Preparation method of textured coating for diamond tools based on micro-blocking method

A diamond cutting tool, diamond technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problems of difficult diamond processing, immature technology, etc., achieve high growth efficiency and success rate, and the method is simple and fast , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

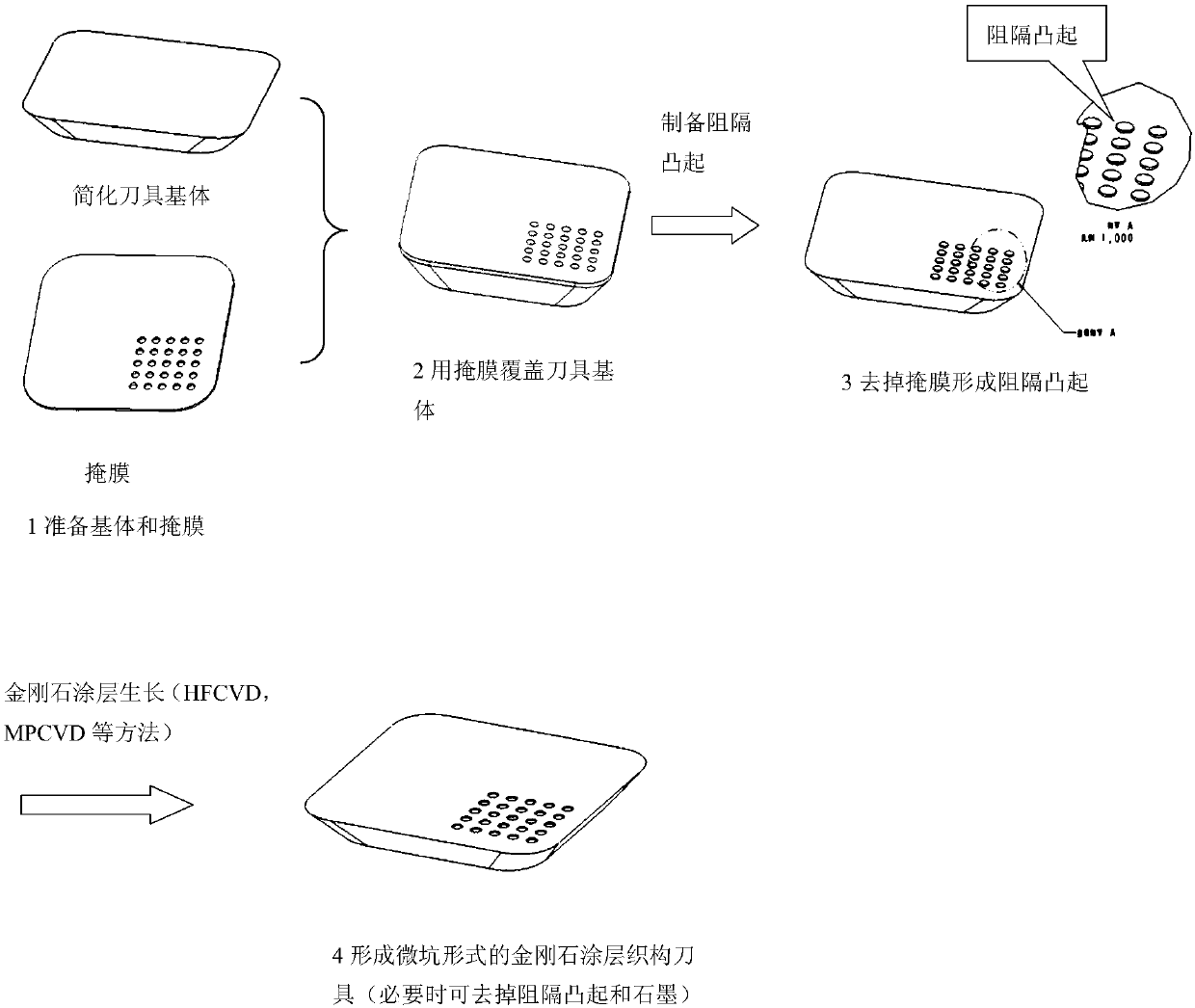

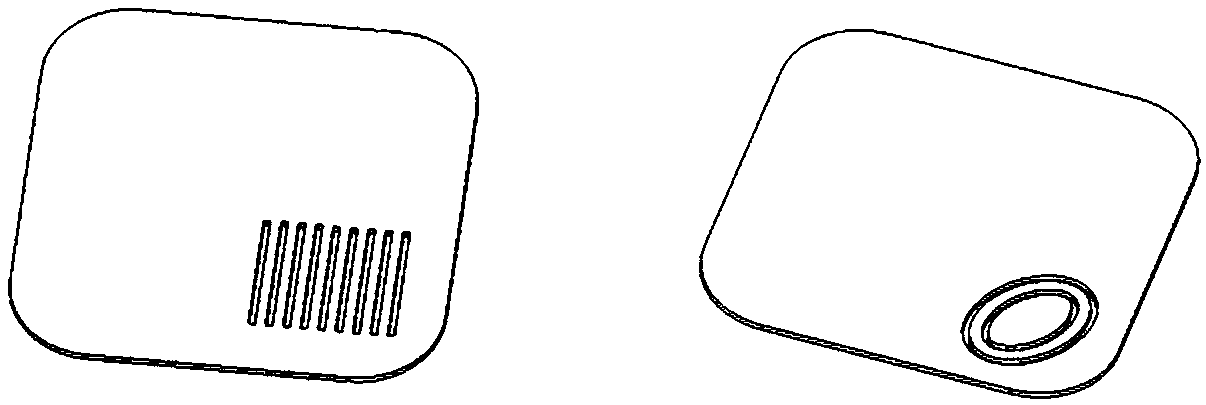

[0026] figure 1 Shown in is the tool substrate, mask, barrier protrusions, diamond coating and the resulting tool with the diamond textured coating. figure 2 Shown are masks with different textured cutouts.

[0027] A method for preparing a textured coating of a diamond tool based on a micro-area blocking method, comprising the following steps:

[0028] In the first step, the tool substrate is made of common tool materials such as cemented carbide, and undergoes pre-treatments such as deacidification and alkali removal, two-step cobalt removal or adding a transition layer, so that the surface is easy to grow a diamond coating. Roughen the tool surface so that the surface roughness is greater than 6.3 microns. The roughened tool surface is conducive to the adhesion of diamond powder and increases the adhesion of the growing diamond coating. The surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com