

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] Such as Figure 1-Figure 3 As shown, an automatic shaving device for solid tire production includes a body 4, a support pad 6 and a motor frame 16, a support pad 6 is provided below the body 4, and the support pad 6 is used to support and fix the body 4, and the surface of the body 4 is arranged There is a buzzer 5, and the buzzer 5 is used to send out an alarm sound. A control host 11 is arranged on the side of the buzzer 5. The control host 11 is the control center of the device. The surface of the control host 11 is provided with a display screen 12. The display screen 12 It is used to display the real-time roughness value of the solid tire. A control keyboard 13 is arranged on the side of the display screen 12. The control keyboard 13 is used to send work instructions. A workbench 3 is arranged on the body 4. The workbench 3 is the workplace of the device. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com