Packing box pod for unmanned aerial vehicle logistics

A technology of drones and cargo boxes, which is applied to cargo box pods and mounted on the field of cargo box pods of drones. It can solve the problems of personnel injury, damage to drones, and loss of goods, and achieve improved automation. The degree of improvement, the effect of improving operating efficiency and reducing misoperation accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

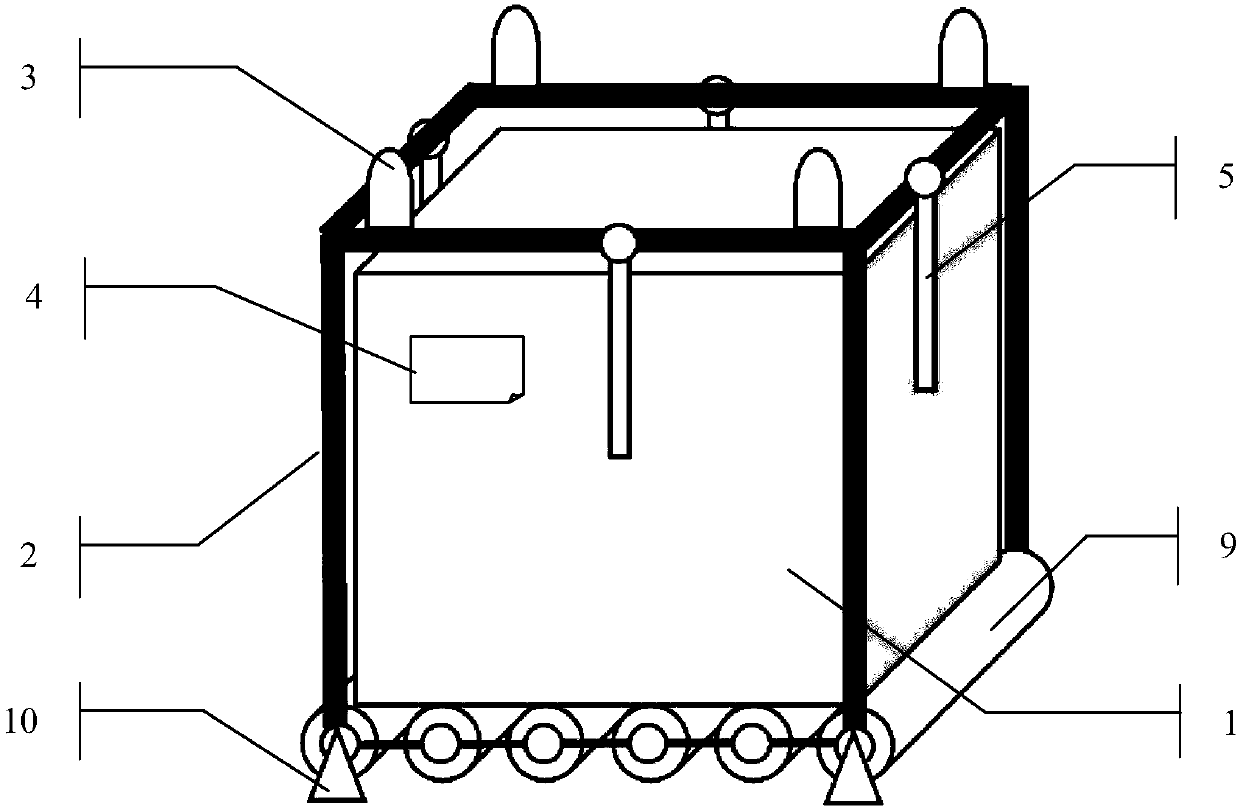

[0032] The container pod includes a container liner 1, a container shell 2, a container fixing mechanism 3, a logistics label 4, a locking mechanism 5, a communication module 6, a power supply unit 7, and a central controller 8, wherein,

[0033] The container liner 1 is used to carry the package to be transported. The container liner 1 is a square box (open at the top, with or without a cover. If there is no cover, the container shell 2 needs a top cover) ;

