Efficient hydraulic jack

A hydraulic jack, high-efficiency technology, applied in the direction of lifting devices, etc., can solve problems such as low work efficiency, low safety, and poor working conditions, and achieve the effects of saving time, improving work efficiency, and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

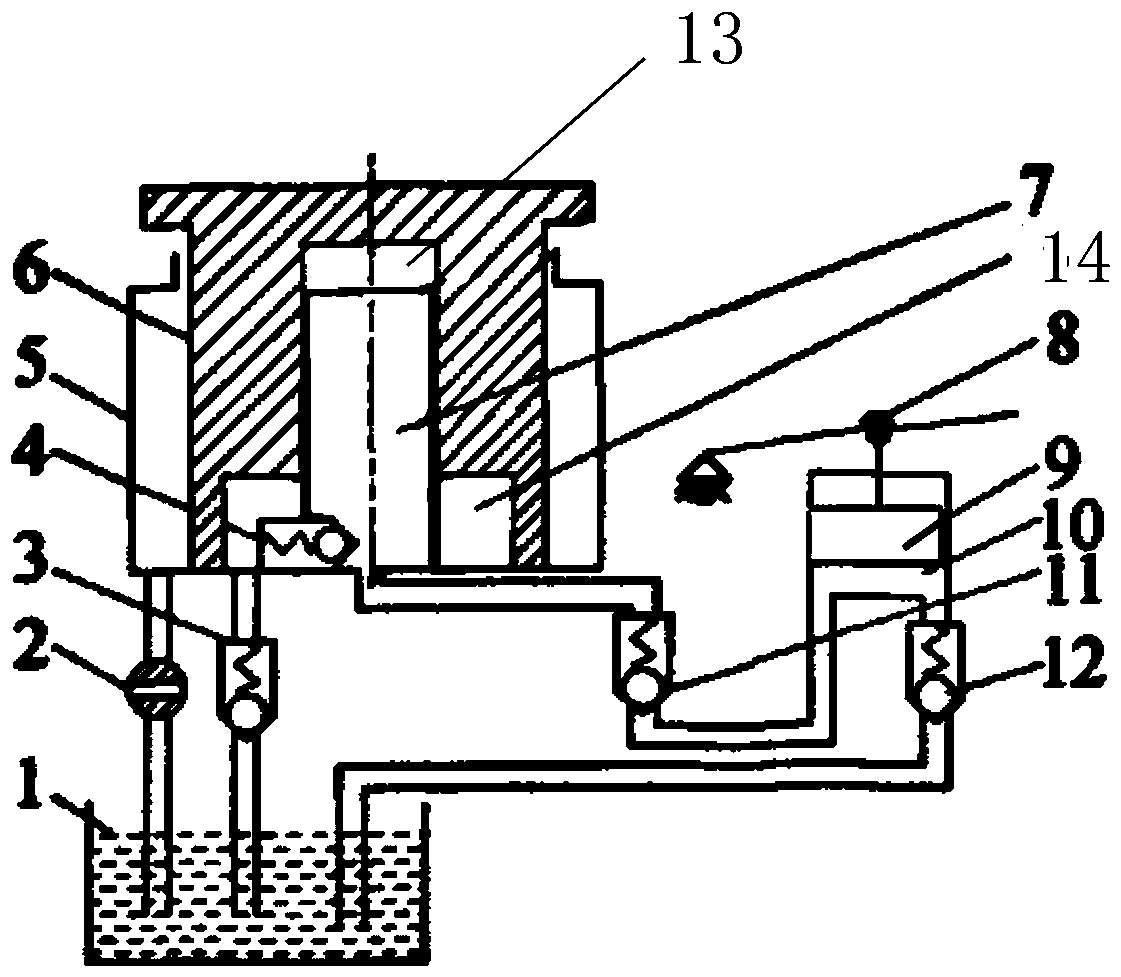

[0010] The high-efficiency hydraulic jack of the present invention includes a large cylinder plunger 6 and a pump cylinder 10, the large cylinder plunger 6 is arranged in the large cylinder barrel 5, and the lower part of the large cylinder barrel 5 is connected to the oil tank 1 through a shut-off valve 2 , the large cylinder plunger 6 is provided with a small cylinder plunger 7, the cavity of the large cylinder plunger 6 is connected with the oil tank 1 through the first check valve 3, and at the same time is connected with the pump cylinder 10 through the oil pressure check valve 11 The pump cylinder 10 is provided with a piston 9, the piston 9 is connected with the pressure rod 8 through the connecting rod, and the pump cylinder 10 is connected with the oil tank 1 through the oil suction check valve 12. The cross-sectional areas of the large cylinder plunger 6 inner cavity and the small cylinder plunger 7 are equal. The small cylinder plunger 7 is connected with the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com