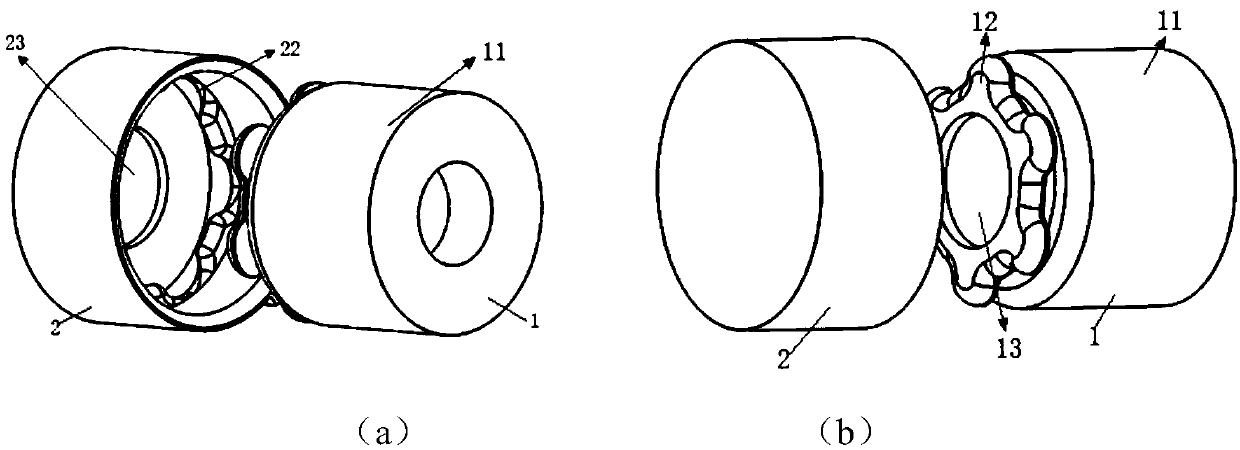

Automatic adsorption locking connection mechanism for space truss connection

A technology of space truss and connecting mechanism, applied in the direction of building structure, construction, etc., can solve the problems of difficult alignment of screw holes, influence of parts and components, complicated process, etc., and achieve the effect of firm and reliable locking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

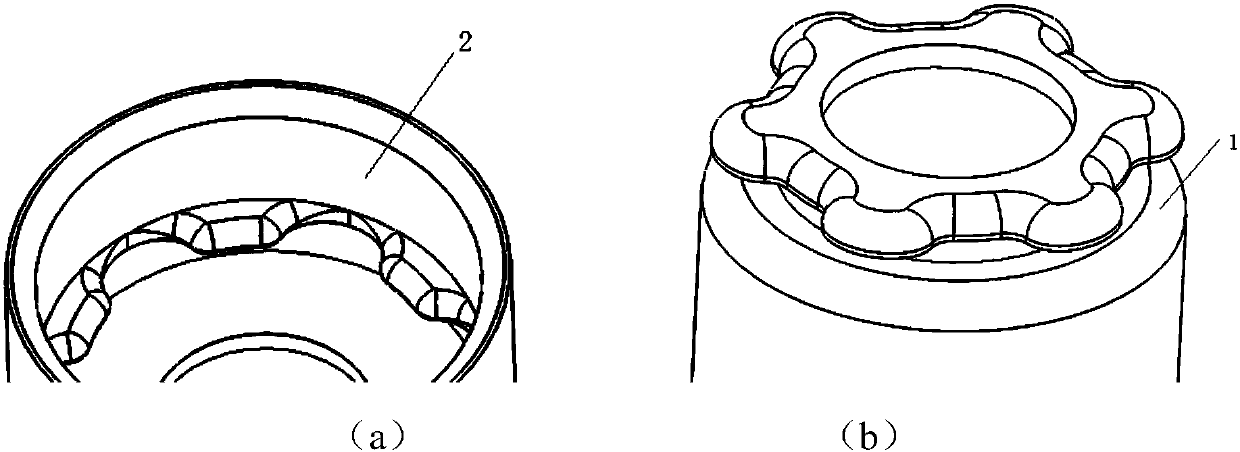

[0047] Use the "future 8000-photosensitive resin" material to print the model, with an accuracy of 0.01mm, and install magnets and rods to make a simple assembly. After physical assembly, it was found that:

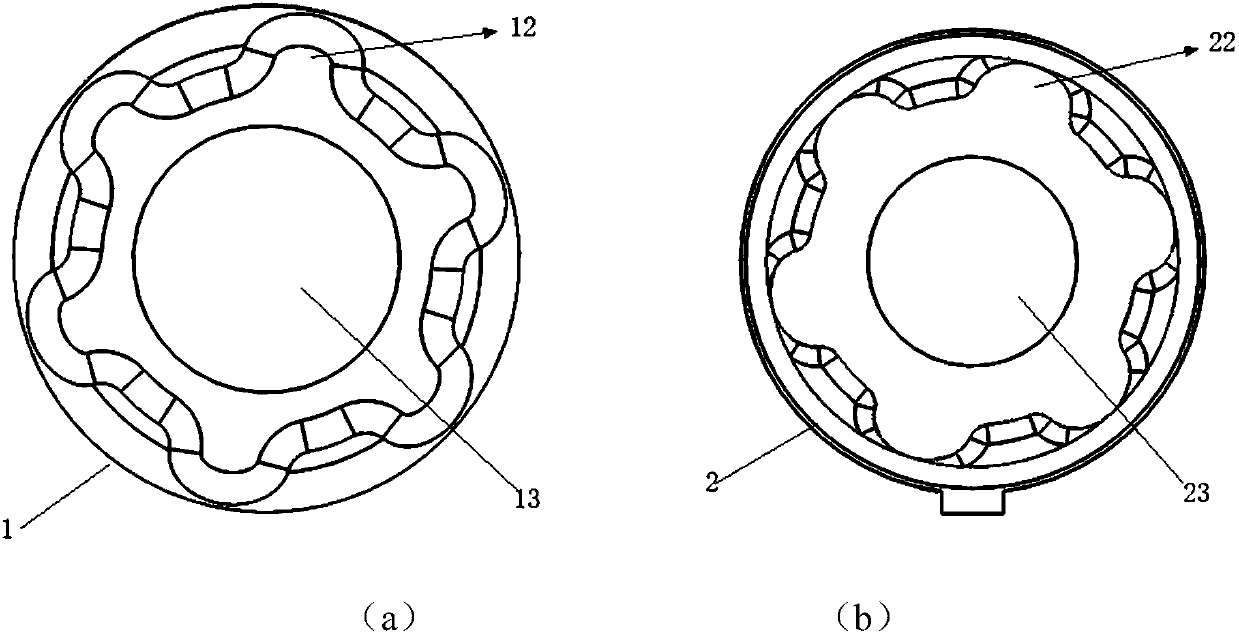

[0048] 1. The rounded corners of the "petal"-shaped protrusion 12 and the groove 22 are too small, and can only slide in automatically within a small range. If the "petal" protrusion does not correspond to the groove at all, it cannot be connected by itself;

[0049] 2. At the beginning of the design, in order to ensure that the parts can be automatically rotated and locked, and to prevent friction from being completely released from the contact surfaces, a 1mm gap is set between the contact surfaces.

[0050] After the physical connection, it was found that the 1mm gap could not allow the parts to rotate automatically, but instead made the butt joint loose and the connection became unreliable.

[0051] 3. There is no rotation locking design. After the two frames are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com