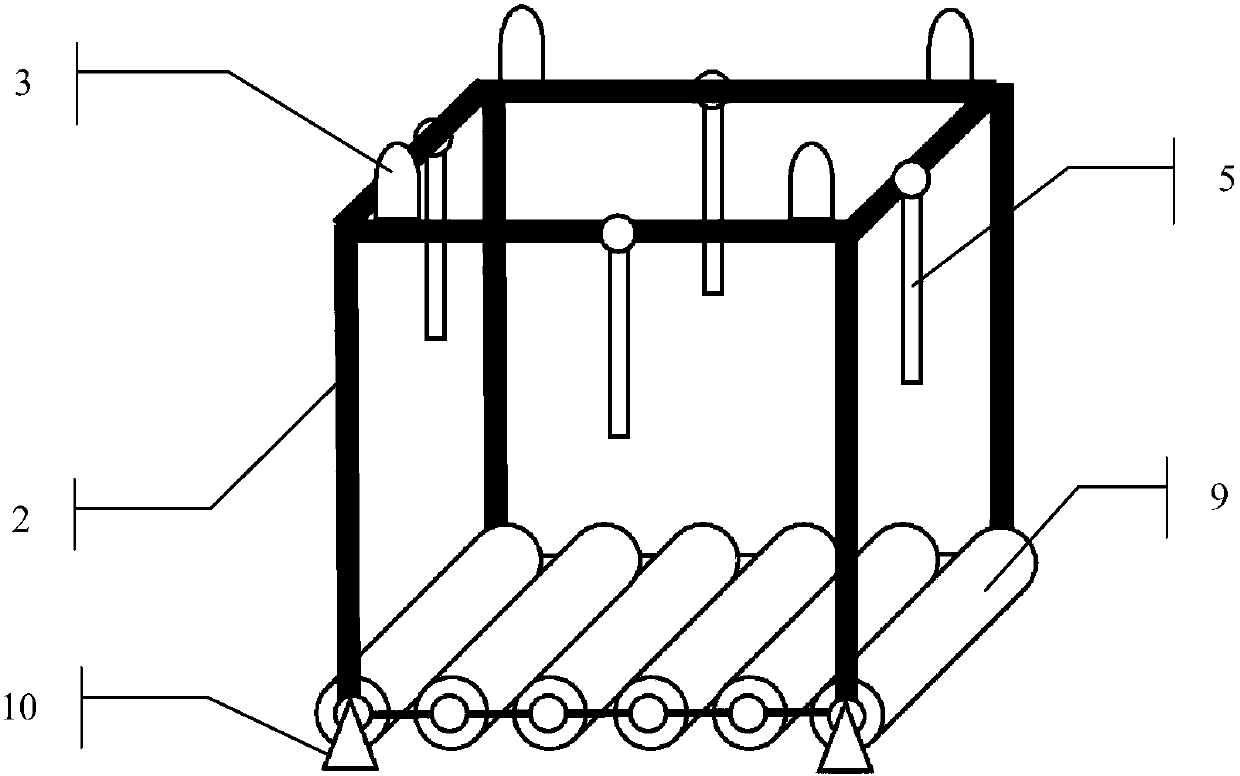

[0034] Such as figure 1 with figure 2 As shown, the container shell 2 adopts a frame structure, or it can be a frame with only a top cover, so that the container liner 1 can be pushed out after landing, and each frame is fixedly connected; the bottom surface of the container shell 2 has Rolling mechanism 9, the rolling mechanism 9 is composed of a plurality of axially parallel cylinders, used for loading and unloading the container liner 1, the axial direction of the rolling mechanism 9 is perpendicular to the directi...

Embodiment 2

[0052] like Image 6 , The container shell 2 is a square box frame structure with openings at both ends, that is, there are guard plates on both sides of the opening. The container shell 2 is provided with a window 13, and the area of the window 13 is greater than or equal to the area of the logistics label of the container liner 1, and the height of the window 13 should ensure that when the container liner 1 is installed in place, the logistics label of the container liner 1 is just from the The window 13 is exposed.

[0053] Further, a liquid crystal screen is provided on the outer surface of the container liner 1, and the electronic label is displayed on the liquid crystal screen of the container liner.

Embodiment 3

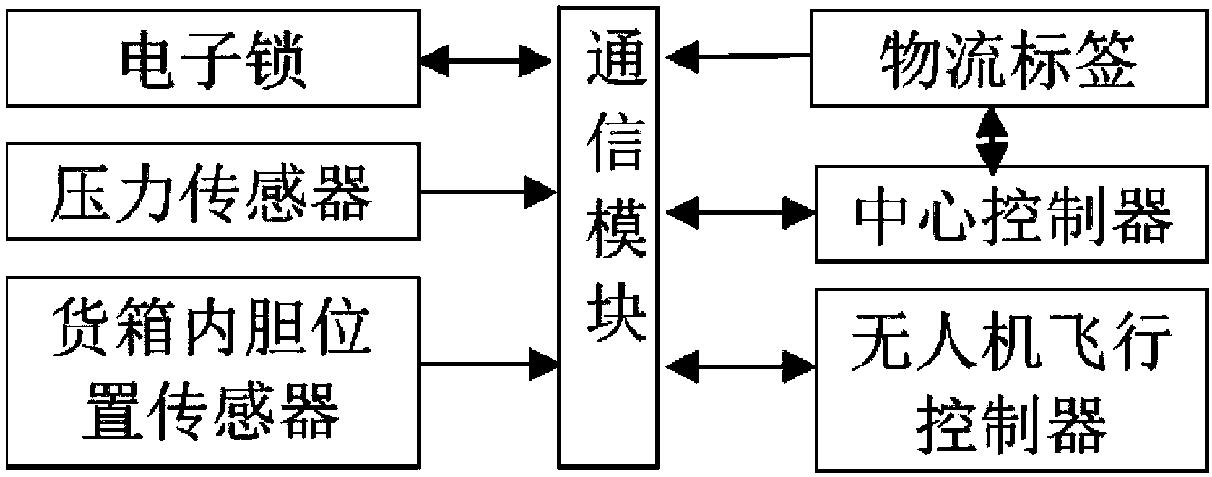

[0055] As preferably, the cargo box shell 2 of the cargo box pod also includes a cargo box liner position sensor, which is connected with the electronic lock through the communication module 6. When loading, when the cargo box liner position sensor knows that the cargo box liner 1 When it is inside the container shell 2 and has reached the predetermined position, the central controller 8 controls the electronic lock to perform a locking operation to lock the container liner 1 in the container shell 2 . See image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com